Impeller disassembling and assembling device, impeller disassembling and assembling method and impeller installation method

A technology of impeller and hydraulic device, which is applied in the field of impeller disassembly and assembly devices, which can solve the problems of difficulty in impeller installation and disassembly, low efficiency, and component damage, and achieve the effect of simple structure, convenient use, and precise installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

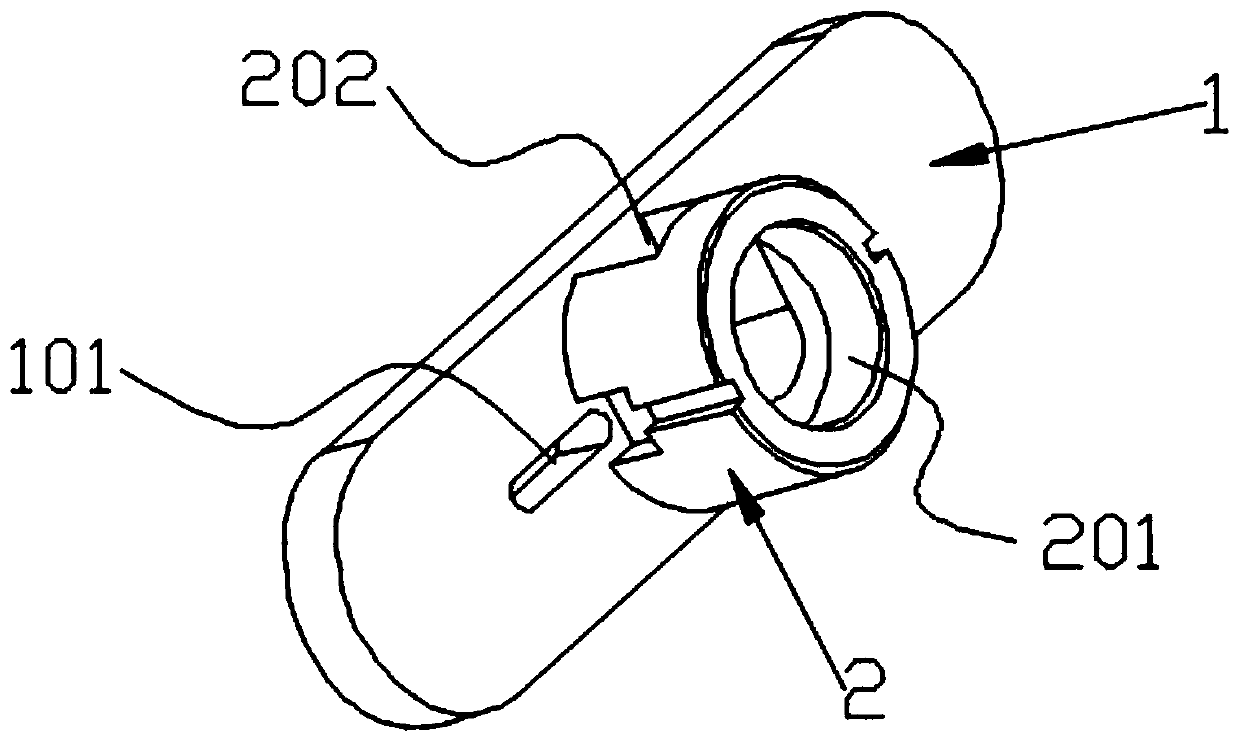

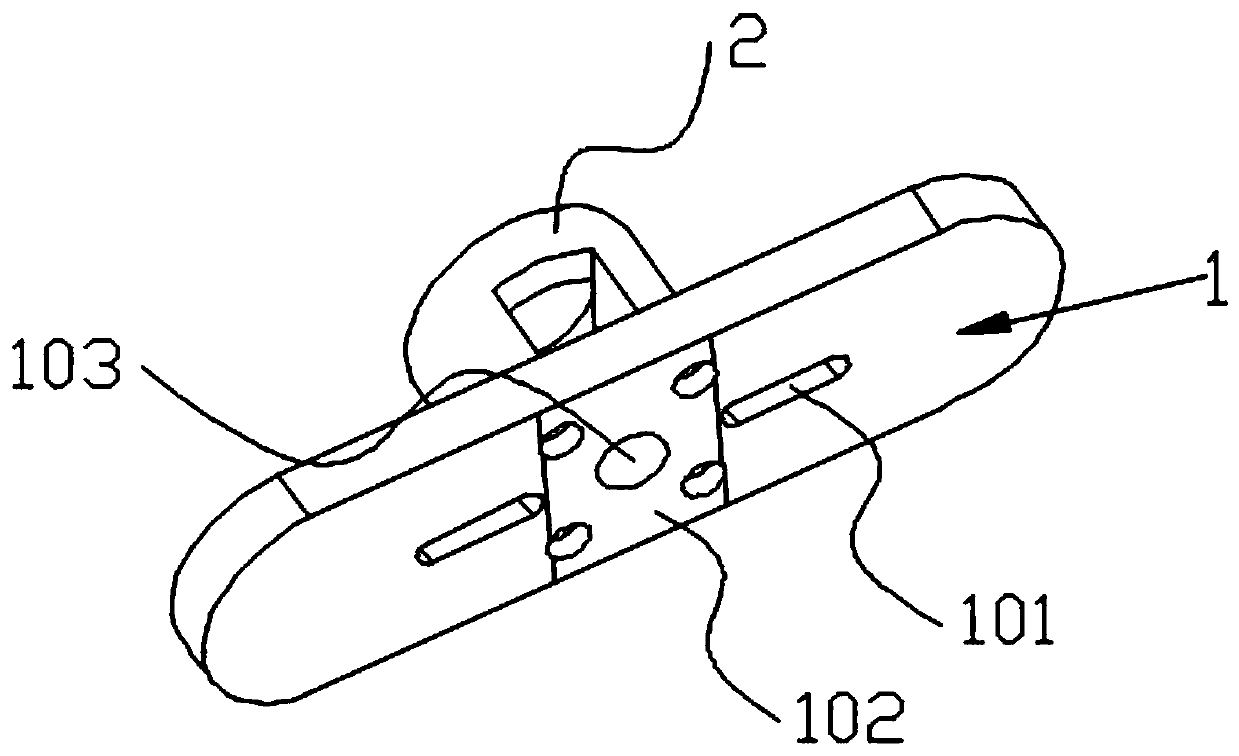

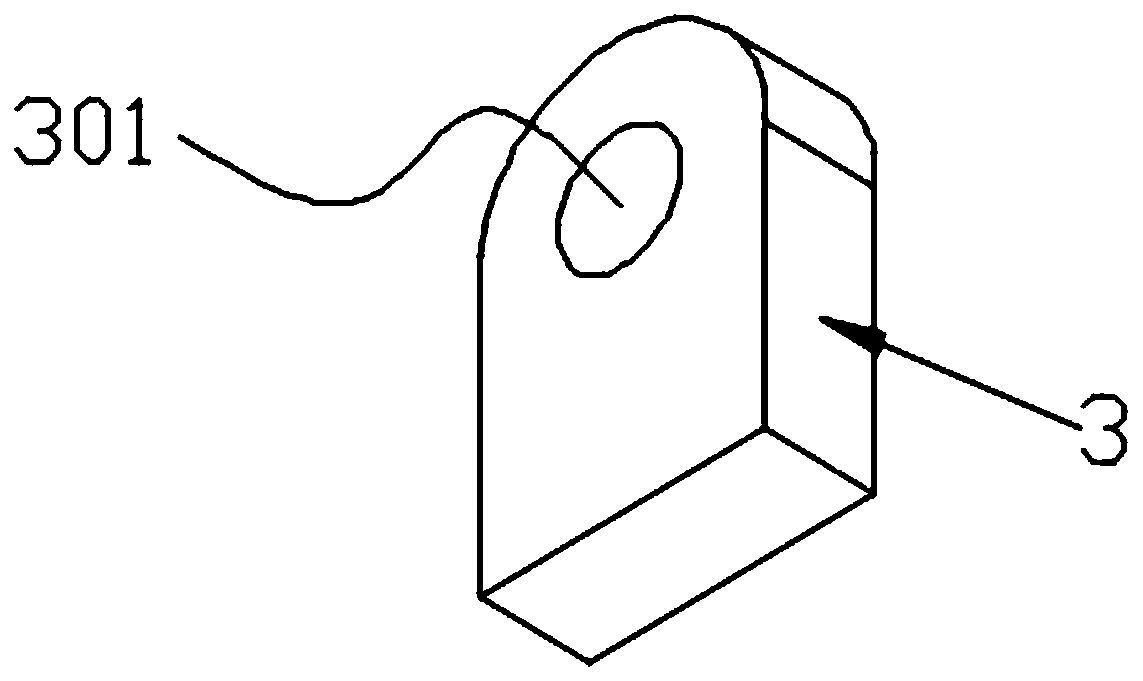

[0044] Such as Figure 1-Figure 5 As shown, an impeller disassembly device has two functions of disassembly and installation, including a pressure plate 1, a fixed seat 2 detachably connected to the pressure plate 1, and a moving plate 3 embedded in the fixed seat 2 The side of the fixed seat 2 close to the pressing plate 1 is provided with a receiving groove 202 for accommodating the moving plate 3, the depth of the receiving groove 202 is greater than the thickness of the moving plate 3, and the side of the fixing seat 2 far away from the pressing plate 1 A mounting hole 201 for connecting the hollow hydraulic device 4 (hollow hydraulic cylinder) connected to the housing groove 202 is provided on the side, the inner diameter of the mounting hole 201 is larger than the width of the housing groove 202, and a first Through hole 301, the pressure plate 1 is provided with a second through hole 103, and the central axes of the installation hole 201, the first through hole 301 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com