Optical centering and edging fixture for plano-convex cylindrical mirror, and optical centering and edging method

A plano-convex cylindrical mirror and edging technology, applied in the field of optics, can solve the problem that the processing efficiency cannot reach the best state, and achieve the effect of reducing the CNC processing technology, improving the production efficiency and quality, and ensuring the center deviation parameter index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

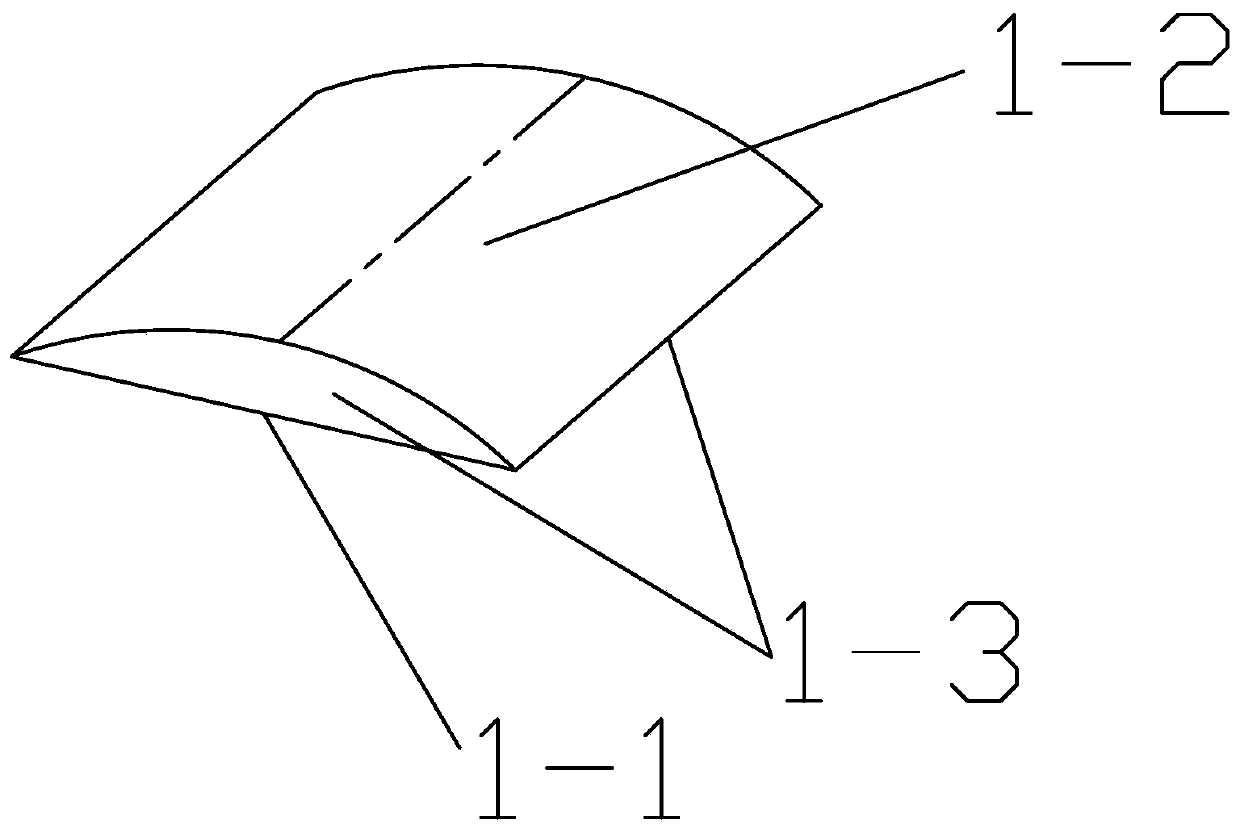

