A Periodic Piezoelectric Beam Structure with Active Vibration and Noise Reduction Functions

An active vibration reduction, vibration reduction and noise reduction technology, applied to truss structures, joists, girders, etc., can solve the problems of inability to actively control the vibration band gap frequency range of beam structures, poor vibration and noise reduction effects, etc., to achieve good Effects of vibration reduction and noise reduction, increased bandgap range, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

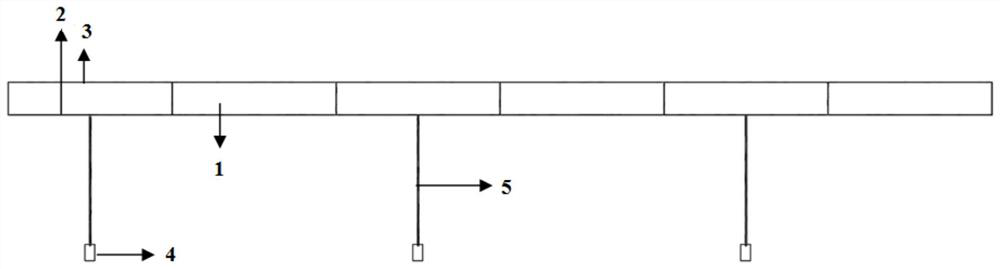

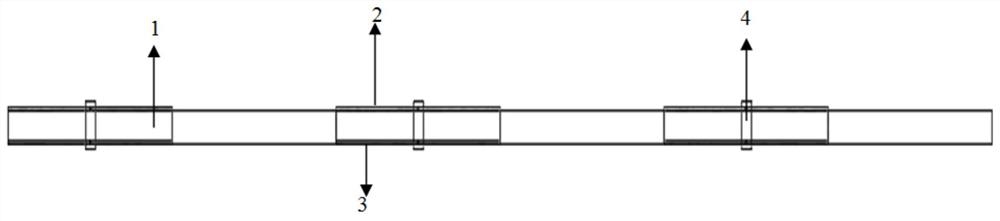

[0019] Specific implementation mode one: refer to figure 1 and image 3 Describe this embodiment. This embodiment provides a periodic piezoelectric beam structure with active vibration and noise reduction functions. The beam structure includes a base beam 1 and N vibration and noise reduction units, where N is a positive integer and N The vibration and noise reduction units are installed equidistantly on the base beam 1 along the length direction of the base beam 1 .

[0020] In this embodiment, N vibration and noise reduction units are equidistantly installed on the base beam 1 along the length direction of the base beam 1, which is to optimize the original base beam 1 into a beam with periodically distributed vibration and noise reduction units. structure, and make it have the characteristics of a periodic beam structure, with vibration bandgap characteristics, in preparation for the adjustment of the vibration bandgap by the subsequent vibration and noise reduction unit, t...

specific Embodiment approach 2

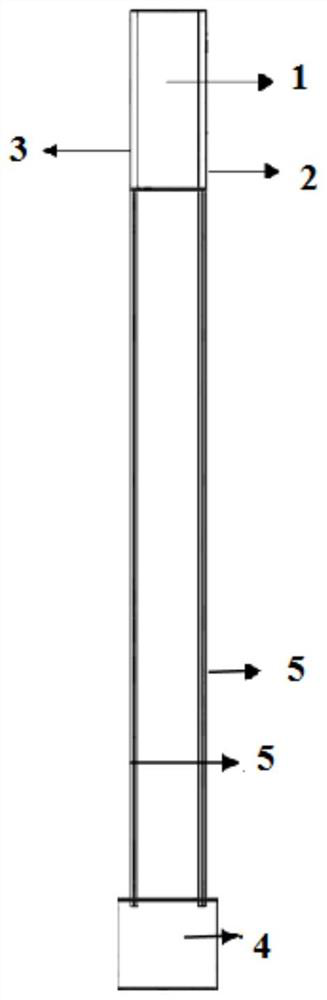

[0021] Specific implementation mode two: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment is to further limit the vibration and noise reduction unit described in the first specific embodiment. In this embodiment, the vibration and noise reduction unit includes a piezoelectric sensor 2 and a piezoelectric actuator 3 , the controller 4 and four wires 5, the negative signal input end of the piezoelectric sensor 2 is attached to a side wall of the base beam 1, the positive signal output end and the negative signal input end of the piezoelectric sensor 2 are respectively connected to each other through a wire 5 The signal input ends of the controller 4 are connected, the negative action output end of the piezoelectric actuator 3 is attached to the other side wall of the base beam 1, the negative action output end and the positive signal input end of the piezoelectric actuator 3 are respectively It is connected to the signal output terminal of the controller ...

specific Embodiment approach 3

[0023] Specific implementation mode three: refer to Figure 1 to Figure 3 This embodiment is described. This embodiment is to further limit the piezoelectric sensor 2 and the piezoelectric actuator 3 described in the second specific embodiment. In this embodiment, it is characterized in that: the piezoelectric sensor 2 and the piezoelectric actuator The electric actuators 3 are piezoelectric sheets. Other compositions and connection methods are the same as those in the second embodiment.

[0024] In this embodiment, the piezoelectric sensor 2 and the piezoelectric actuator 3 use piezoelectric sheets because the piezoelectric sheets will generate voltage when they deform, and the voltage when one of the piezoelectric sheets is deformed will be used as a feedback signal Pass it to the controller 4, and the controller 4 processes the signal into a new voltage and feeds it back to another piezoelectric sheet. The other piezoelectric sheet will change the stiffness according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com