Hardware product electroplating processing system

A processing system and product technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of failure to be electroplated and uneven electroplating of hardware workpieces, and achieve the effect of facilitating electroplating and solving uneven electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

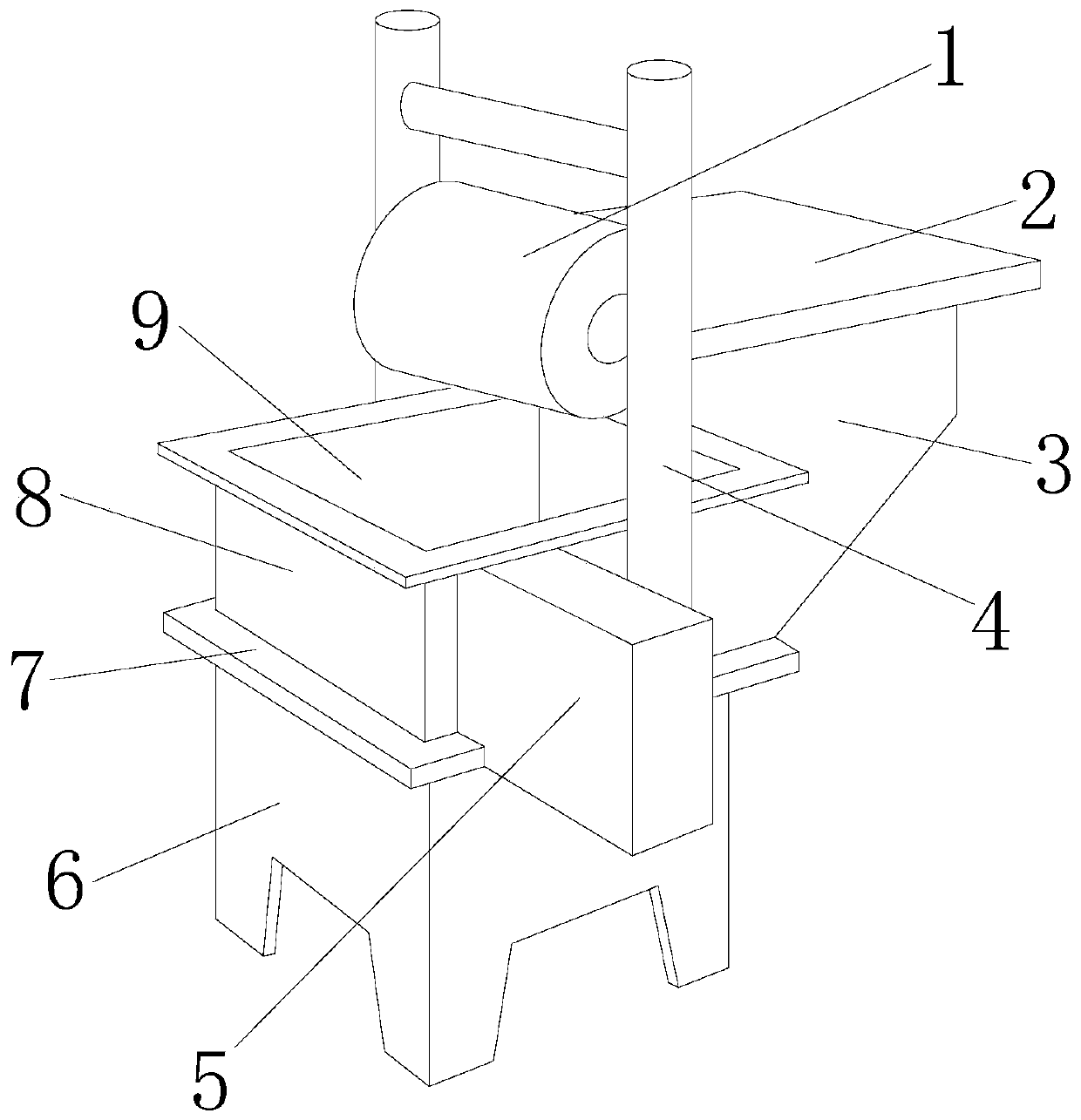

[0027] see Figure 1-Figure 6 , the present invention provides a metal product electroplating processing system, the structure of which includes a roller 1, a placement plate 2, a support block 3, a fixed frame 4, a motor box 5, a support foot 6, a connecting plate 7, a toggle device 8, and an electroplating box 9 , the roller 1 is installed on the fixed frame 4, the fixed frame 4 is mechanically welded with the connecting plate 7, the connecting plate 7 is located on the top of the supporting foot 6, the supporting foot 6 is fixedly connected with the connecting plate 7, and the connecting plate 7 An electroplating box 9 is arranged on the plate 7, a toggle device 8 is arranged in the electroplating box 9, the support block 3 is connected with the connecting plate 7, and a placement plate 2 is fixedly arranged on the support block 3;

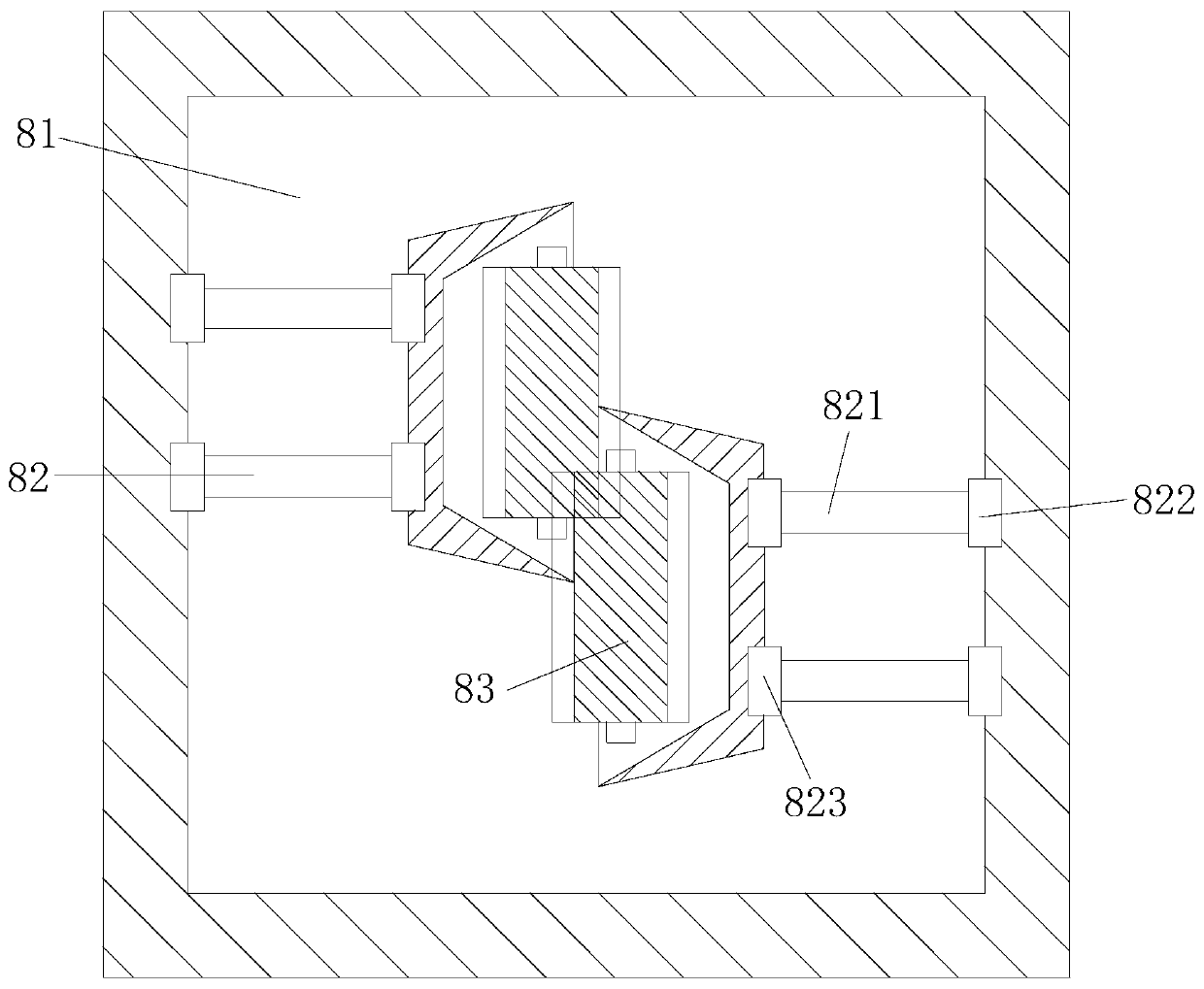

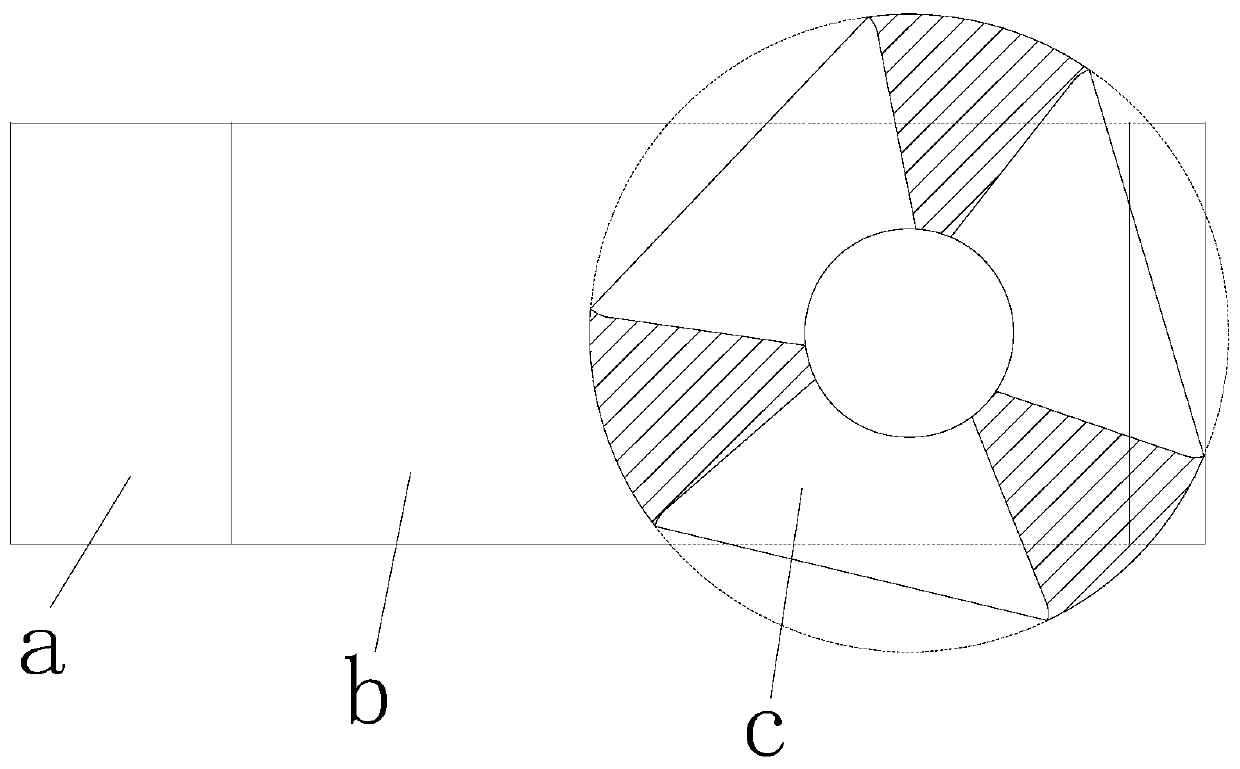

[0028] The toggle device 8 is composed of an electroplating bin 81, a connecting unit 82, and a toggle unit 83. The electr...

Example Embodiment

[0037] Example 2

[0038] see Figure 1-Figure 4 , the present invention provides a metal product electroplating processing system, the structure of which includes a roller 1, a placement plate 2, a support block 3, a fixed frame 4, a motor box 5, a support foot 6, a connecting plate 7, a toggle device 8, and an electroplating box 9 , the roller 1 is installed on the fixed frame 4, the fixed frame 4 is mechanically welded with the connecting plate 7, the connecting plate 7 is located on the top of the supporting foot 6, the supporting foot 6 is fixedly connected with the connecting plate 7, and the connecting plate 7 The plate 7 is provided with an electroplating box 9, and the electroplating box 9 is provided with a toggle device 8, the support block 3 is connected with the connecting plate 7, and the support block 3 is fixedly provided with a placement plate 2; the dial The moving device 8 is composed of an electroplating bin 81, a connecting unit 82, and a toggle unit 83. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap