A method for recovering residual ore in a shallow hole room and pillar method stope

A recovery method and shallow hole technology, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of poor mining safety and difficult mining, eliminate hidden safety hazards in empty areas, reduce the amount of cutting engineering, and improve output. The effect of mineral grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

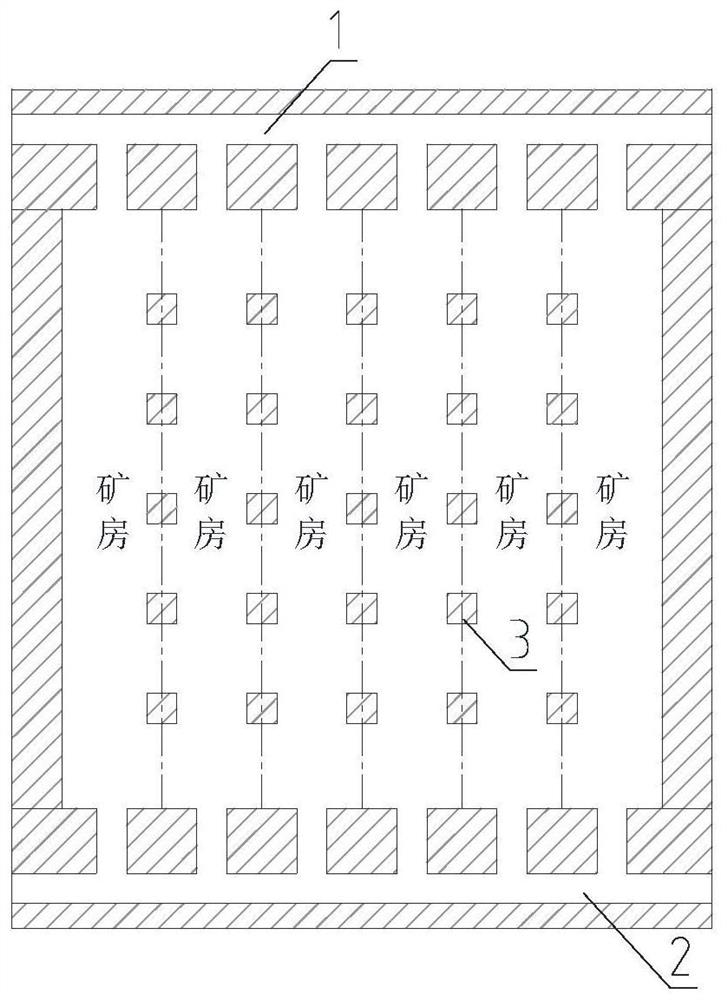

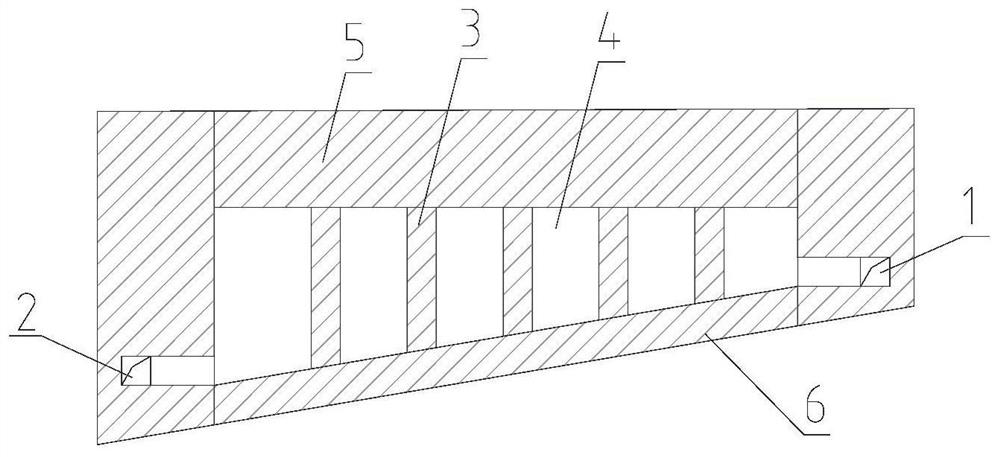

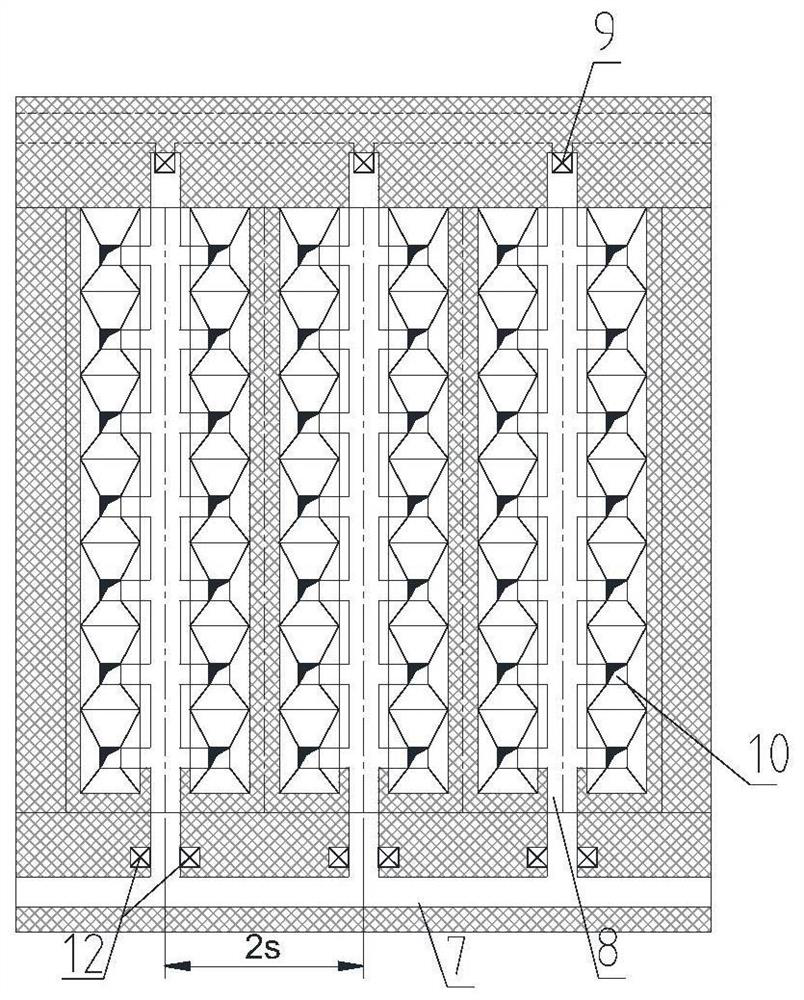

[0039] From Figure 1 - Figure 8 It can be seen that the recovery method of a shallow hole column column method according to the present invention includes the following steps:

[0040] (Step 1), use a three-dimensional laser scanner to scan the old vacuum area 4 form of the original housing column method, and the mineral span s = 8m is measured, and the old vacuum area is calculated by 4 area and volume of the old vacuum area. 4 average thickness h = 10m;

[0041] (Step 2), from the lower ramp construction contact in the mineral bottom plate surrounding rock, then travel along the mineral to the construction, the pulse transportation lane 7, the lower plate is 3m × 3m, and the pulse is 3m × 3m. Since the lower coil transporting lane 7, the distance is taken along the direction of each 16m, which is inclined to the mountain 8 to the upper stage, inclined the mountain 8 section specification 3m × 3M, inclined up the mountain 8 located in the old vacuum area 4 mineral rooms On the ce...

Embodiment 2

[0049] The method of recovery of a shallow house column method according to the present invention includes the following steps:

[0050] (Step 1), use a three-dimensional laser scanner to scan the old vacuum area 4 form of the original housing column method, and the mineral span s = 10m is measured, and the old vacuum area is calculated by 4 area and volume of the old vacuum area. 4 average thickness h = 8m;

[0051] (Step 2), from the lower ramp construction contact in the mineral bottom plate surrounding rock, then travel along the mineral to the construction, the pulse transportation lane 7, the lower plate is 3m × 3m, and the pulse is 3m × 3m. Since the lower coiled transportation lane 7 takes a distance from the direction of the upper mountain 8 to the upper stage, the upper mountain 8 is inclined to the mountain 8 section specification is 3m × 3m, and the mountain 8 is located in the old vacuum area 4 two miners. On the center, and use the people's line of Feng Ye 9 and Shan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com