X-ray flat panel detector and preparation method

A flat panel detector and X-ray technology, applied in radiation intensity measurement, radiation control devices, electric solid devices, etc., to achieve the effect of reducing afterglow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

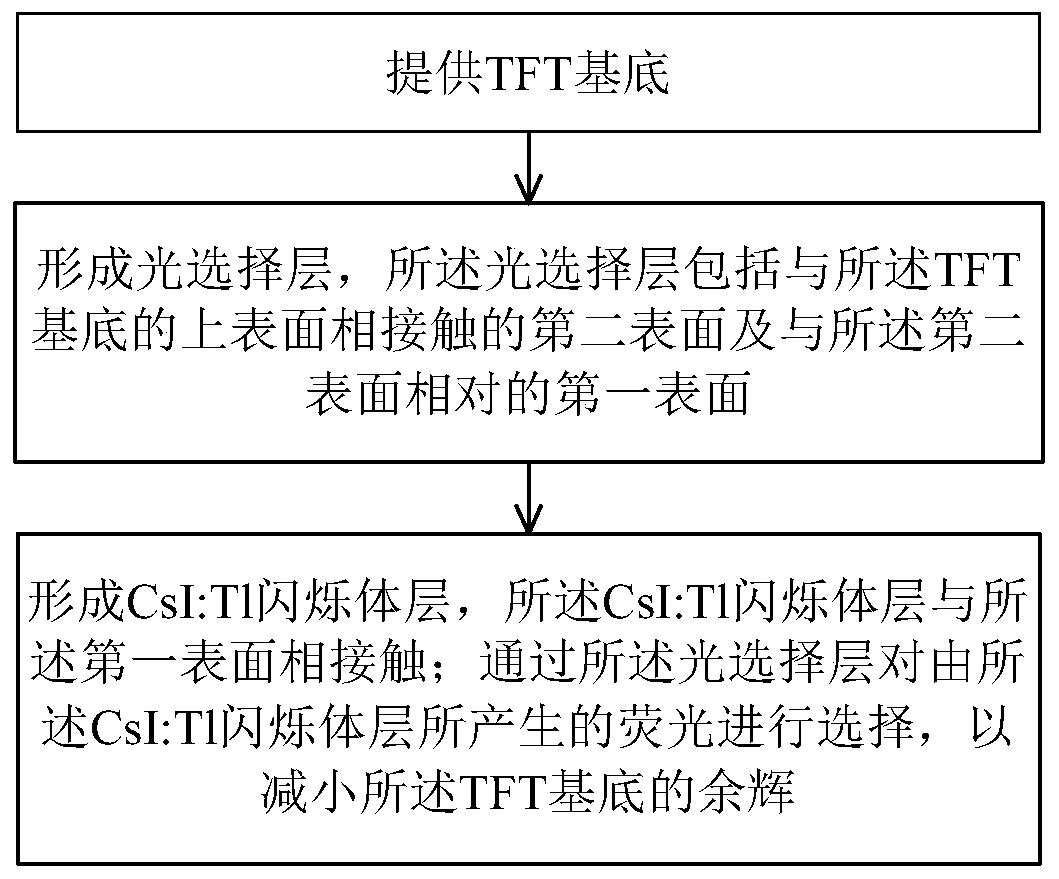

[0034] Based on the above analysis, the present invention provides a novel X-ray flat panel detector and its preparation method, which can prevent or reduce the blue light, purple light and near ultraviolet light emitted by the CsI:T1 film by absorbing or reflecting blue light, purple light and near ultraviolet light Irradiate to the TFT substrate, thereby reducing the afterglow of the TFT substrate, so as to reduce the afterglow of the X-ray flat panel detector.

[0035] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific implementation modes, and various modifications or changes can be made to the details in this specification based on different viewpoints and applications without departing from the spir...

