Car lamp reflecting body with adjusting base

A technology for automotive lamps and reflectors, applied to reflectors, motor vehicles, road vehicles, etc., can solve the problems of high maintenance, easy wear and tear of structures, and affect assembly, so as to reduce mold development costs, reduce maintenance costs, and reduce The effect of producing finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

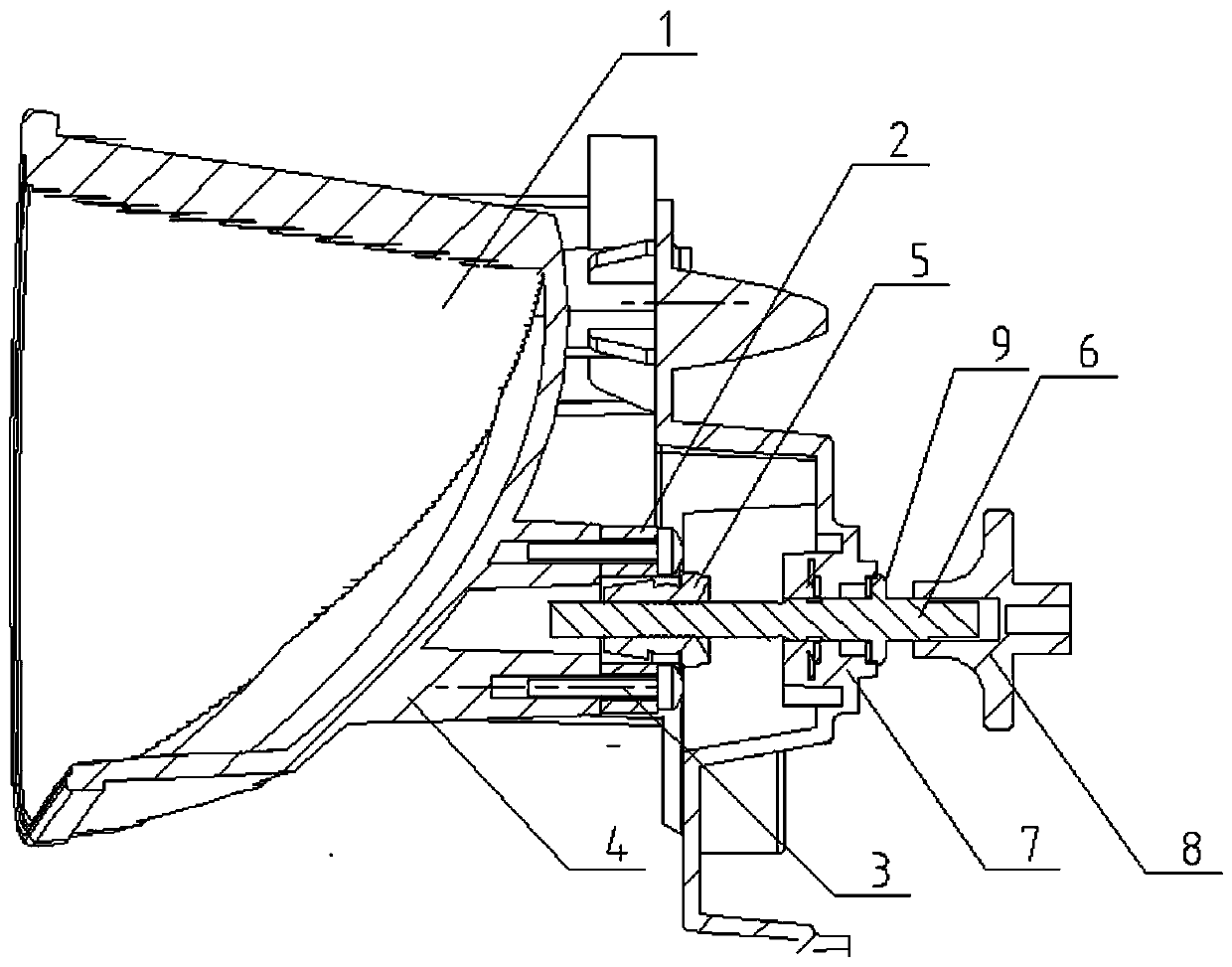

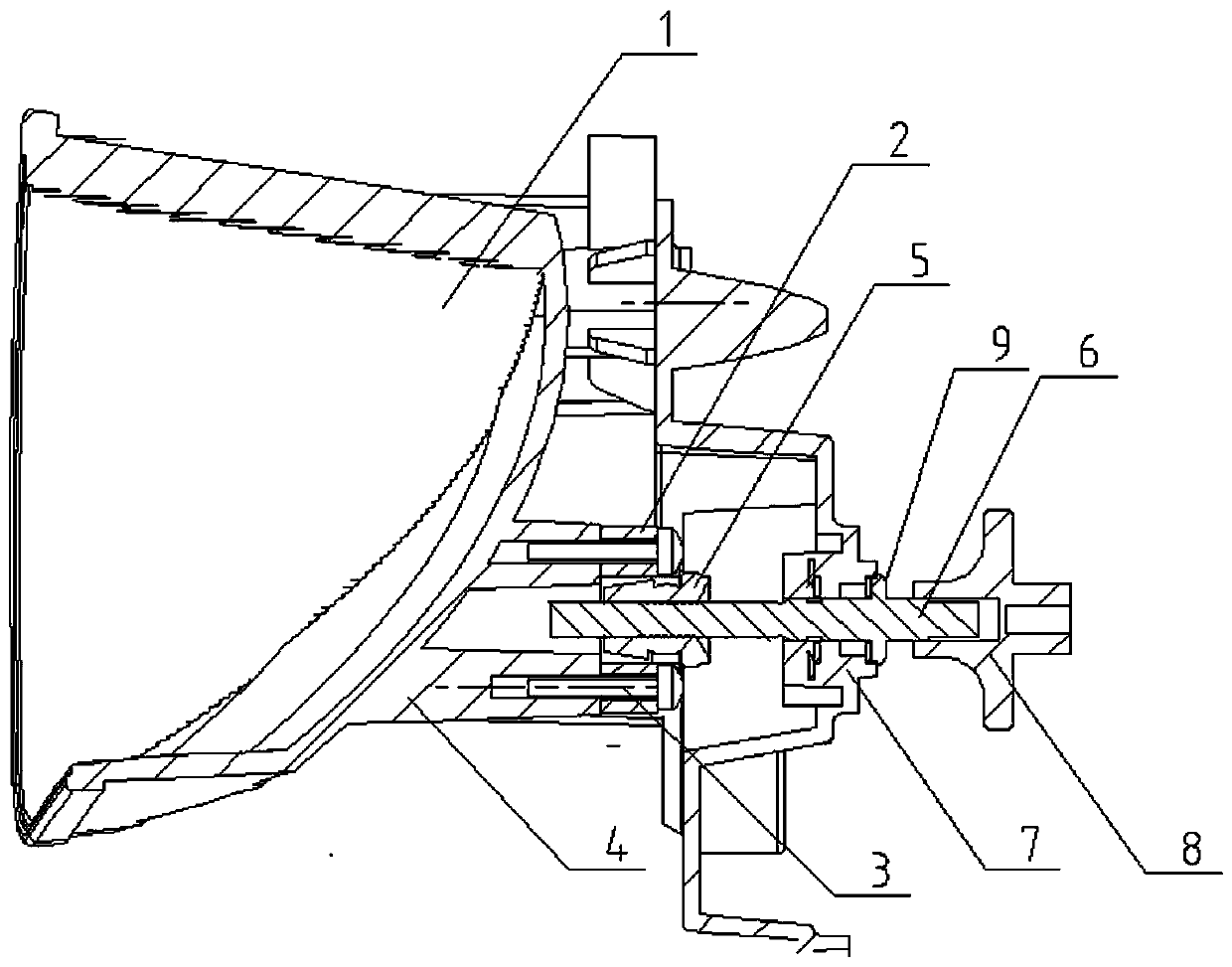

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in the figure, a reflector for automobile lamps with an adjustment seat includes a reflector body 1, an adjustment seat 2 and an adjustment screw 6. The back of the reflector body 1 is provided with two spaced bosses 4, and the bosses 4 The ends are on the same plane, the adjusting seat 2 is respectively fixed by the screw 3 and the two bosses 4, the adjusting nut 5 is fixedly clamped inside the adjusting seat, the axis of the adjusting nut is located between the two bosses 4, the adjusting screw 6 is connected and Supported on the lamp housing 7, one end of the adjusting screw 6 is screwed and matched with the adjusting nut 5, and the matching end can extend parallelly into the space between the two protrusions 4, and the other end of the adjusting screw 6 is equipped with a hand wheel 8, and the adjusting screw is provided with a limit position Boss 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com