Wafer tray marking method and structure thereof

A disk structure and wafer technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of high temperature of baking, separation of wafer holder, user troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

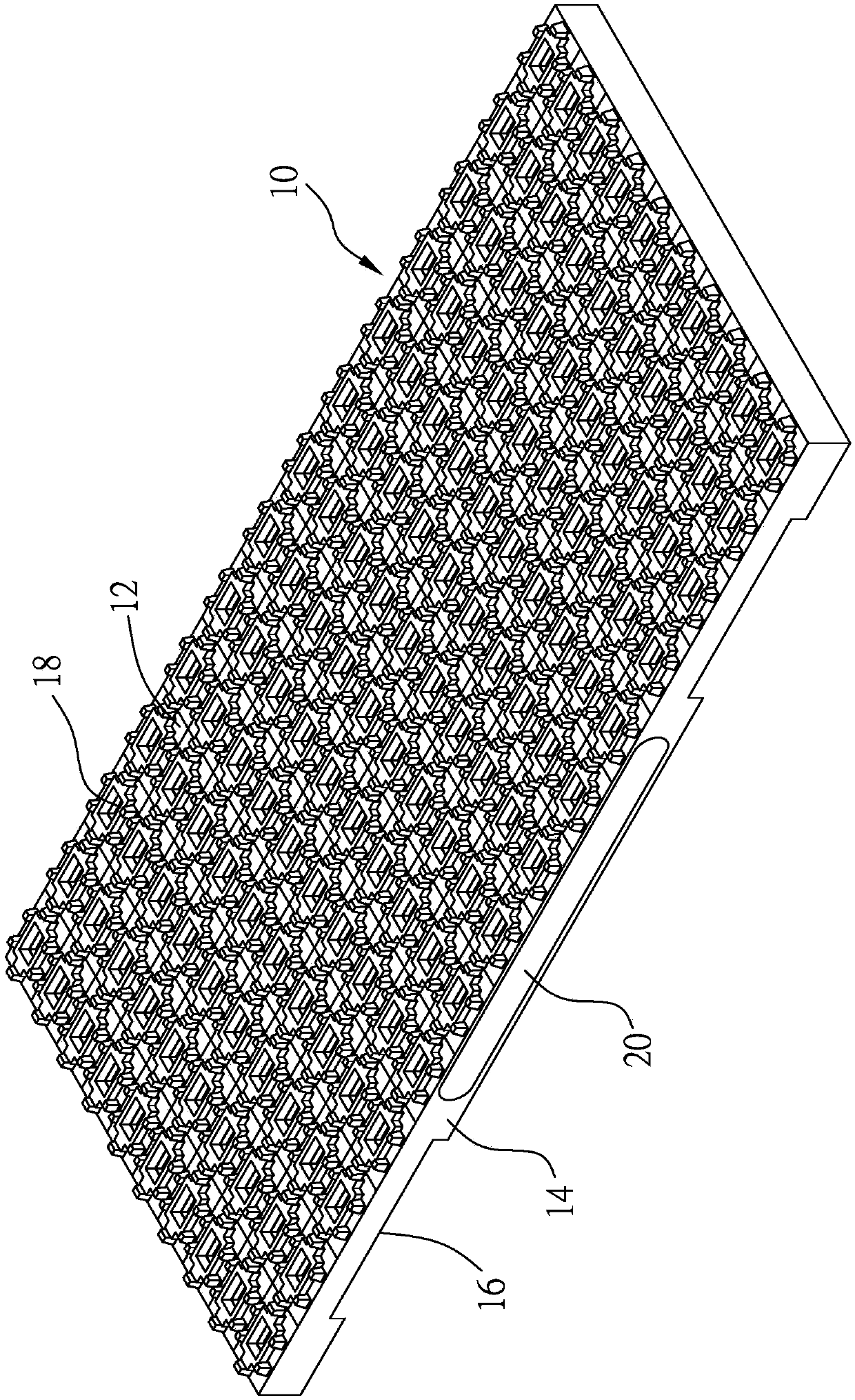

[0027] see figure 1 , is a wafer chuck structure provided by a preferred embodiment of the present invention, which includes a chuck body 10 and a coating layer 20 .

[0028] The support plate body 10 is a rectangular plate shape. The support plate body 10 has a bearing surface 12, a peripheral surface 14 and a bottom surface 16. The bearing surface 12 is opposite to the bottom surface 16. The peripheral surface 14 is located between the bearing surface 12 and the bottom surface 16 Between the bottom surface 16 and the peripheral surface 14 connects the carrying surface 12 and the bottom surface 16 . The tray body 10 further has a bearing portion 18 formed on the bearing surface 12 and extending toward the bottom surface 16 .

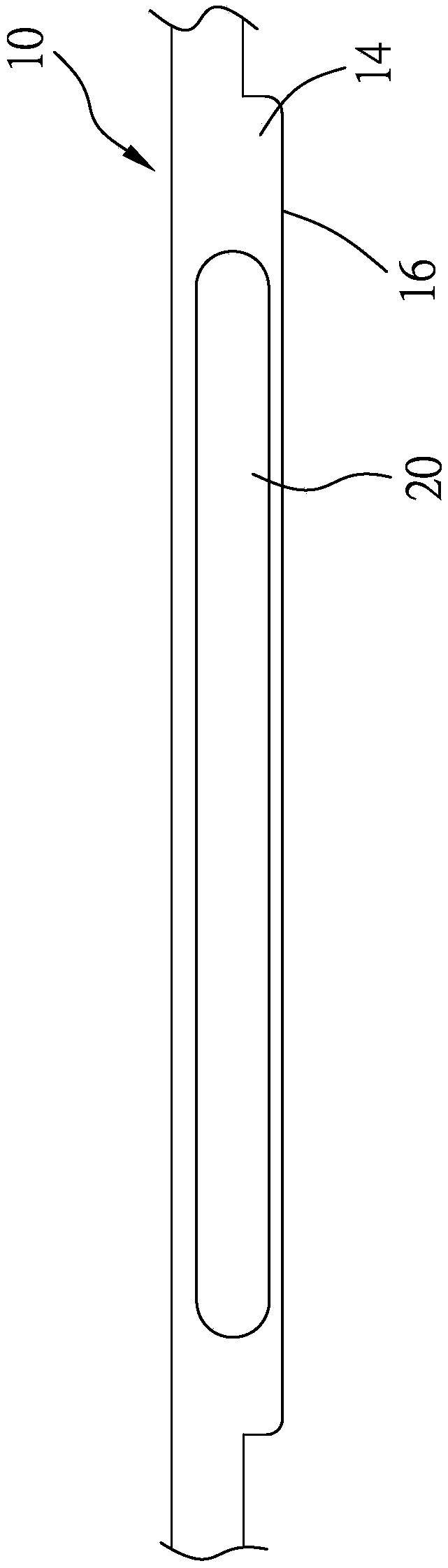

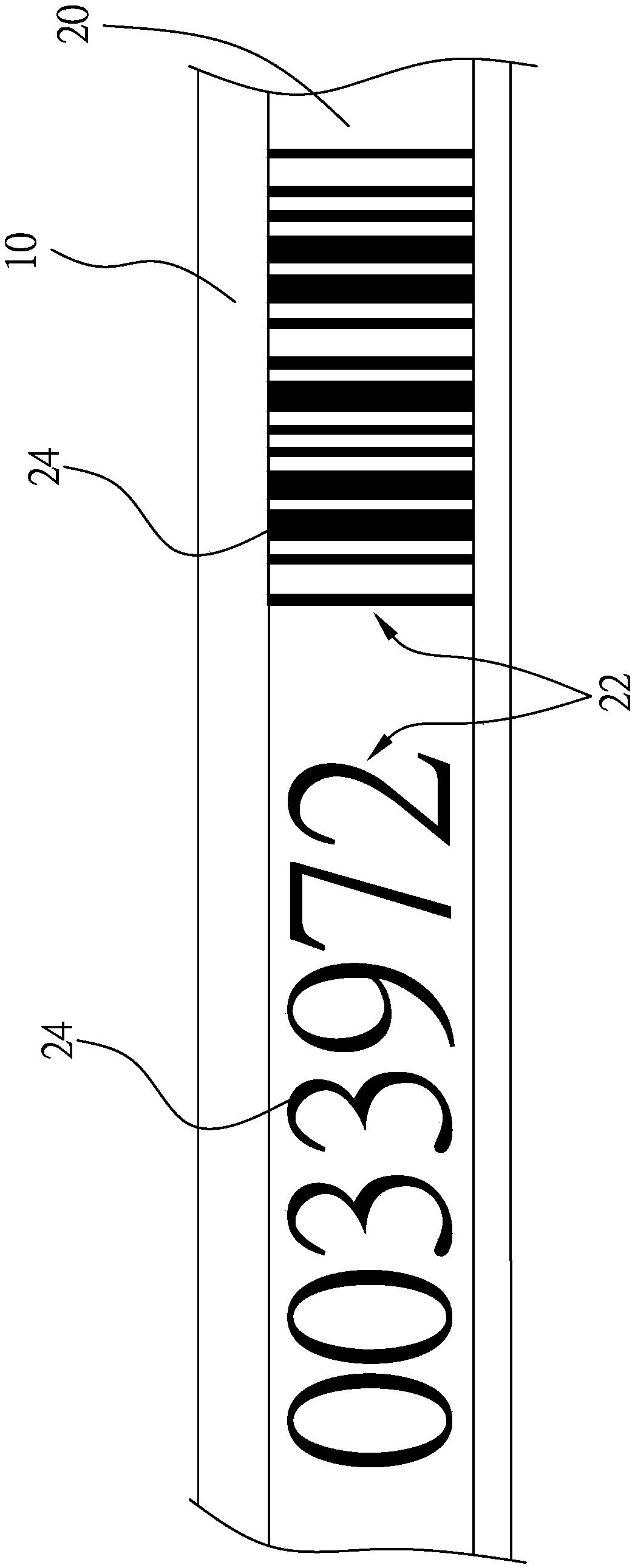

[0029] see figure 2 , the coating layer 20 is disposed on the peripheral surface 14 or the bottom surface 16 of the susceptor body 10 . In this embodiment, the coating layer 20 may be disposed on the peripheral surface 14 of the susceptor body 10 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com