A mechanized mining method of continuous large-diameter deep-hole blasting for thick and large ore bodies

A technology of deep hole blasting, thick and large ore body, applied in the direction of discharge machinery, ground mining, mining equipment, etc., can solve the problems of destroying the technical conditions of mining, unable to recover resources, difficult to deal with empty areas, etc., to protect the technical conditions of mining. , The social and environmental significance is obvious, the effect of ensuring the production capacity of the mine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

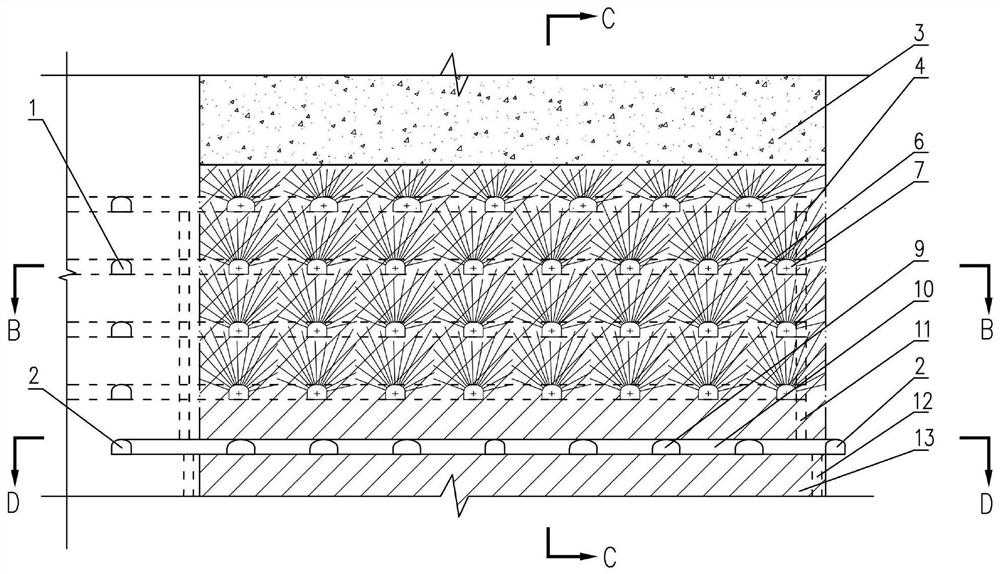

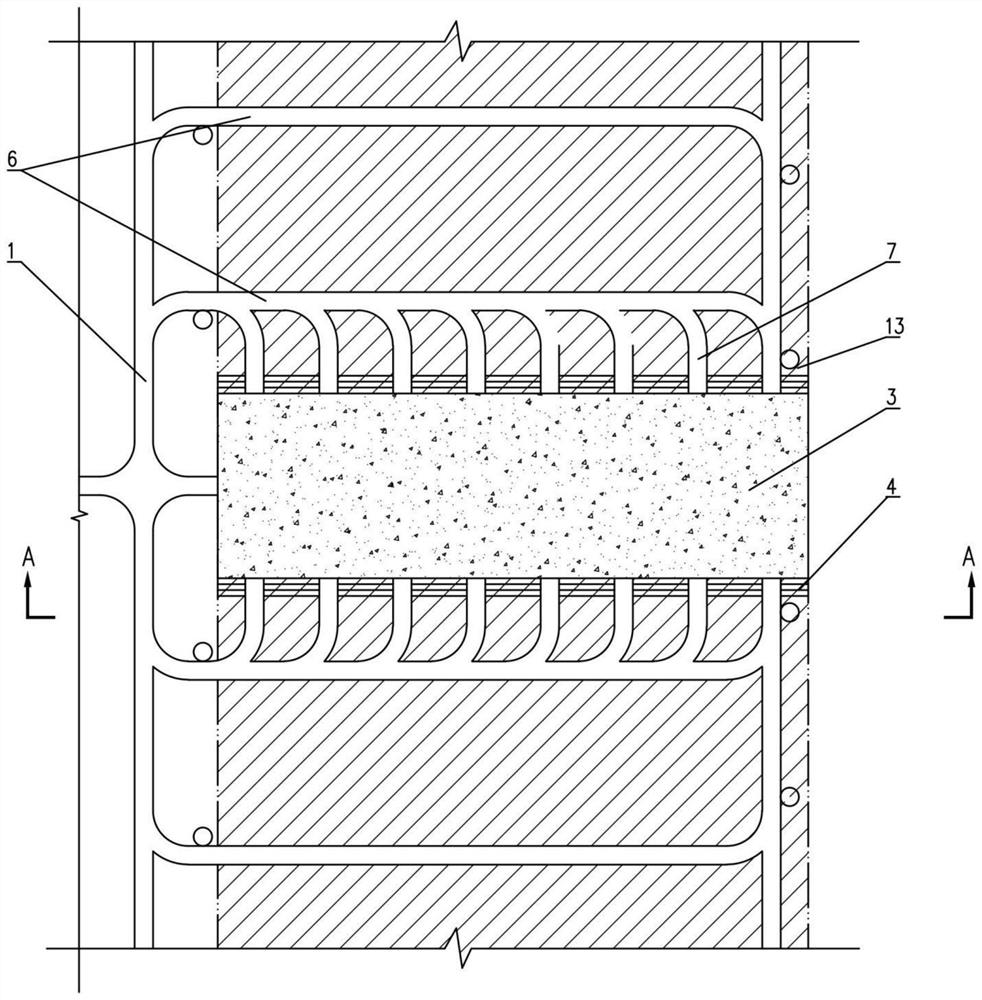

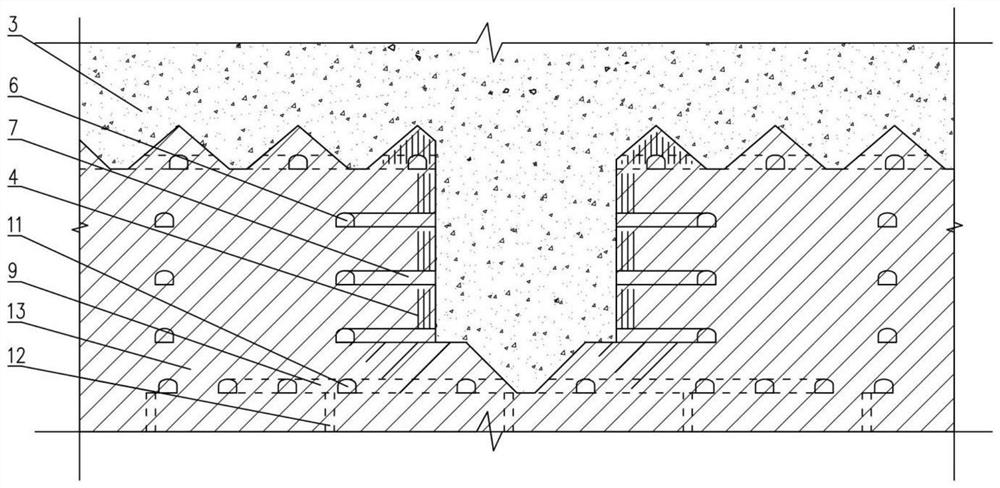

[0028] Taking the copper-iron mine in a certain area of Yunnan as an example, the ore body of the copper-iron mine has an average dip angle of 65 degrees, and the ore bed is relatively thick, with an average of about 50-80m. rock or dolomite. The original dolomite rock is relatively hard, compact, and brittle, and the ore body and stability are better. See attached Figure 1-4 show figure 1 A-A sectional view, corresponding to the attached figure 2 As shown in A-A shown in / 4, the specific steps are as follows:

[0029] Step 1. Divide ore blocks:

[0030] The ore body is divided into ore body 13 perpendicular to the ore body trend, the height of the ore block is 50-60m, the width of the ore block is 30m; the layer height is 10-15m.

[0031] Step 2. Accurate cutting:

[0032] The mining project starts construction from the middle section transportation entryway 16, and excavates the ore outlet connecting entryway 2, the central vein-piercing entryway 5 and the ore deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com