Chemical risk monitoring method based on principal component analysis

A principal component analysis, risk monitoring technology, applied in electrical testing/monitoring, testing/monitoring control systems, program control, etc., can solve chemical risks and faults. Accurate and effective diagnosis is very large, and cannot achieve accurate and effective chemical risks and faults. Diagnosis, early warning, difficulty and other problems, to reduce the time for troubleshooting risk failures, improve the ability to assist decision-making, and eliminate noise interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

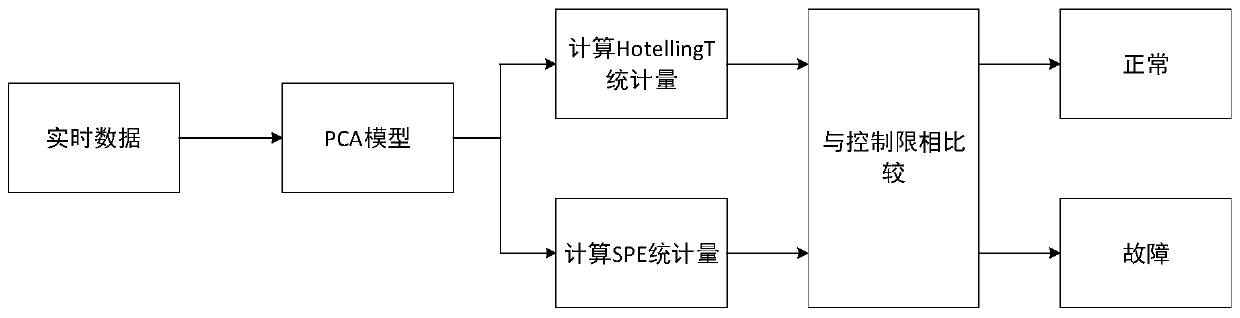

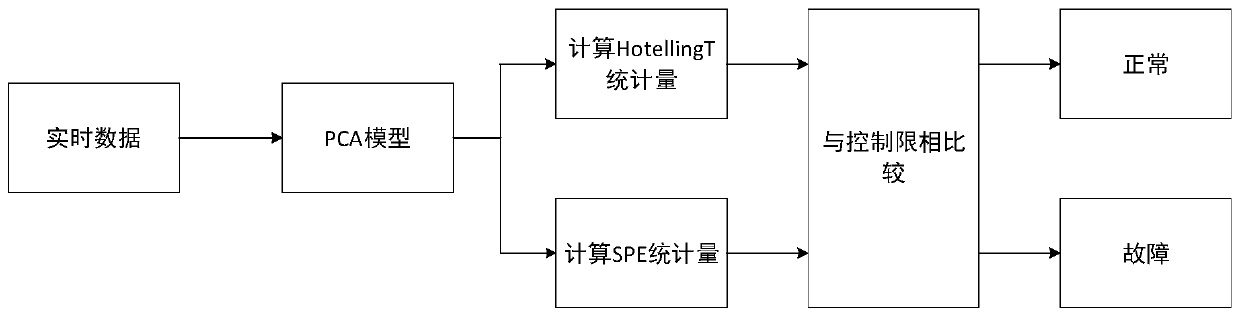

[0020] Such as figure 1 and figure 2 As shown, a chemical risk monitoring method based on principal component analysis is divided into two steps: offline part and online part, which analyze sample data and real-time data respectively. The offline part establishes a principal component analysis algorithm model based on normal data samples, and the online part uses the established model to conduct online chemical risk analysis on real-time data.

[0021] Step 1: Establish principal component analysis algorithm model (offline part):

[0022] 1-1. Obtain m samples of n sensors by sampling to form an X∈R m×n matrix;

[0023] 1-2. Standardize the data;

[0024] 1-3. Perform eigenvalue decomposition on the covariance matrix of X to obtain eigenvalues of different sizes and corresponding eigenvectors;

[0025] 1-4. Arrange according to the size of the eigenvalues to obtain the load matrix P (composed of eigenvectors) and the score matrix T (principal variable);

[0026] Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com