Device for detecting erosion corrosion of reducing pipe and detection method thereof

A technology for erosion corrosion and reducer pipes, which is applied in the field of erosion corrosion detection devices, can solve the problems that the erosion corrosion characteristics of reducer pipes and the interaction between erosion and corrosion cannot be characterized, and there are few researches on erosion corrosion of reducer pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

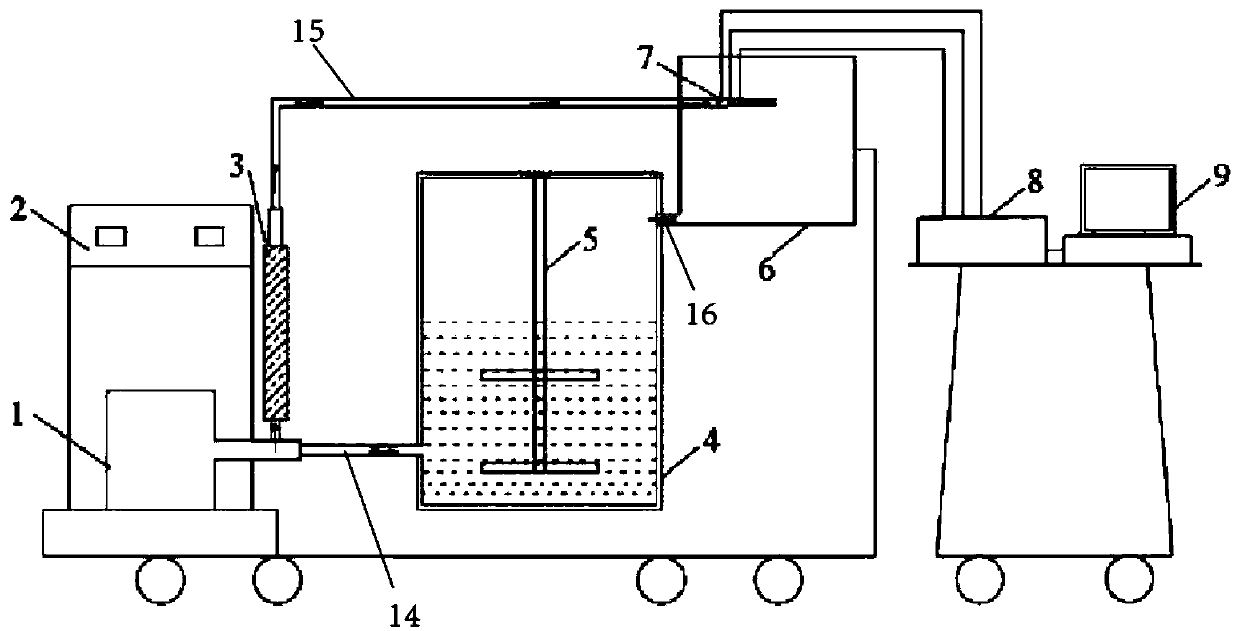

[0034] A device for detecting erosion corrosion of a reducer, comprising a test device and a reducer portion,

[0035] The test device includes a screw pump 1, a control cabinet 2, a water tank 4, a flushing chamber 6 and an electrochemical test recording device. The water outlets are connected, and the water outlet of the screw pump 1 is connected with the water inlet of the flushing chamber 6 through the flushing water inlet pipeline 15, and the water outlet of the flushing chamber 6 is connected with the water inlet of the water tank 4 through the flushing water outlet pipeline 16. The pipe part is installed in the flushing chamber 6, and the reducing pipe part is connected with the flushing water inlet pipeline 15, and the electrochemical test recording device is connected with the reducing pipe part through the test wire;

