A Stator Coil Forming Machine Convenient for Die Change

A stator coil and shaping machine technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of inconvenient replacement of integral molds and increase the cost of use, so as to facilitate mold replacement and reduce installation or disassembly steps, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

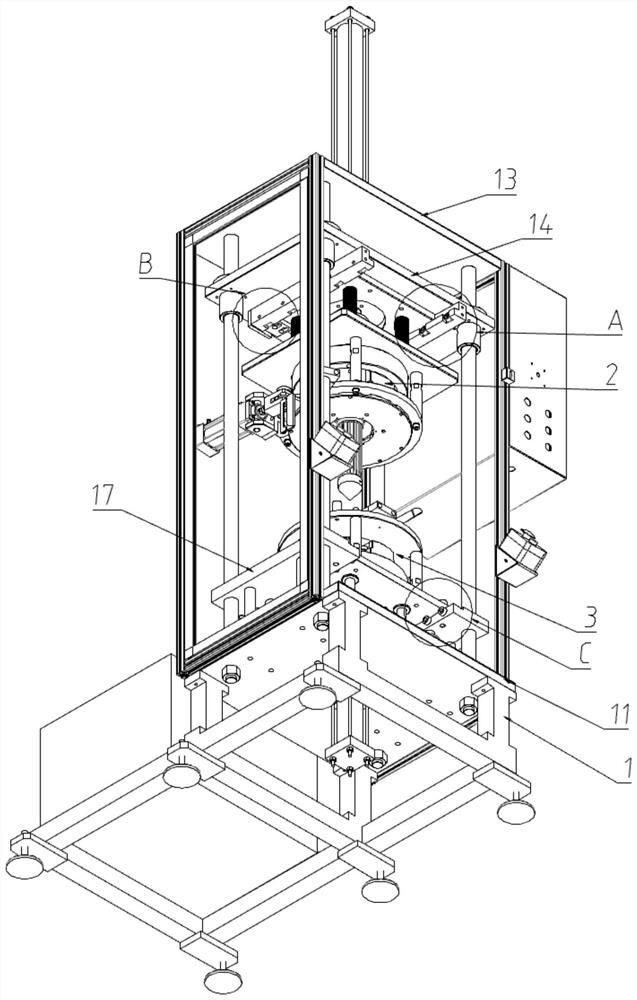

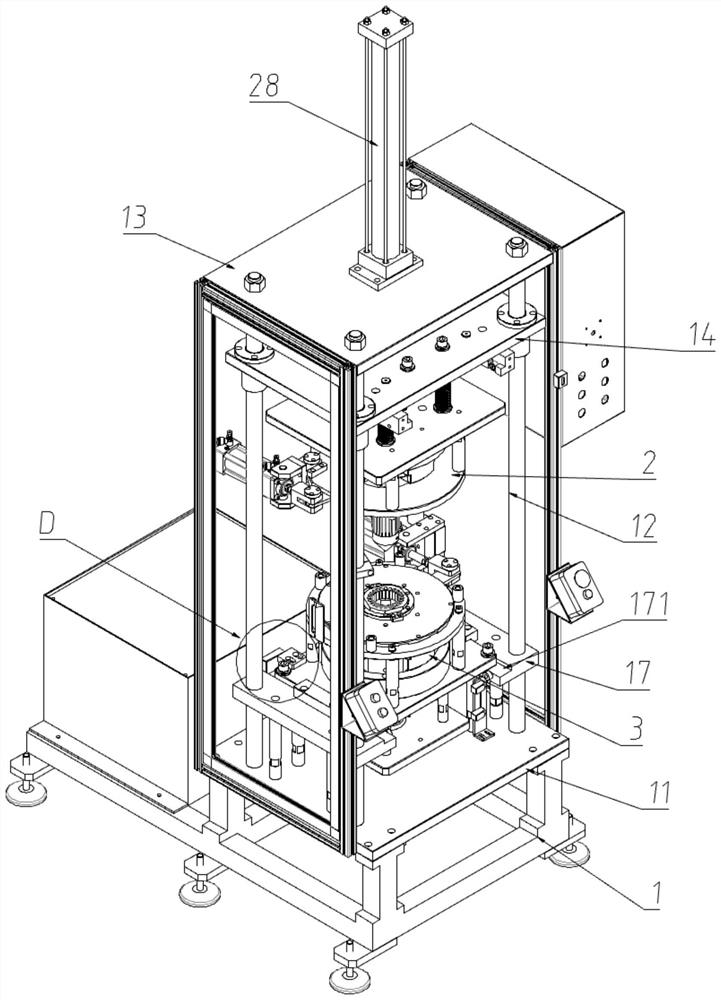

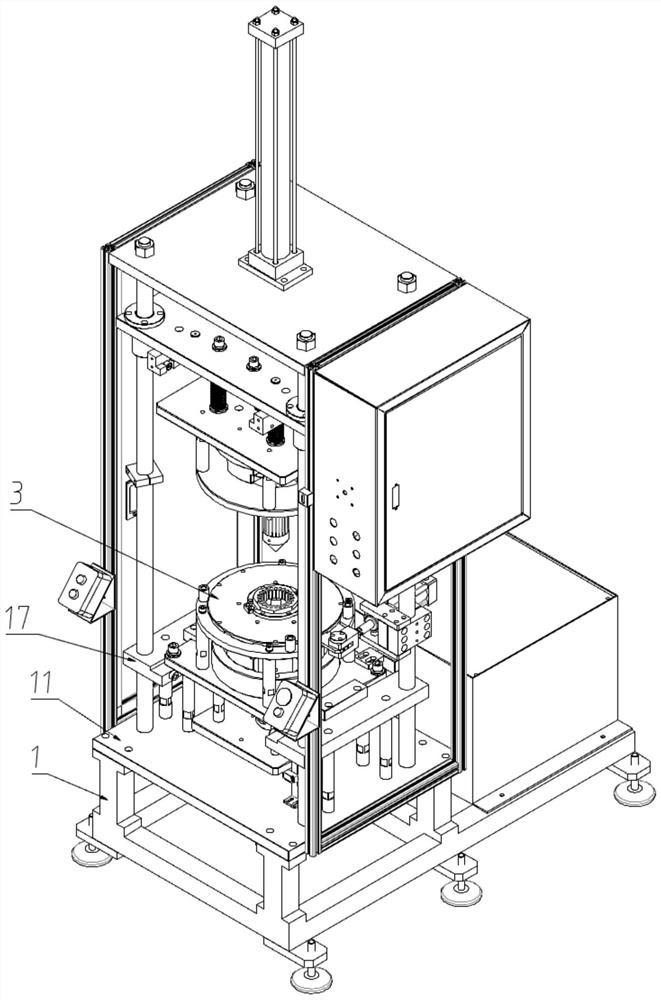

[0030] Such as Figure 1-12 As shown in the figure, a stator coil shaping machine for convenient mold change includes a frame 1 and a lower shaping mold 3 and an upper shaping mold 2 supported on the frame 1. During shaping, the stator coil 100 is placed on the lower shaping mold. After the upper mold 3 and the upper mold 2 move downward for a certain distance, the lower mold 3 and the upper mold 2 respectively shape the lower coil and the upper coil of the stator coil 100, and the specific shaping principle can be adopted The integer principle disclosed in patent 201420430915.1 can also adopt other integer principles in the prior art.

[0031] The frame 1 is provided with four columns 12 that are distribu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap