Air-water mixed belt cleaner

A belt cleaner and feng shui technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of short service life of the conveyor belt, scraping of the conveyor belt, etc., to prolong the service life, avoid mechanical friction, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

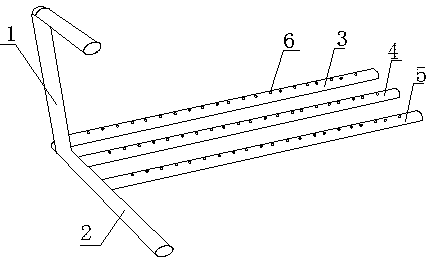

[0010] Fengshui mixed belt cleaner is composed of water pipe, high-pressure air pipe, the first Fengshui mixing pipe, the second Fengshui mixing pipe and the third Fengshui mixing pipe. The feng-shui mixing pipe, the second feng-shui mixing pipe and the third feng-shui mixing pipe are respectively connected to the transverse surface of the high-pressure air pipe and arranged in parallel. The first feng-shui mixing pipe, the second feng-shui mixing pipe and the third The air-water mixing pipe is evenly provided with spray holes.

[0011] The included angle between the nozzle hole of the present invention and the horizontal direction is 35-40 0 .

[0012] The middle part of the water pipe of the present invention is bent into a right angle.

[0013] The working process of the present invention is as follows: first, a piece of unpressurized water and high-pressure air (pressure 0.3-0.4MPa) are mixed into a sealed pipeline with a diameter of 1 inch, and a ∮1.5 pipe is drilled ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com