Combined asynchronous construction hanging basket

A combined and asynchronous technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of inconvenient installation, inconvenient cost reduction, inconvenient improvement of work efficiency, etc., and achieve the effect of saving costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

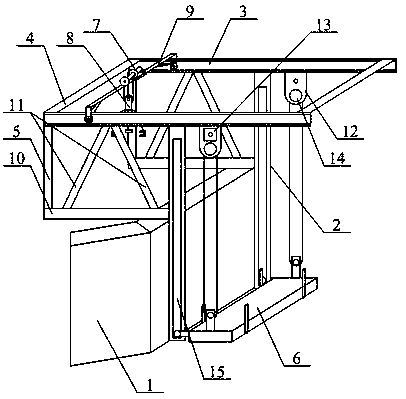

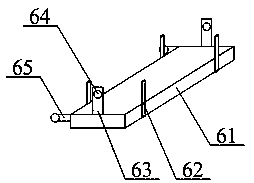

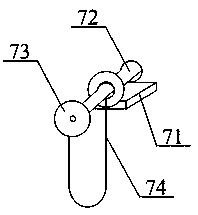

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a combined asynchronous construction hanging basket includes a construction surface 1, a support column 2, a horizontal support track 3, a longitudinal support beam surface 4, and a support rod 5, which can block the lifting seat structure 6 and can fix the winding seat structure 7 , can be articulated with the adsorption protection seat structure 8, the slidable support frame structure 9, the fixed rod 10, the diagonal strut 11, the hoisting seat 12, the power drive device 13, the lifting device 14 and the sliding hole 15, the support column 2 The upper ends are respectively bolted to the middle of the lower end of the transverse support track 3; the longitudinal support beam surfaces 4 are respectively bolted to the left and right sides of the upper end of the transverse support track 3; the upper ends of the support rods 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com