Fatigue loading device for in-situ observation of scanning electron microscope

An electron microscope, fatigue loading technology, applied in measurement devices, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., can solve problems such as failure to achieve fatigue loading, and improve experimental stability and data reliability The effect of stability, small and compact structure design, ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

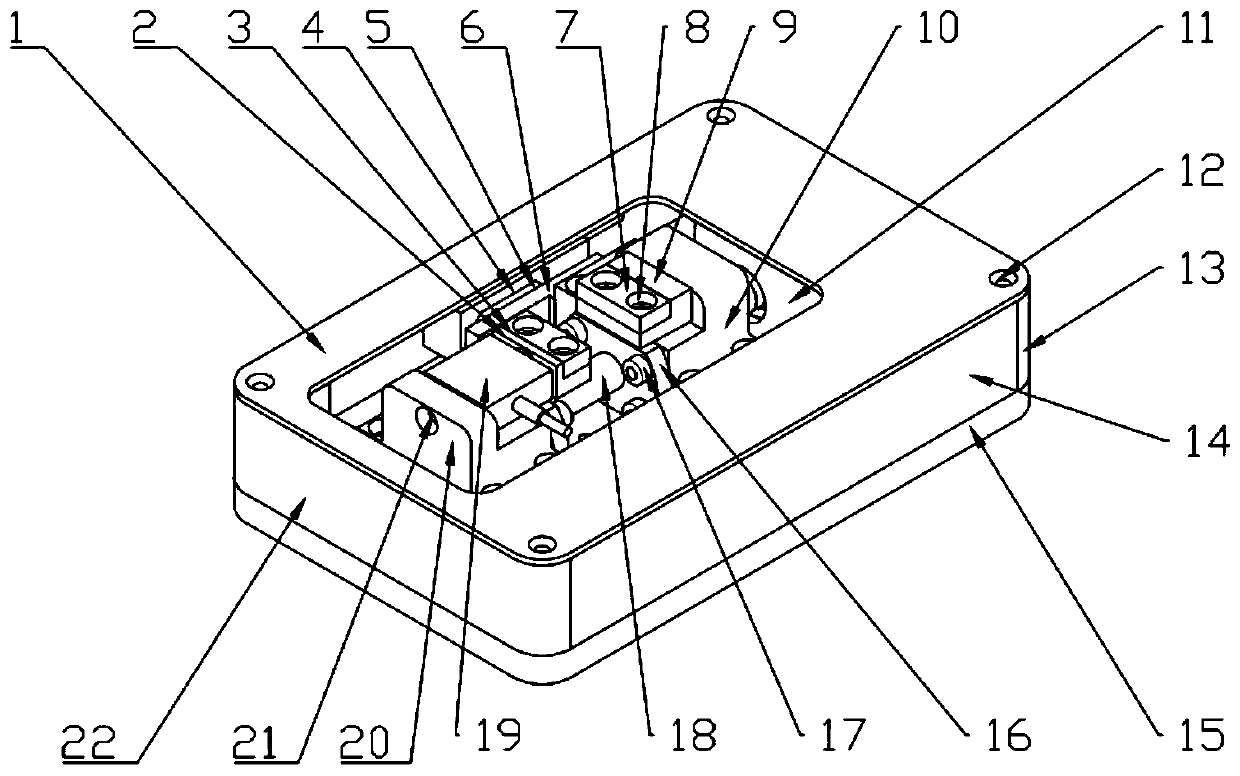

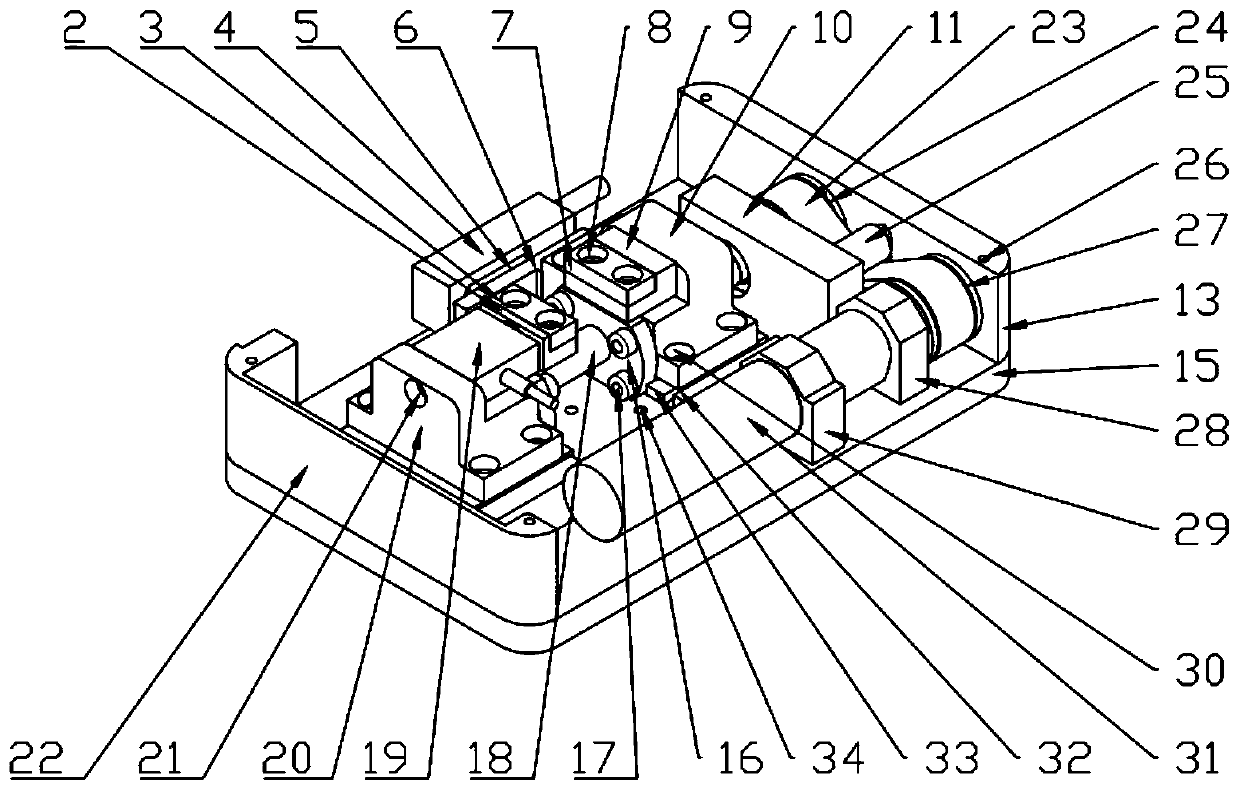

[0027] like figure 1 and figure 2 As shown, this embodiment provides a fatigue loading device for in-situ observation by a scanning electron microscope, which