Exchangeable tip drill

A kind of drill bit and cutter head technology, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., and can solve the problem of complex stop structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

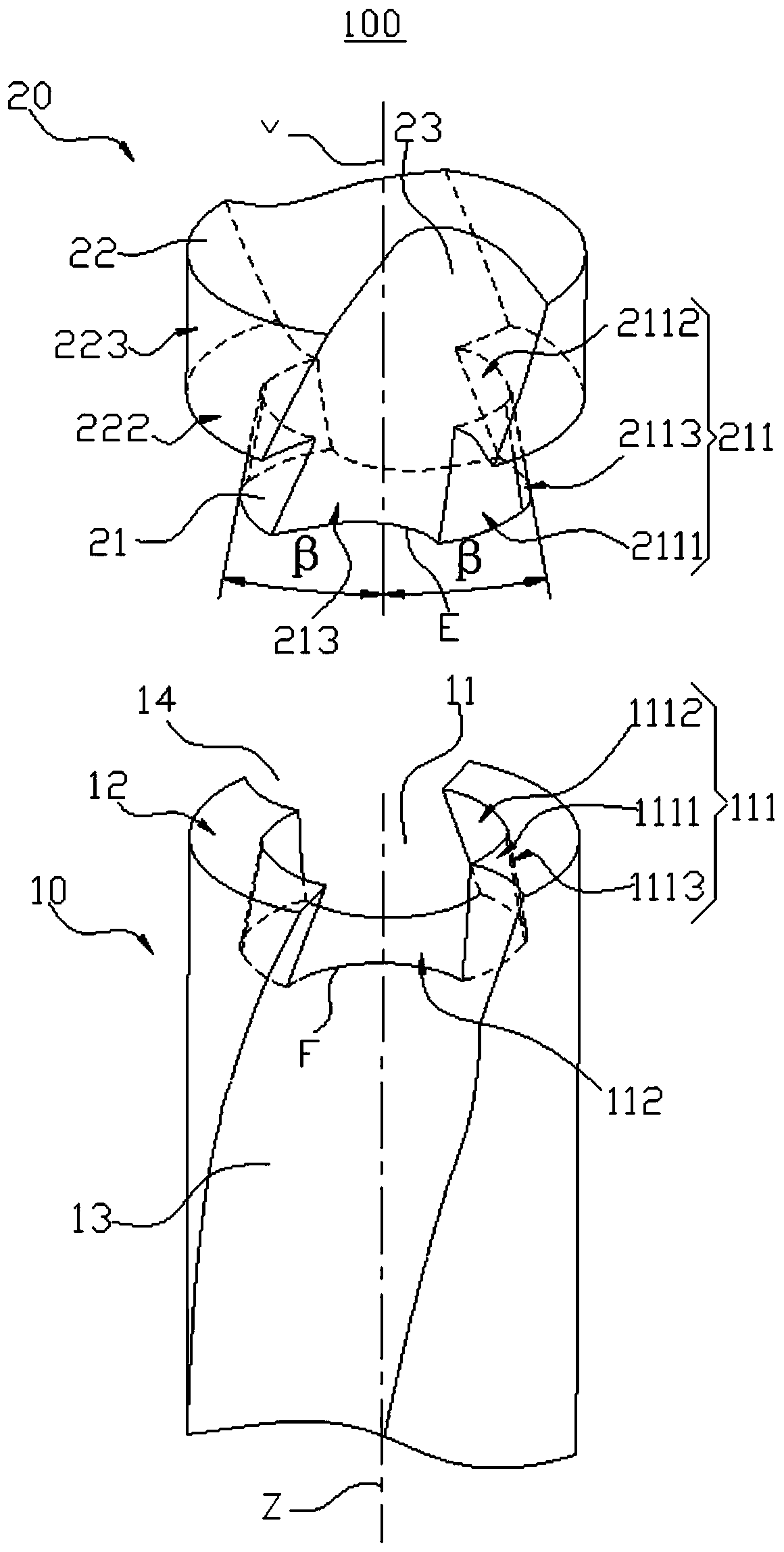

[0061] The embodiment of the present application provides an exchangeable head drill 100, which can realize the stop rotation of the cutter head 20 through a simple structure, which can effectively increase the torque transmission capacity between the cutter bar 10 and the cutter head 20, and can realize centering stably, conveniently and quickly Load and unload the cutter head 20.

