Room-and-pillar mining method for artificial barren rock pillars of gently inclined ore body

A technology of gentle inclination and mining method, applied in ground mining, mining equipment, underground mining, etc., can solve problems such as difficulty in roofing, low ore recovery rate, loss of mosaic, etc., to reduce lifting transportation costs, improve ore recovery rate, The effect of reducing the loss of dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described below with reference to the accompanying drawings, which is apparent to the embodiments of the present invention, not all of the embodiments of the present invention; Those of ordinary skill in the art will belong to the range protected by the present invention without the premise of creative labor.

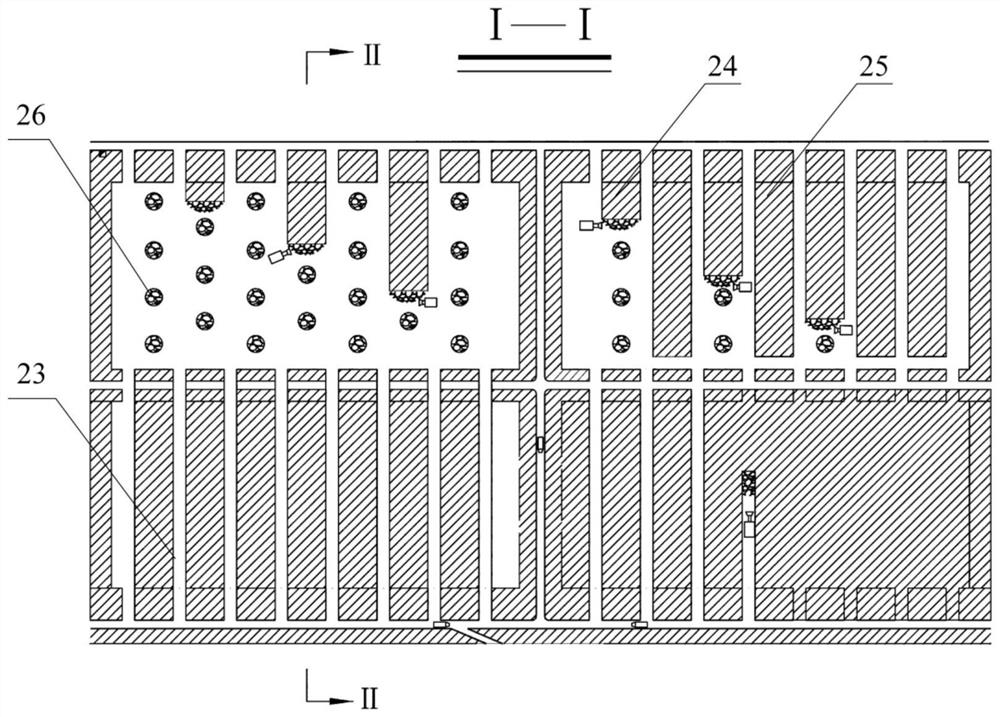

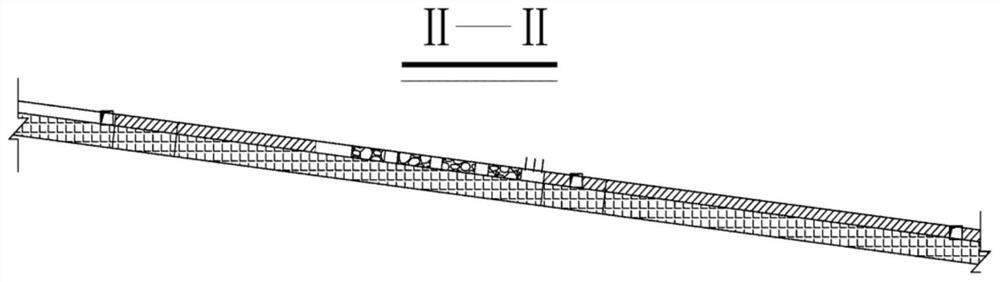

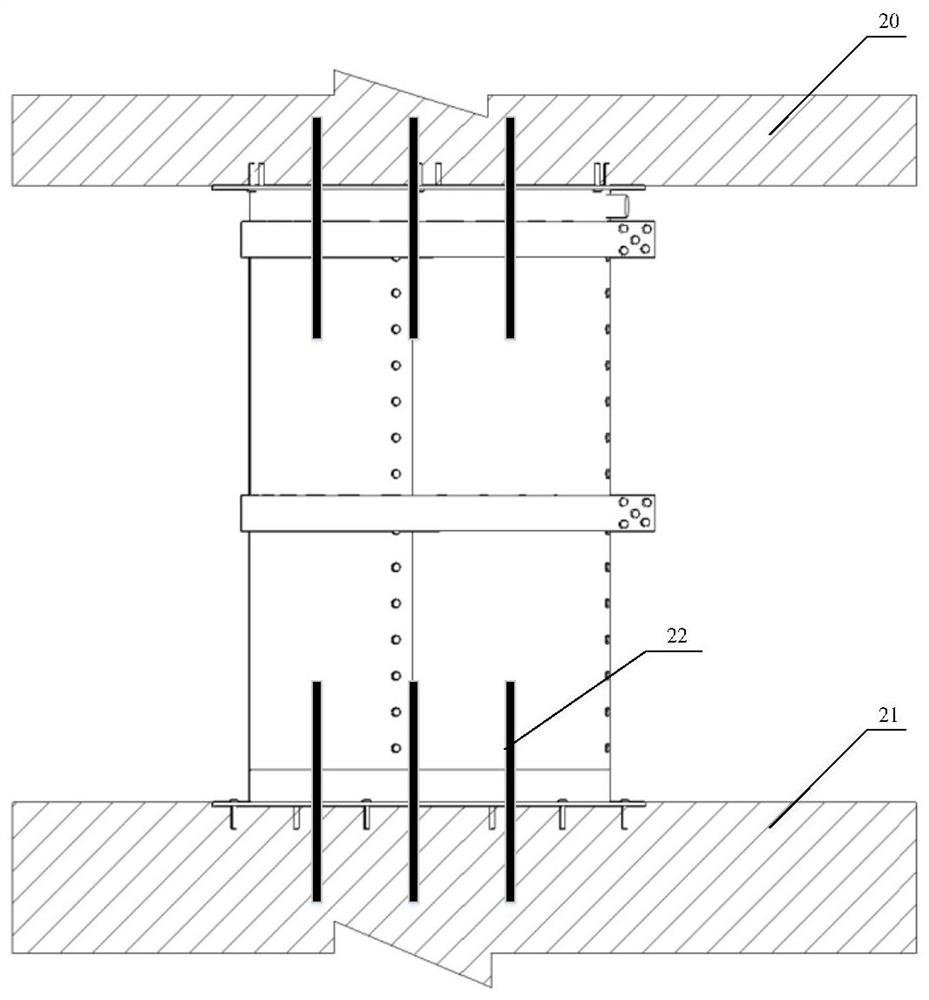

[0027] See Figure 1 - Figure 4 One of the illustrated mineral artificial waste stone pillar housing column mining method is a preferred embodiment of the present invention, and the technique according to the present invention is employed back to slowly inclined the ore body including the following steps:

[0028] (1) divide the mineral direction into a panel, and divided into one steps 24 and two steps in the panel into a step of 2 and two steps. First, go back to the strip 24, then return to the second step Strip 25. The panel length is 100-110m, one step strip 24, and the two strip 25 width is 8-10 m.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com