is mainly composed of a structure, a mechanical loading unit, a data acquisition unit, a fixed connection unit and a sealed connection unit.

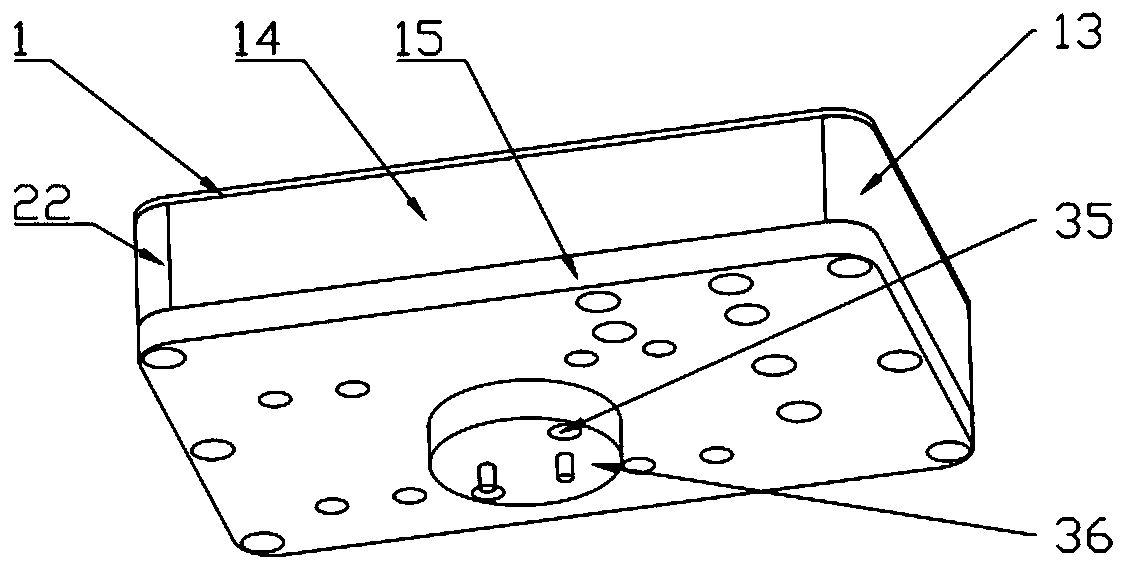

[0028] The structural body includes an outer cover plate, a middle support plate 11 , a pulley fixing block 28 and a motor fixing block 29 . The mechanical loading unit and the data acquisition unit are arranged inside the outer cover plate, and the outer cover plate mainly plays a shielding role. The outer cover consists of an upper cover plate 1 at the top, a base plate 15 at the bottom, side cover plates 14 at both sides, first support plates 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com