An aerated brick edge leather cutting system

A cutting system and technology of aerated bricks, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of difficult cutting device cutting position adjustment, low limitations, and inability to cut out aerated brick embryos, etc. To achieve the effect of improving cutting accuracy and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

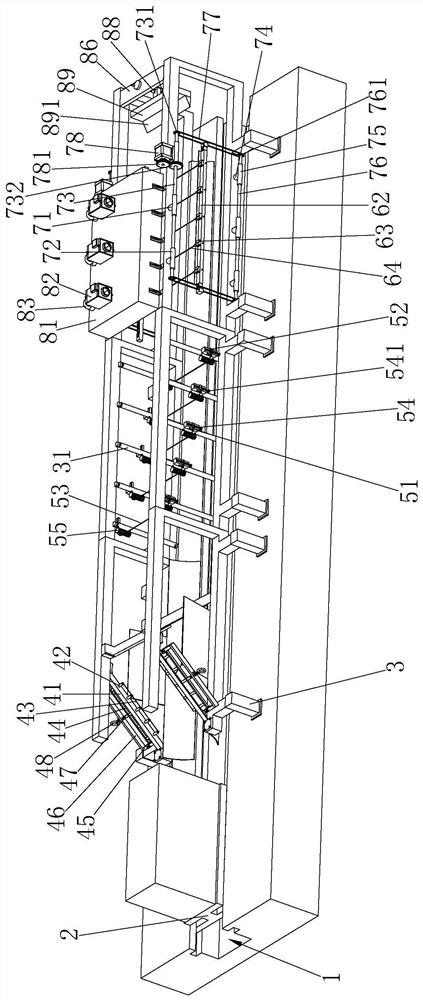

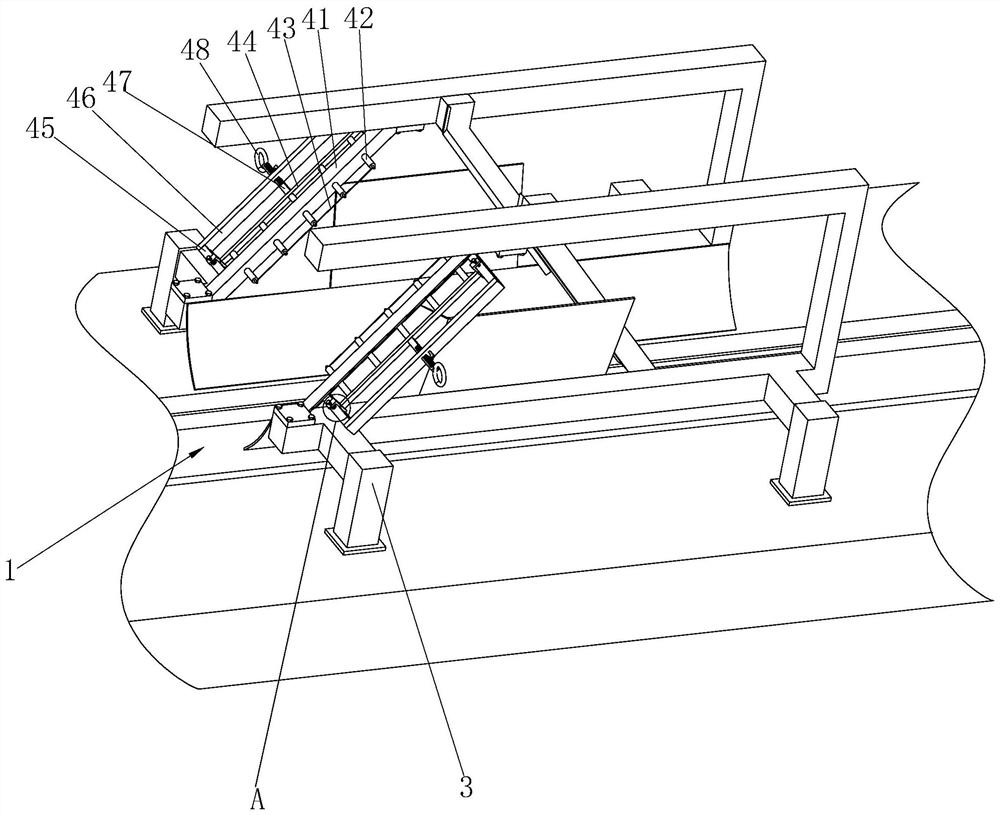

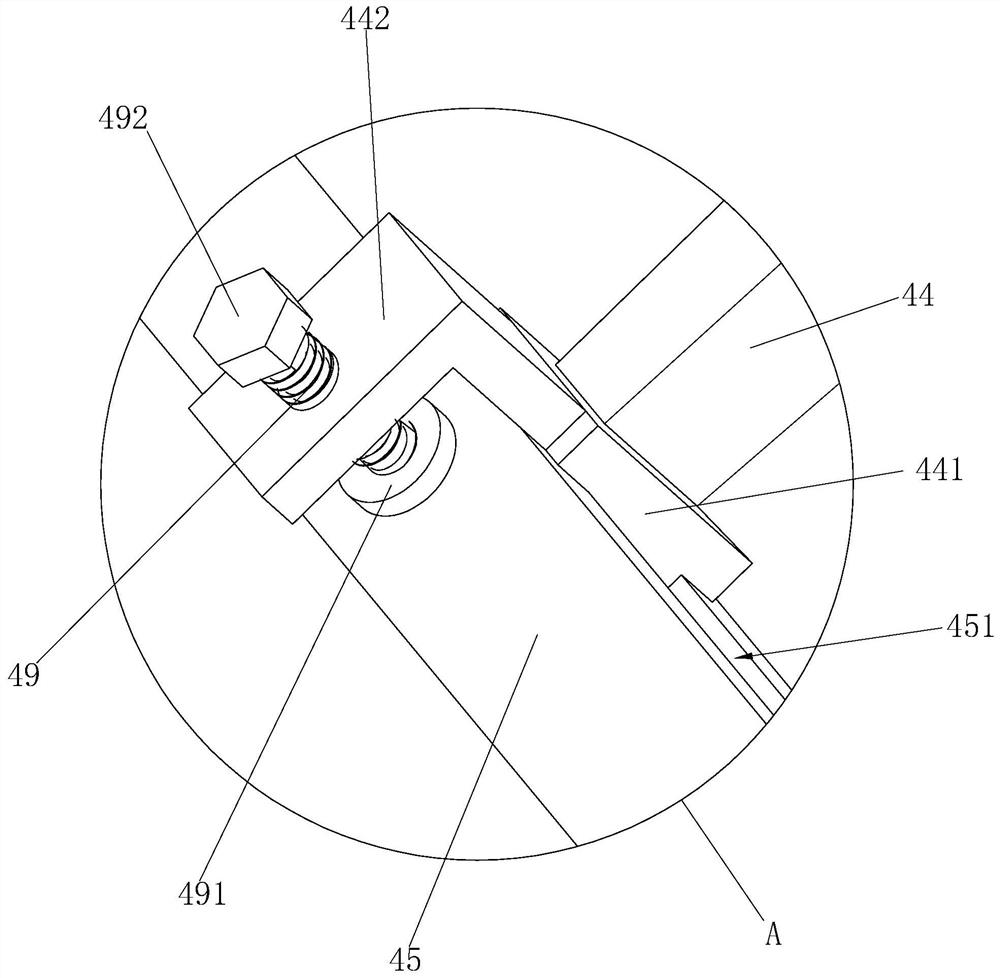

[0044] Such as figure 1 As shown, it is an aerated brick trim material cutting system disclosed in the present invention, including: a groove 1, which is used to uniformly recycle the trim material of the aerated brick; and in the groove 1 A transport trolley 2 is slidably connected inside, and the transport trolley 2 is used to transport the aerated brick blanks to be cut, and a bearing seat 3 is symmetrically fixed on both sides of the groove 1, and the bearing seat 3 is stainless steel It is made of solid material, so it has the advantages of strong support, corrosion resistance and oxidation resistance, which greatly improves the service life of the bearing seat 3; at the same time, a cutting system is set on the bearing base 3, and the cutting system is used for aerated bricks. Brick embryos are cut to produce block-shaped aerated brick products of pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com