Waterproof sealing structure for top of columnar object and antenna

A technology of waterproof sealing and pillars, which is applied in the direction of sealed shell, radiating element structure, antenna support/installation device, etc. It can solve the problems of complex demoulding process, increased mold cost, and easy gaps, etc., and achieves good waterproof effect , Low production cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

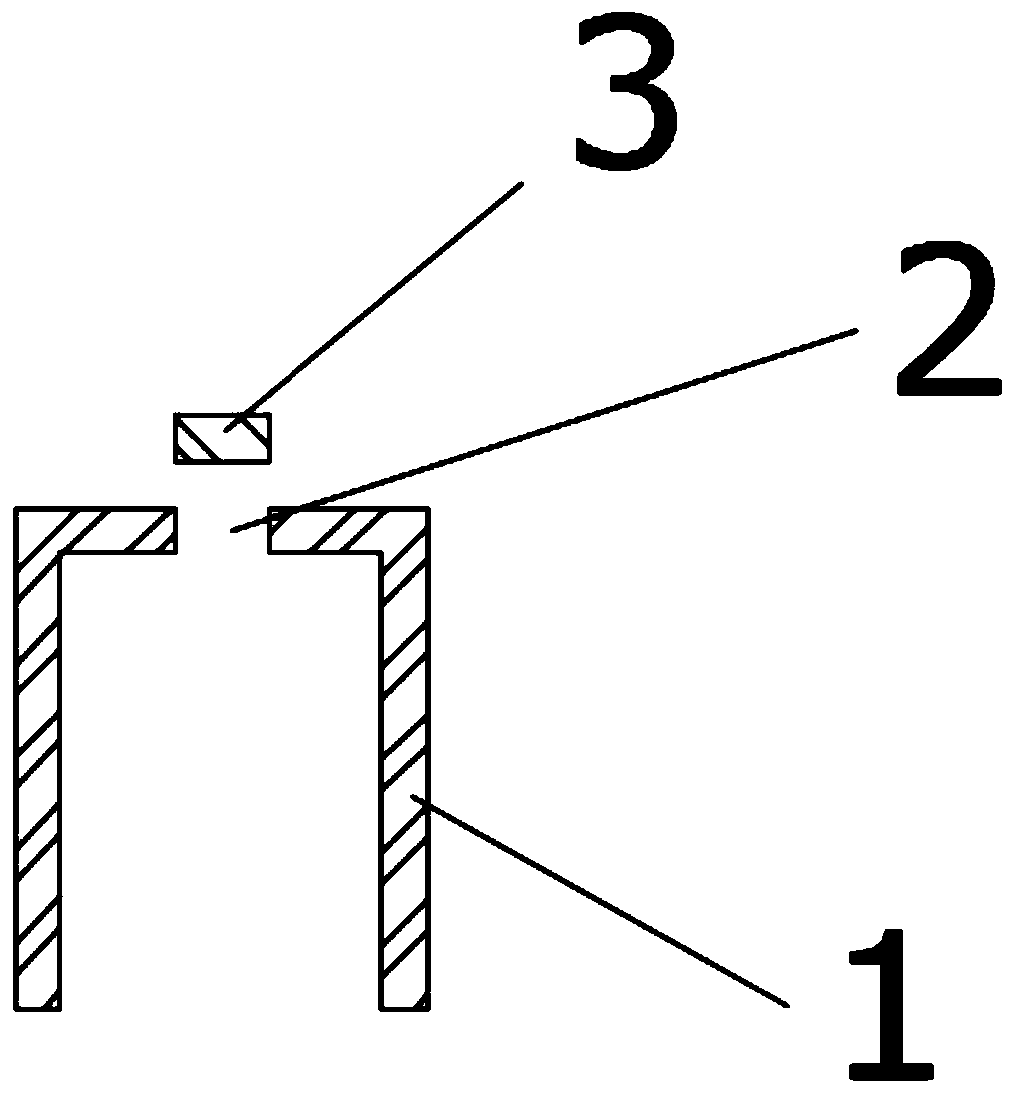

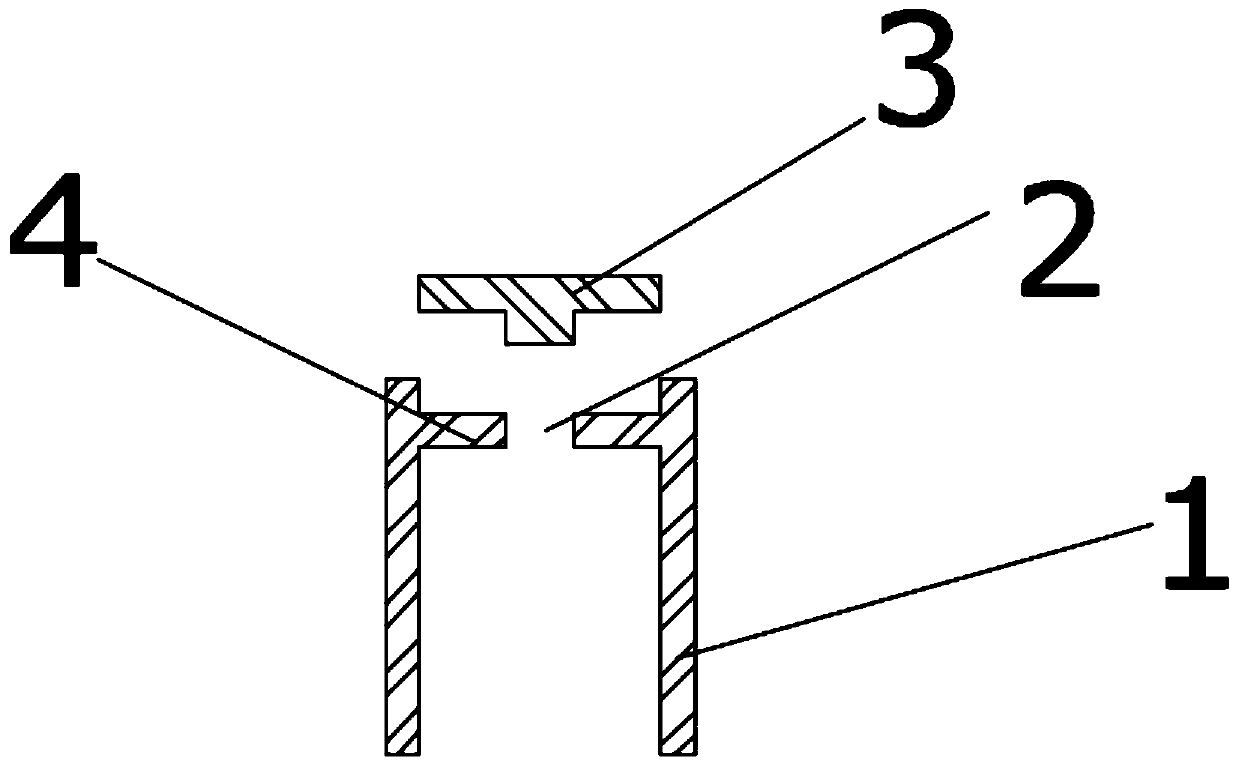

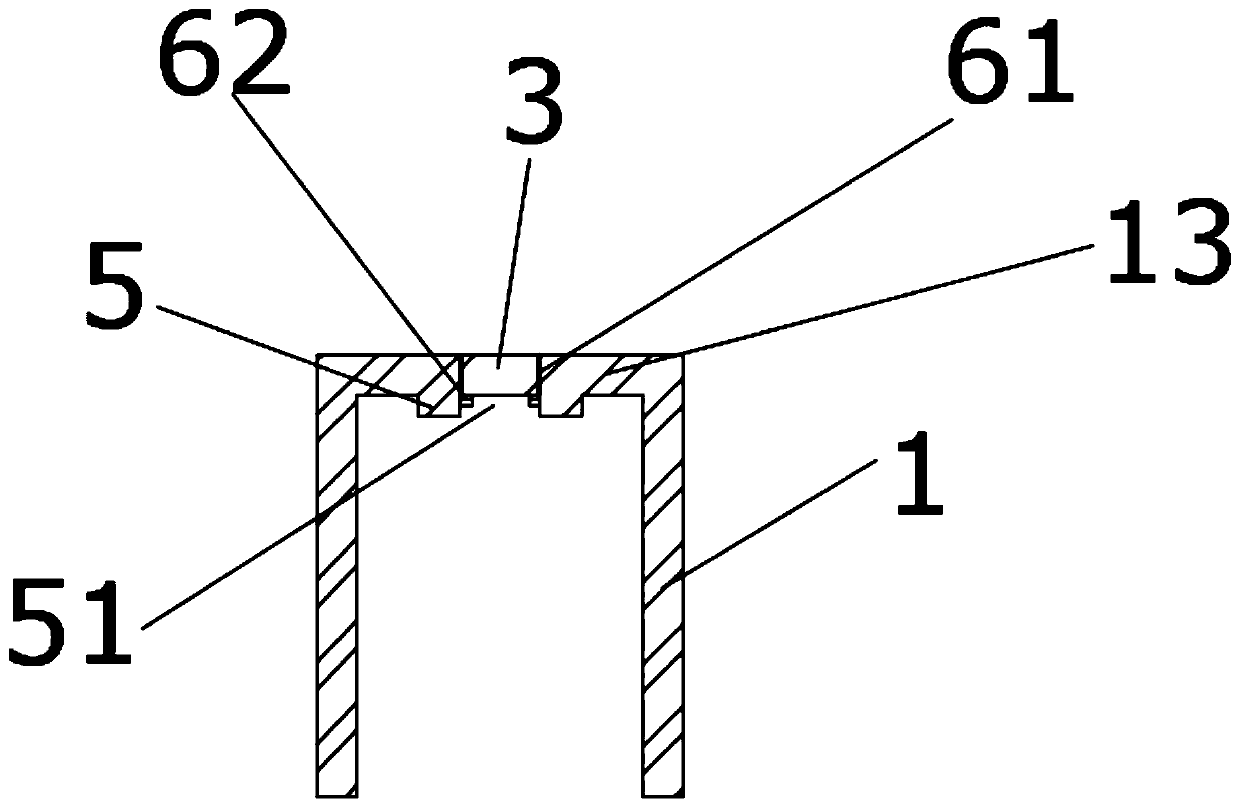

[0039] Such as Figure 3-Figure 6 As shown, the embodiment of the column top waterproof sealing structure disclosed in the present invention includes a housing 1 and a top cover 3, the housing 1 is columnar, the lower end of the housing 1 is open 12, and the upper end of the housing 1 has a sealing surface 13, The center of the sealing surface 13 has an opening 2, the line connecting the center of the opening 2 and the center of the opening 12 coincides with the axis of the housing 1, the top cover 3 is adapted to the opening 2, and the sealing surface 13 protrudes downward from the opening 2 with an extension 5. The extension part 5 can be columnar, cylindrical or polygonal. The extension part 5 can also be in the shape of a truncated cone, which can be a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com