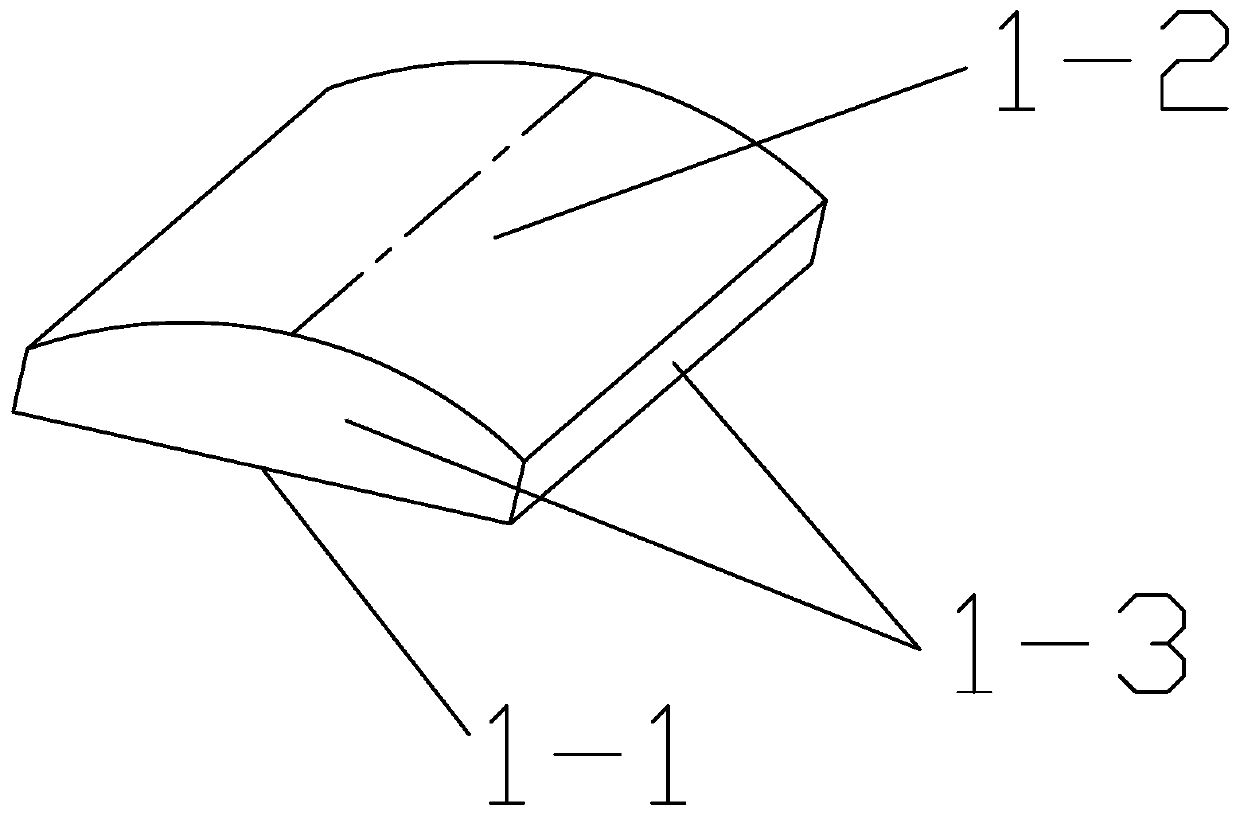

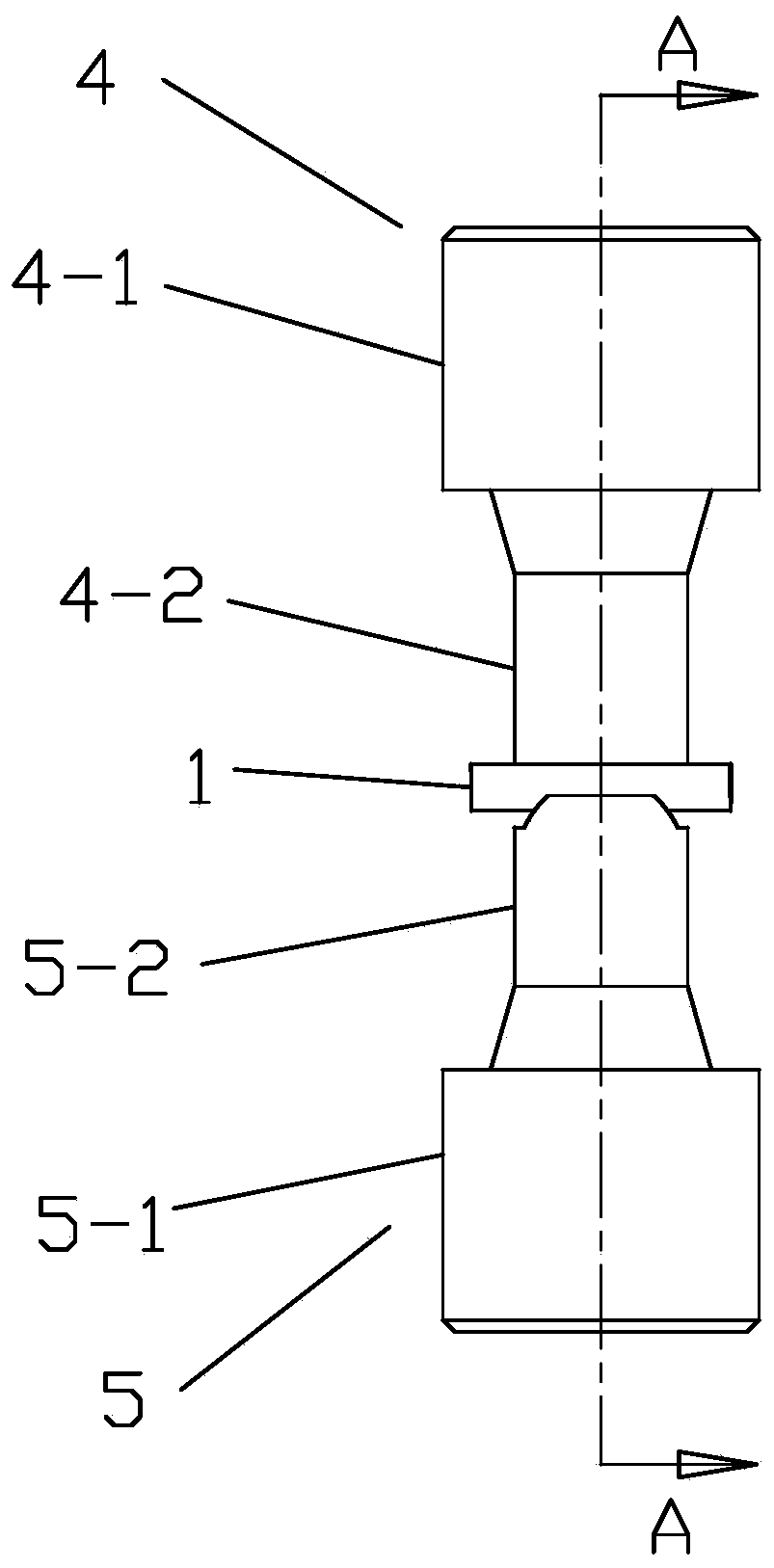

[0046] Such as Figure 1-7 As shown, an optical centering and edging fixture of a plano-convex cylindrical mirror, the optical centering and edging fixture of a plano-convex cylindrical mirror includes a first clamping assembly 4 and a second clamping assembly that are opposite and coaxially arranged The holding assembly 5; the first holding assembly 4 includes the first seat cover 4-1 fixed on the optical centering edger and the first clamping sleeve connected to the axial end of the first seat cover 4-1 The barrel 4-2, the first seat cover 4-1 is provided with a first fixing hole 4-1-1 extending in the axial direction for installation and connection with the optical centering and edging instrument. A clamping sleeve 4-2 is provided with a first light passage 4-2-1 extending in the axial direction, the first fixing hole 4-1-1 and the first light passage 4- 2-1 Interpenetrating and coaxial arrangement;

[0047] The second clamping assembly 5 includes a second seat cover 5-1 fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap