Achromatic prime lens

A fixed-focus lens and achromatic technology, which is applied in the field of fixed-focus lenses, can solve the problems of complex overall structure of the lens and the difficulty of taking into account the imaging quality of the fixed-focus lens, and achieve the effect of improving imaging quality and high degree of restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

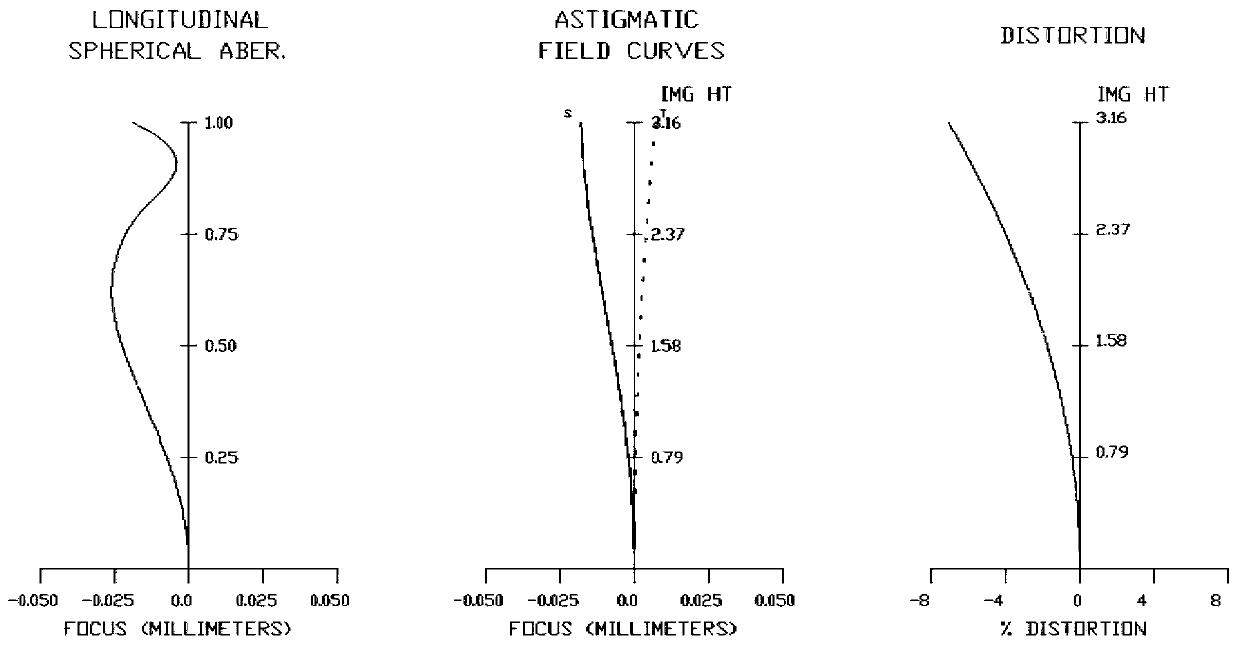

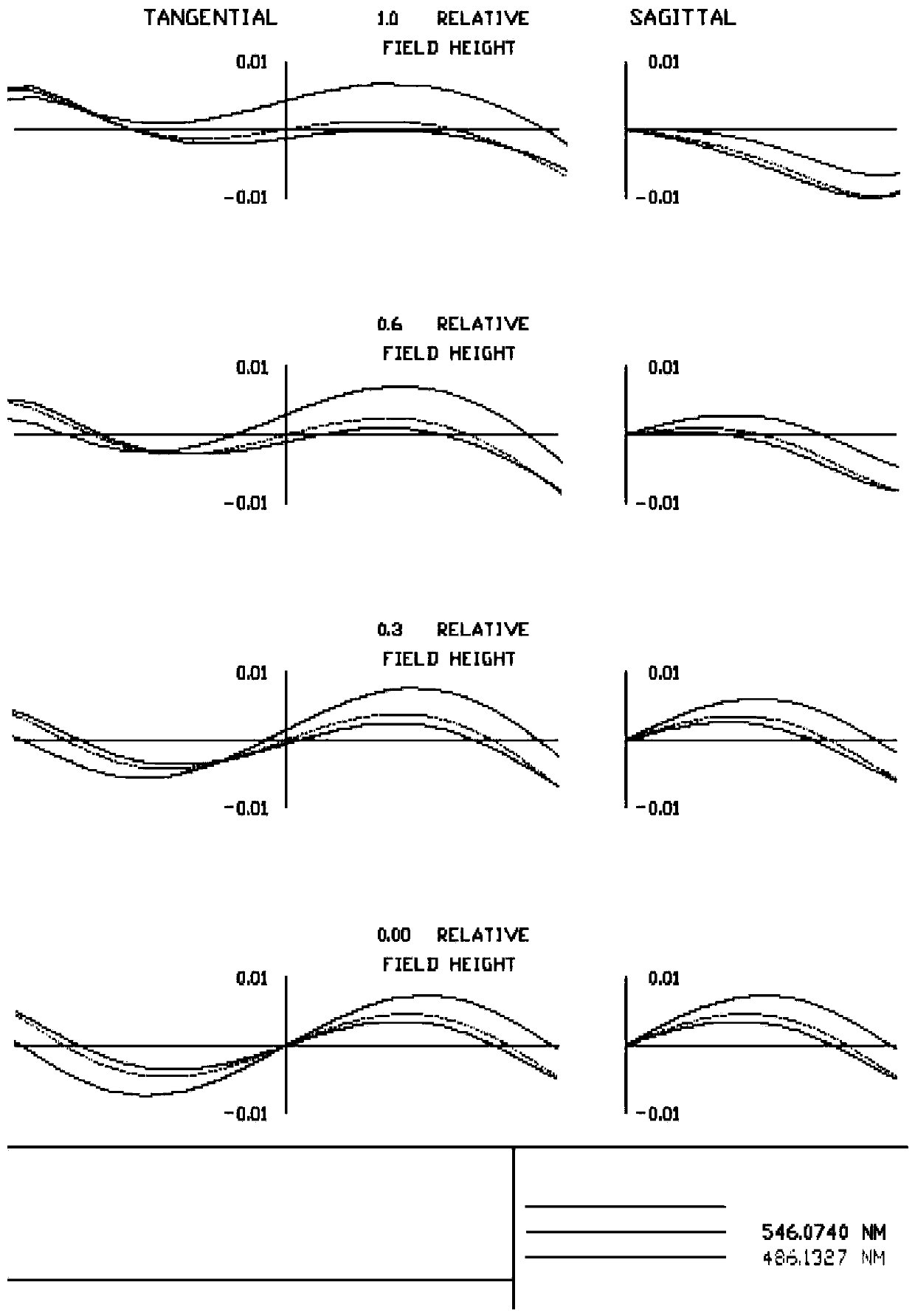

Embodiment 1

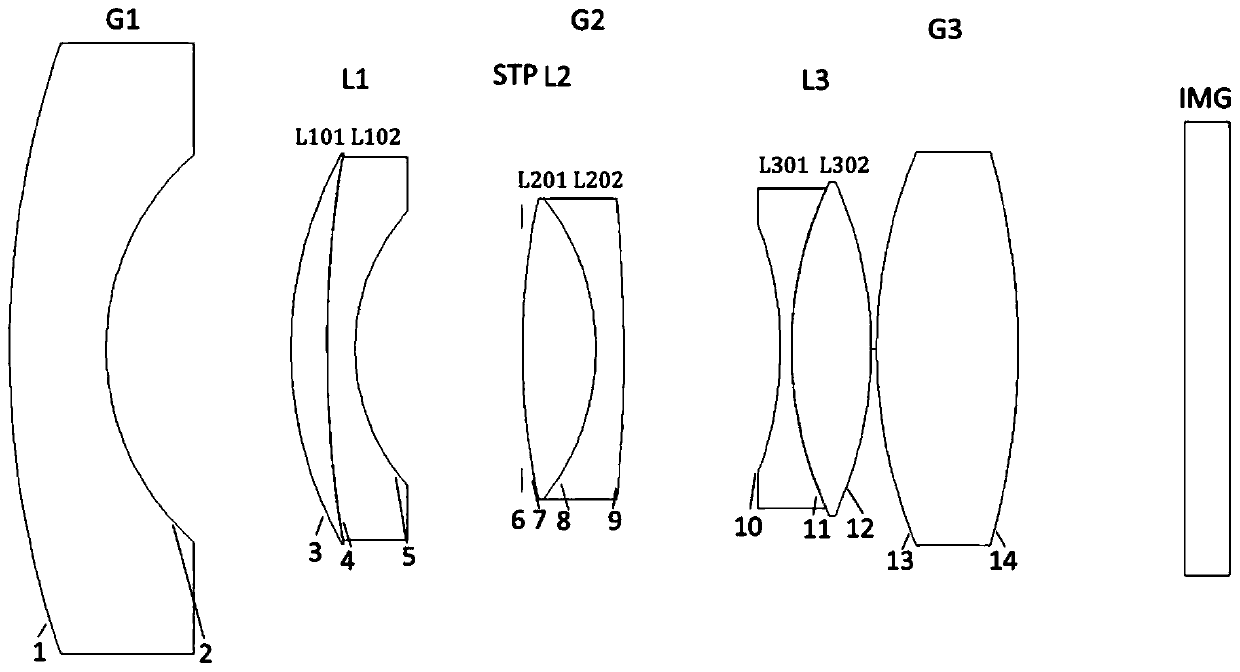

[0025] like figure 1 As shown, in this embodiment, from the object side to the image side, the first lens G1 with negative refractive power, the aperture stop STP, the second lens group G2 with positive refractive power, and the third lens G3 with positive refractive power and an imaging surface IMG with imaging elements.

[0026] The first lens G1 is a glass lens.

[0027] The second lens group G2 includes in order from the object side to the image side: a first cemented lens L1 with negative refractive power and the concave surface of the cemented surface facing the image side, a stop STP, a positive refractive power and the concave surface of the cemented surface facing the object The second cemented lens L2 on the side and the third cemented lens L3 with negative power and the concave surface of the cemented surface facing the image side.

[0028] The first cemented lens L1 is composed of a first pre-cemented lens L1-1 with positive power and a first cemented lens L1-2 w...

Embodiment 2

[0043] like Figure 4 As shown, compared with Embodiment 1, this embodiment adds a fourth cemented lens L4 with negative refractive power and the concave surface of the cemented surface facing the image side after the third cemented lens L3 of the second lens group G2.

[0044] The fourth cemented lens L4 is composed of a fourth pre-glued lens L4-1 with negative power and a fourth cemented lens L4-2 with positive power.

[0045] Both the fourth pre-glued lens L4-1 and the fourth cemented lens L4-2 are glass spherical lenses.

[0046] Various data values of this embodiment are shown below.

[0047] The effective focal length of the lens is EFL=5.9mm, and the numerical aperture is FNO=1.8.

[0048] Table 2 Embodiment 2 Lens Structural Parameters (the units of radius of curvature and thickness are mm)

[0049]

[0050]

[0051] Wherein the image side of the first pre-glued lens L1-1 is the object side of the first cemented lens L1-2, the image side of the second pre-gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com