[0062] Such as figure 1 As shown, an exchangeable head drill 100 includes a cutter bar 10 and a cutter head 20 . The end of the knife rod 10 is provided with a limiting groove 11 . The cutter head 20 has a docking portion 21 for coaxially arranging the cutter head 20 and the cutter bar 10 after being matched with the limiting groove 11 . The inner peripheral wall of the limiting groove 11 matches the outer peripheral wall of the docking portion 21 .

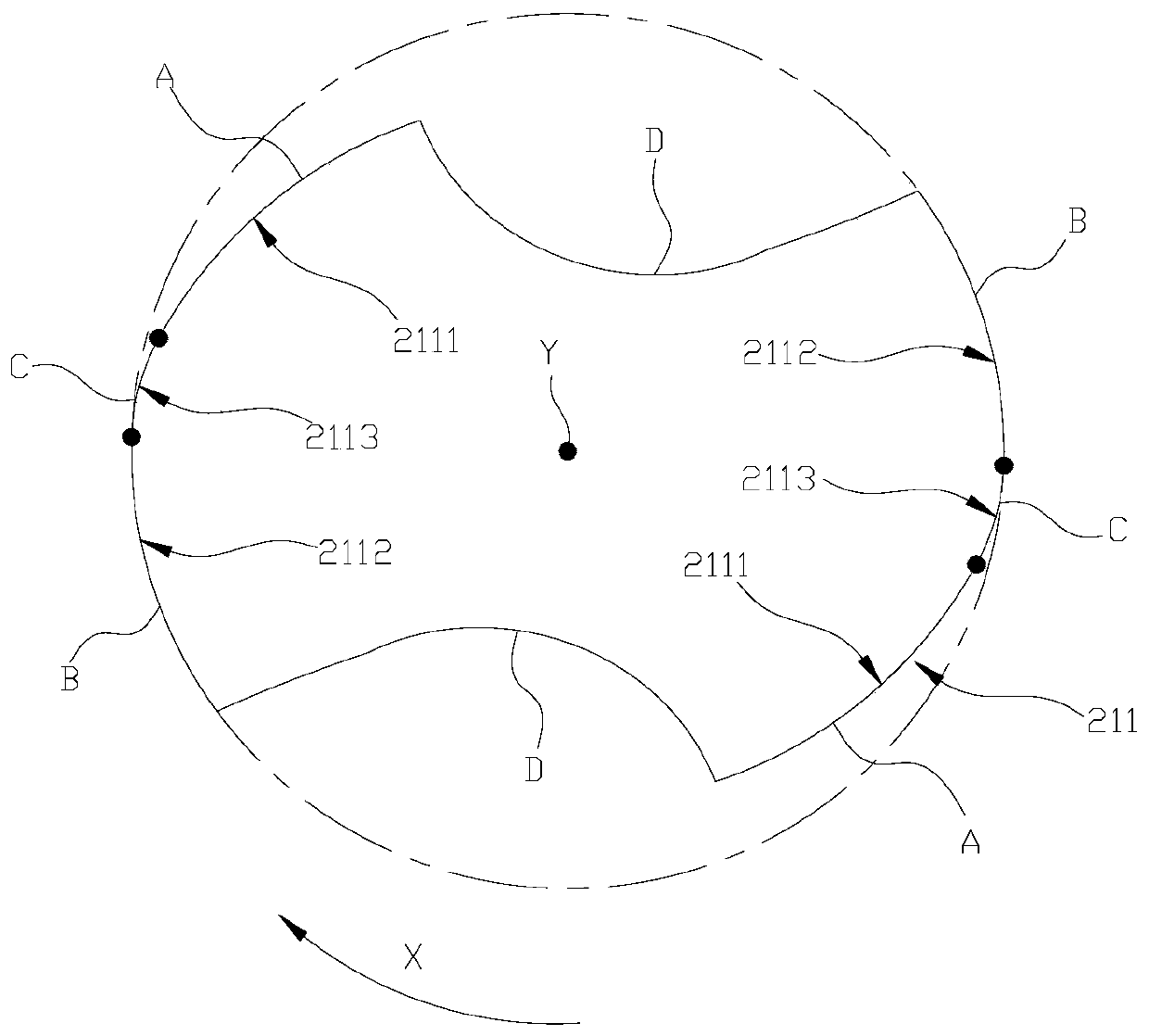

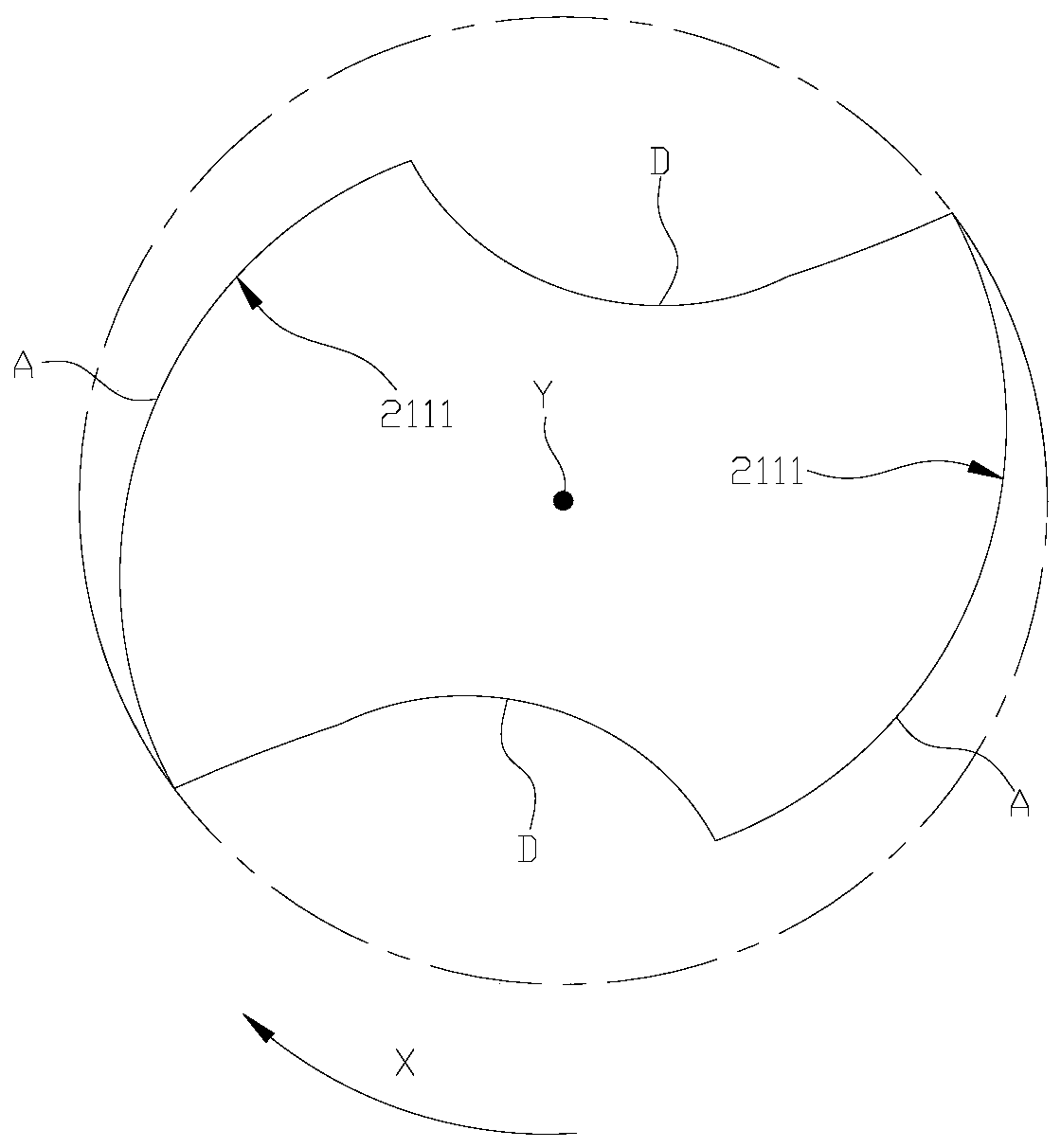

[0063] Wherein, the peripheral wall of the docking portion 21 includes a first curved surface 211 , and the first curved surface 211 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com