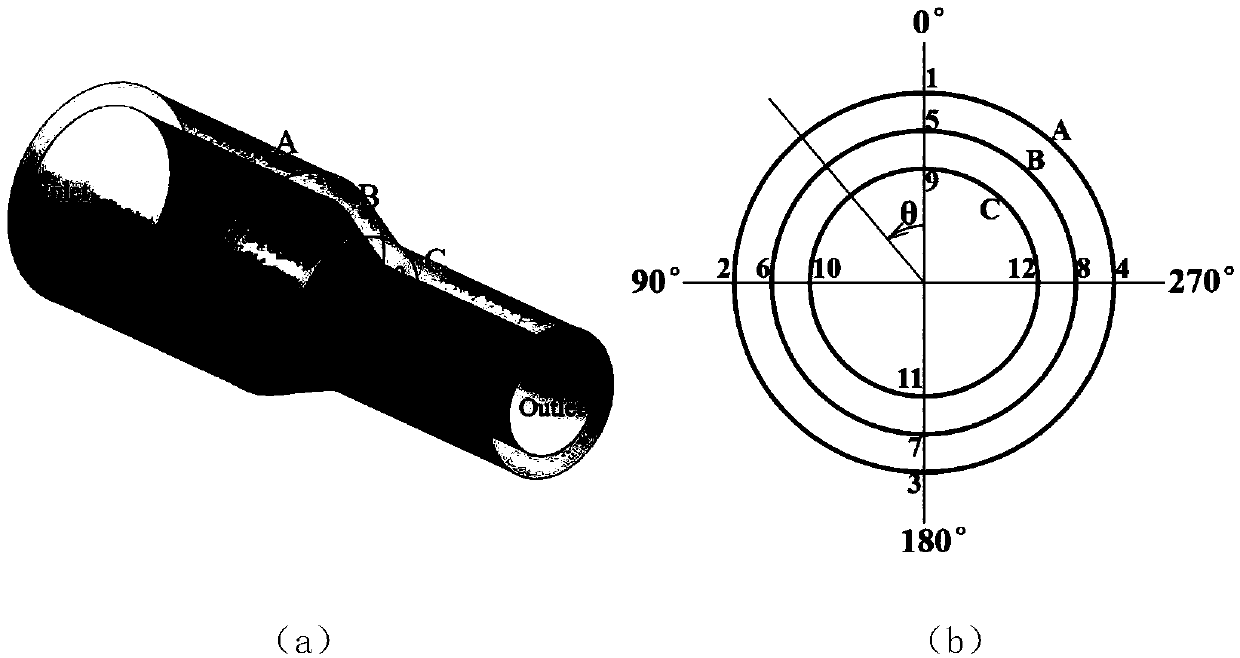

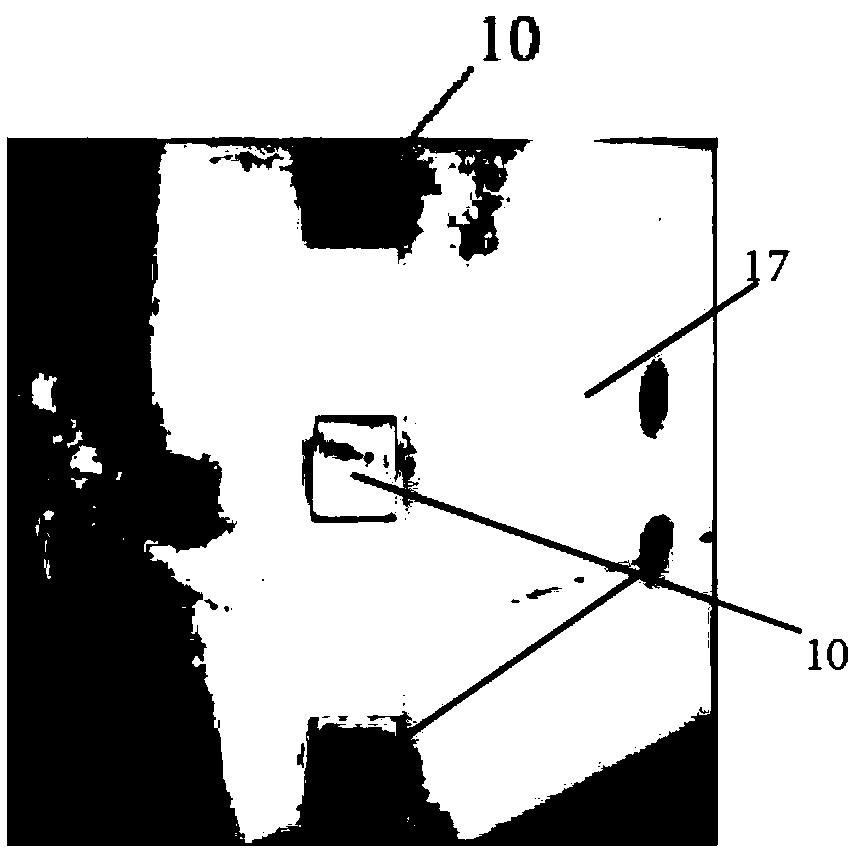

[0036]The reducer part comprises a reducer mold 17, a large end groove, a variable diameter groove, a small end groove and a connector 13, and a large...

Embodiment 2

[0039] On the basis of Embodiment 1, the number of different-diameter tube molds 17 is 4, 6 or 8, the surface of the working electrode 10 is flush with the inner surface of the pipe diameter of the different-diameter tube mold 17, and the working electrode 10 is encapsulated by epoxy resin In the large end groove, the variable diameter groove and the small end groove of the reducing pipe mold 17.

Embodiment 3

[0041] On the basis of Embodiment 2, the screw pump 1 adopts an adjustable screw pump, which can adjust the flow rate of the medium in the control pipeline. A flow meter 3 is provided on the flushing water inlet pipeline 15, and a flow meter 3 is also provided in the water tank 4. The solution is mixed homogeneously with a blender 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com