Ground glass manufacturing and processing system

A processing system, frosted glass technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve the problems of high production cost of frosted glass, inability to accurately control frosted glass, etc., to achieve high-quality surface quality, precision The effect of controlling and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

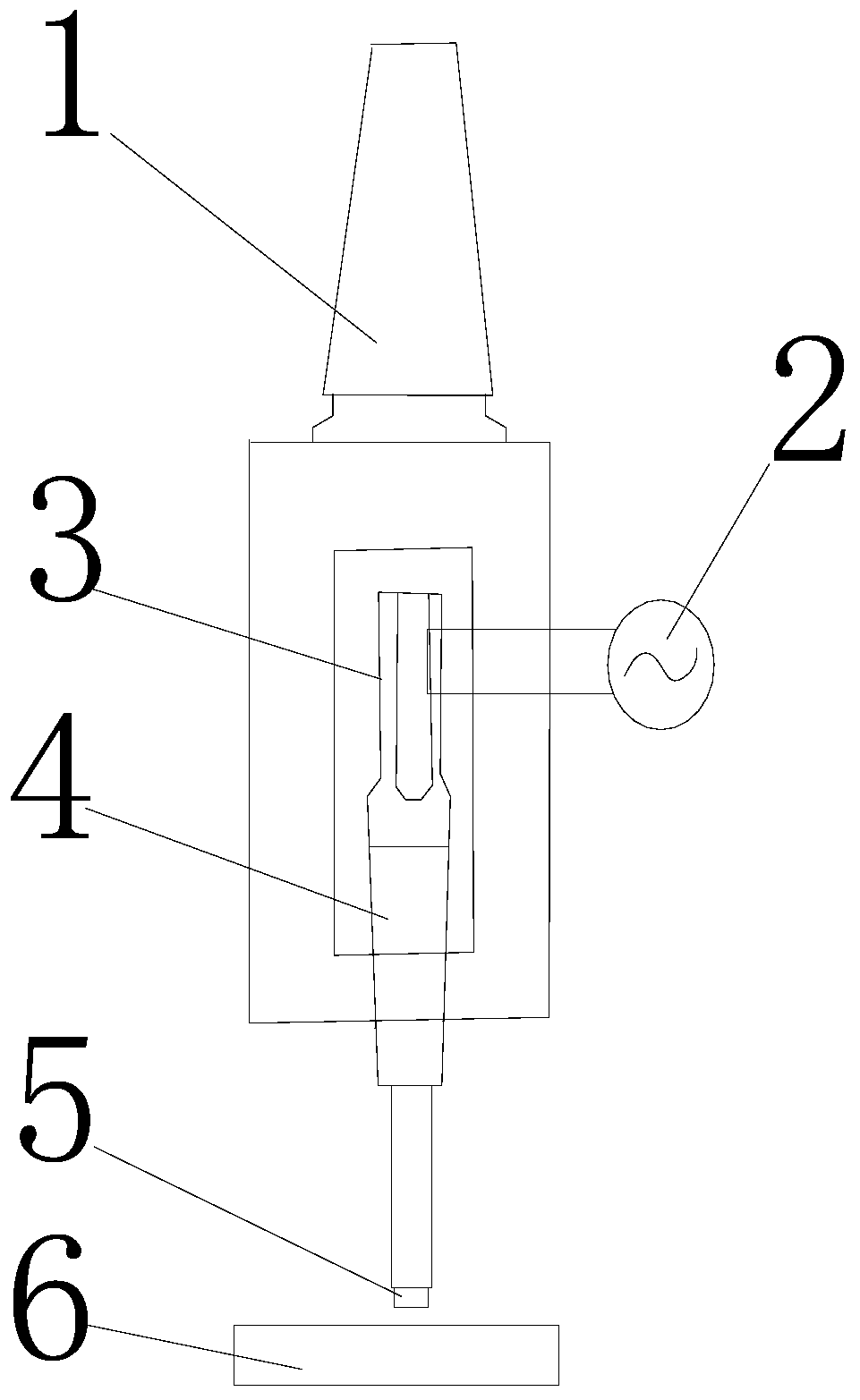

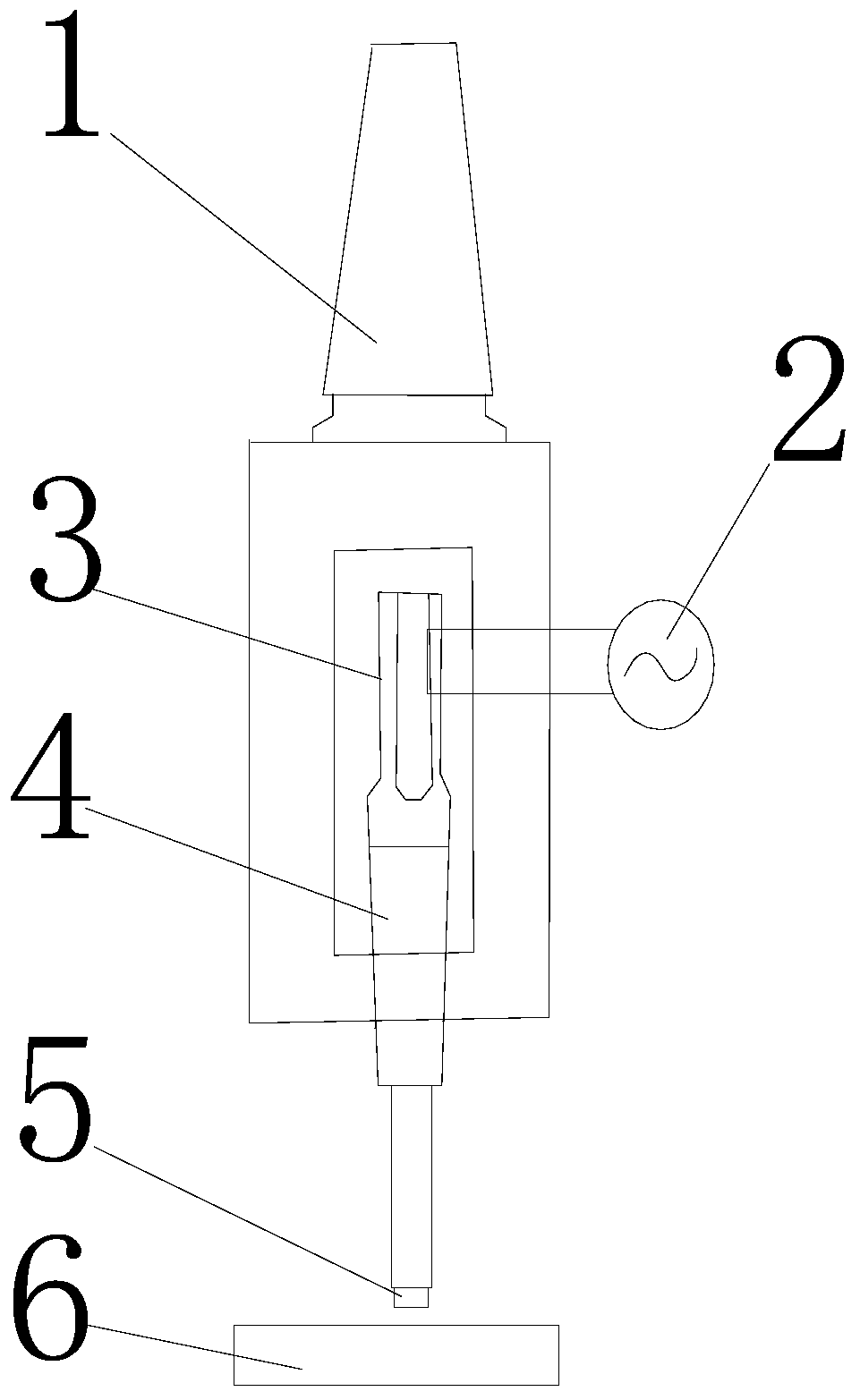

[0015] Examples such as figure 1 As shown, a frosted glass manufacturing and processing system is provided with a processing machine tool with a rotating main shaft 1, a grinding tool 5 fixed on the rotating main shaft 1, and an ultrasonic generator 2 arranged on the processing machine tool, driven by the rotating main shaft 1. The grinding tool 5 is rotated so that the high-frequency vibration generated by the ultrasonic inverse piezoelectric effect is transmitted to the grinding tool of the rotating spindle, so that the grinding tool 5 has a two-way grinding force with vibration and rotation superimposed. The specific processing steps are as follows:

[0016] ① Fix the glass 6 to be processed on the workbench of the machine tool with ultrasonic generator 2;

[0017] ② Adjust the processing parameters such as the rotation speed of the rotating spindle 1, the processing feed rate, and the cutting step distance, as well as the distance between the grinding tool and the processi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap