Safe automatic grabbing tool for stamping parts

A safe, stamping technology, applied in the directions of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of inability to clamp stamping parts of different lengths, unable to ensure the stability of stamping parts, and inability to adjust the grasping position, etc. It is safe and convenient to use, fits tightly, and avoids falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

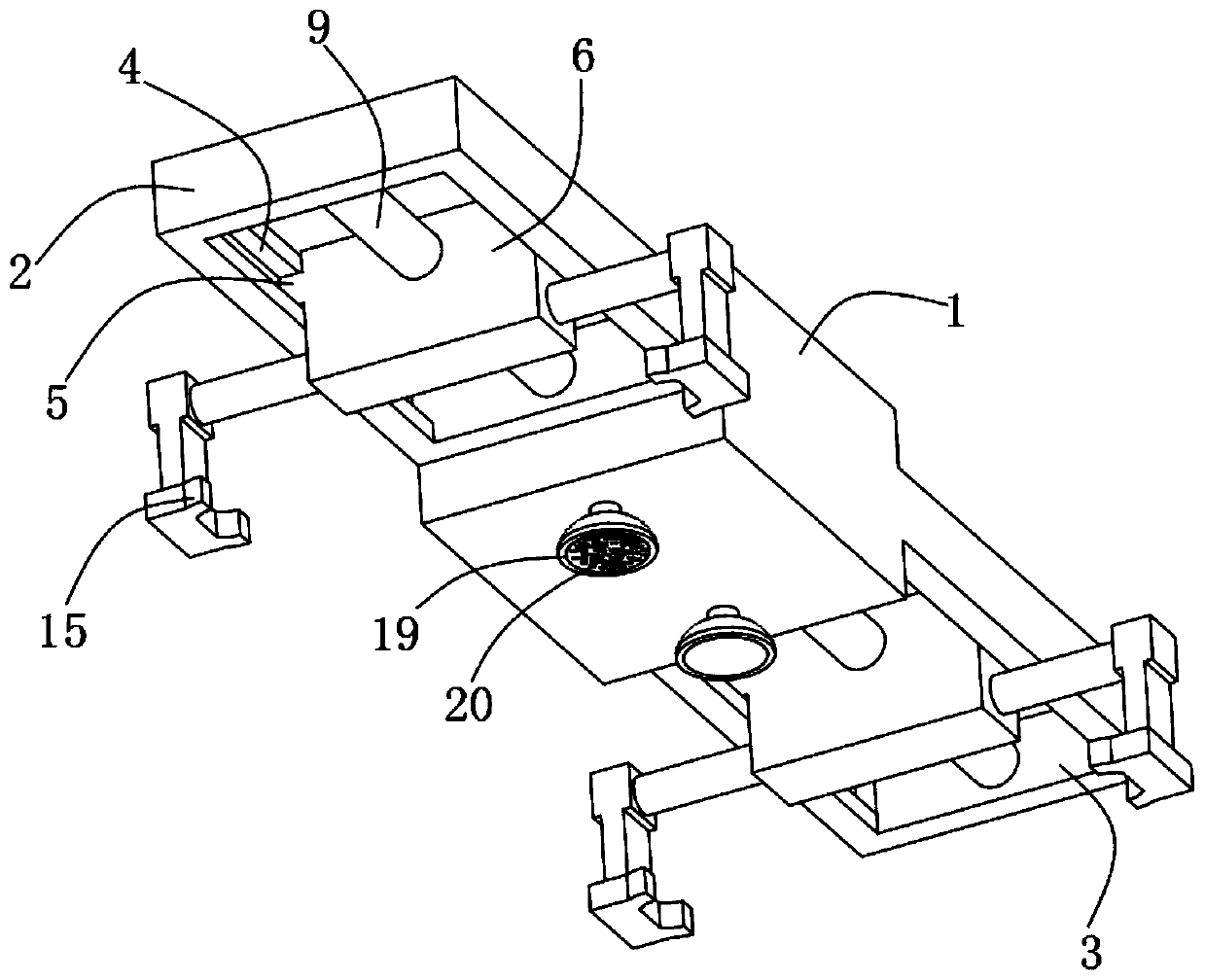

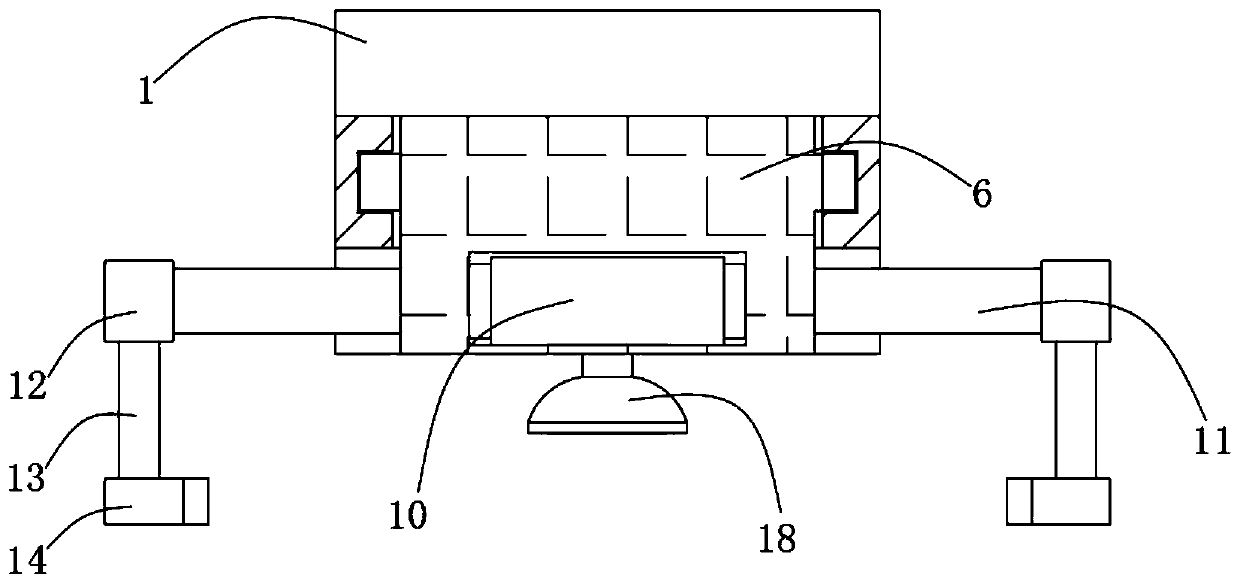

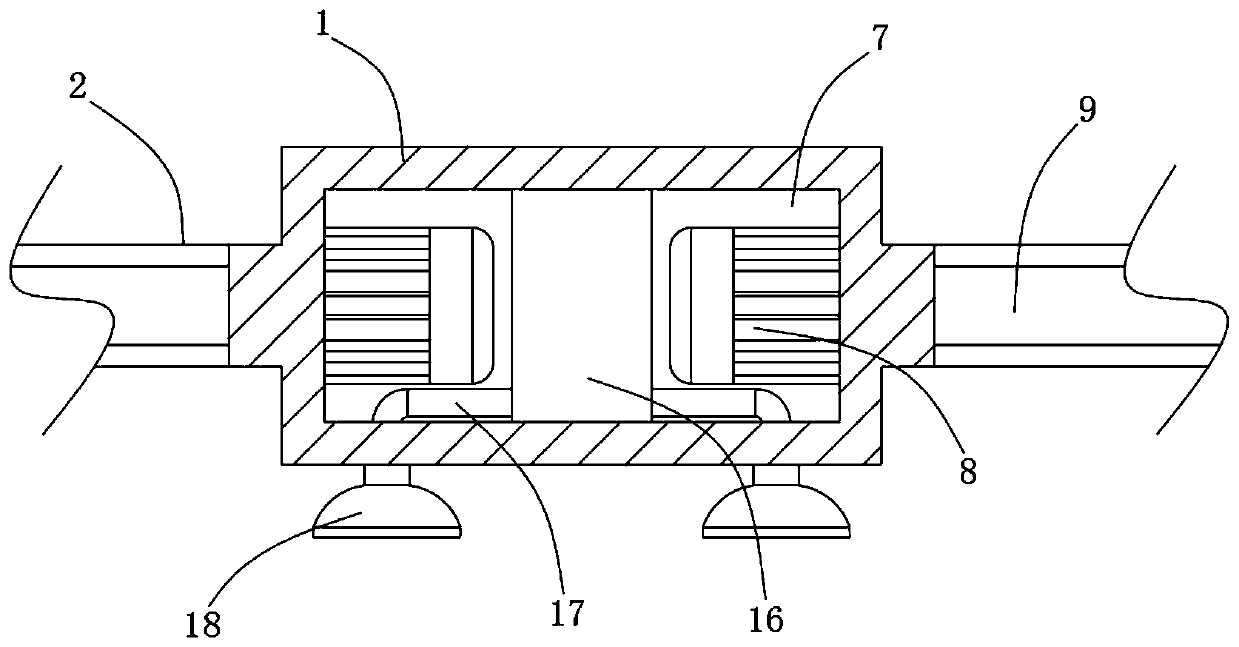

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a safe automatic grabbing tool for stamping parts, including a connecting seat 1, the two ends of the connecting seat 1 are symmetrically fixedly connected to the support frame 2, and the top ends of the two support frames 2 are provided with Groove 3, and the groove 3 runs through the bottom end of the support frame 2, the interior of the groove 3 is symmetrically provided with a chute 4, the inside of the two chute 4 is slidably connected with a slider 5, and the adjacent ends of the two sliders 5 are fixed A sliding seat 6 is connected, and a chamber 7 is opened inside the connecting seat 1, and a driving motor 8 is symmetrically and fixedly installed inside the chamber 7, and the input end of the driving motor 8 is electrically connected to the output end of the external power supply, and the two driving motors 8 The output shafts are all fixedly connected with screw rods 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com