Embodiment 2

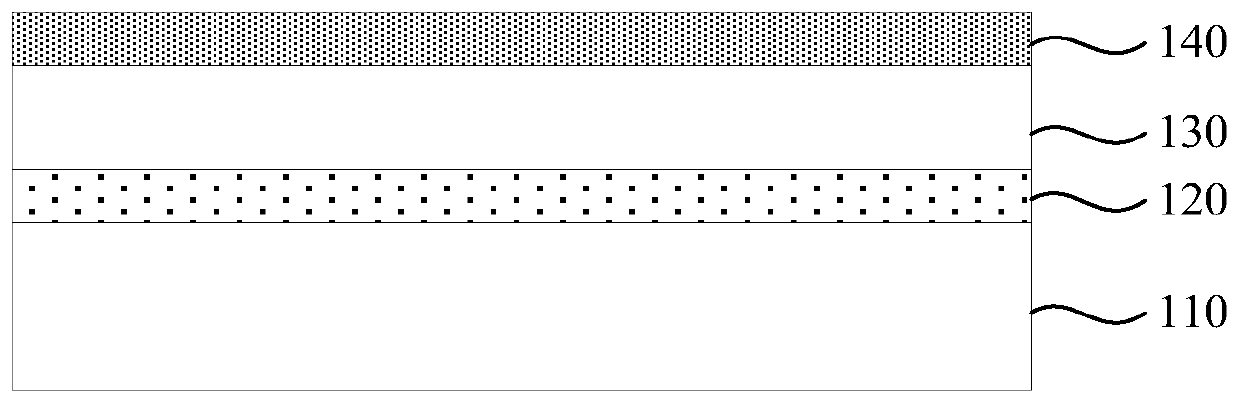

[0063] 2-1. Provide the TFT substrate mentioned in 1-1, with a thickness of 0.7mm;

[0064] 2-2. Place a piece of PVC film with a thickness of 10 μm on the TFT substrate;

[0065] 2-3. Place the CsI:Tl scintillator film with a thickness of 500 μm in 1-2 on the PVC film;

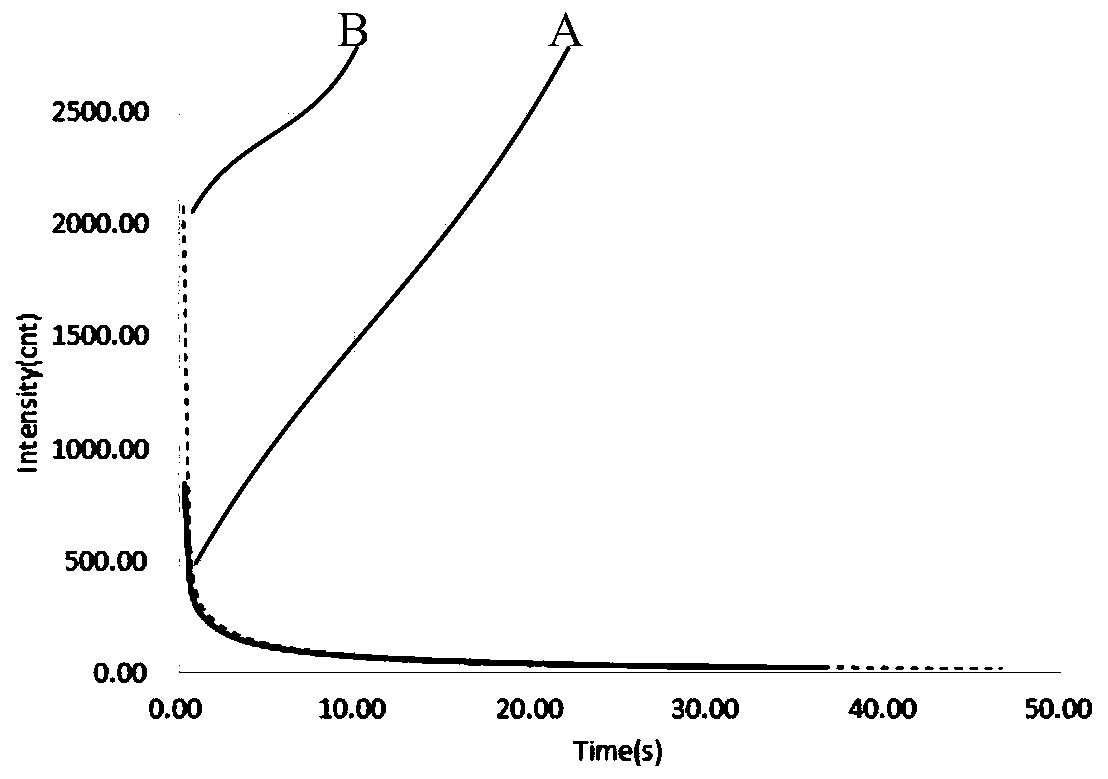

[0066] 2-4. Repeat the steps 1-3 and 1-4 to record the change of the gray value of the TFT substrate over time, such as image 3 The B curve in .

[0067] Depend on image 3 It can be seen that in the A curve, the initial value is 2085cnt; in the B curve, the initial value is 842cnt; therefore, using the X-ray flat panel detector prepared by the present invention can reduce the afterglow of the TFT substrate to the original 40 %, so that the afterglow of the TFT substrate can be effectively reduced by the light selective layer, so as to reduce the afterglow of the X-ray flat panel detector.

[0068] In summary, in the X-ray flat panel detector and the preparation method of the present invention, the photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com