Plastic bag heat sealing device

A heat-sealing device and technology for plastic bags, applied in the field of heat-sealing of plastic bags, can solve problems such as low efficiency and waste of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

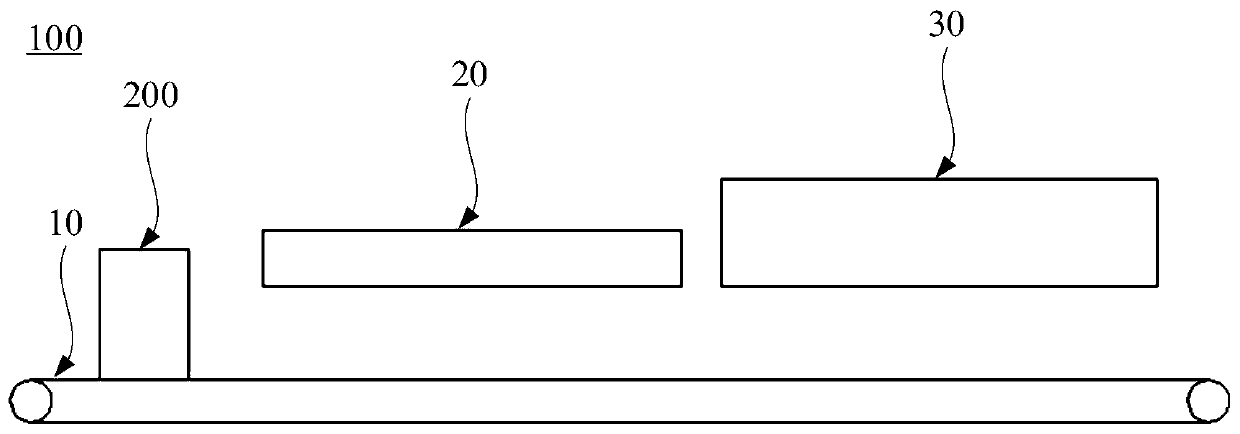

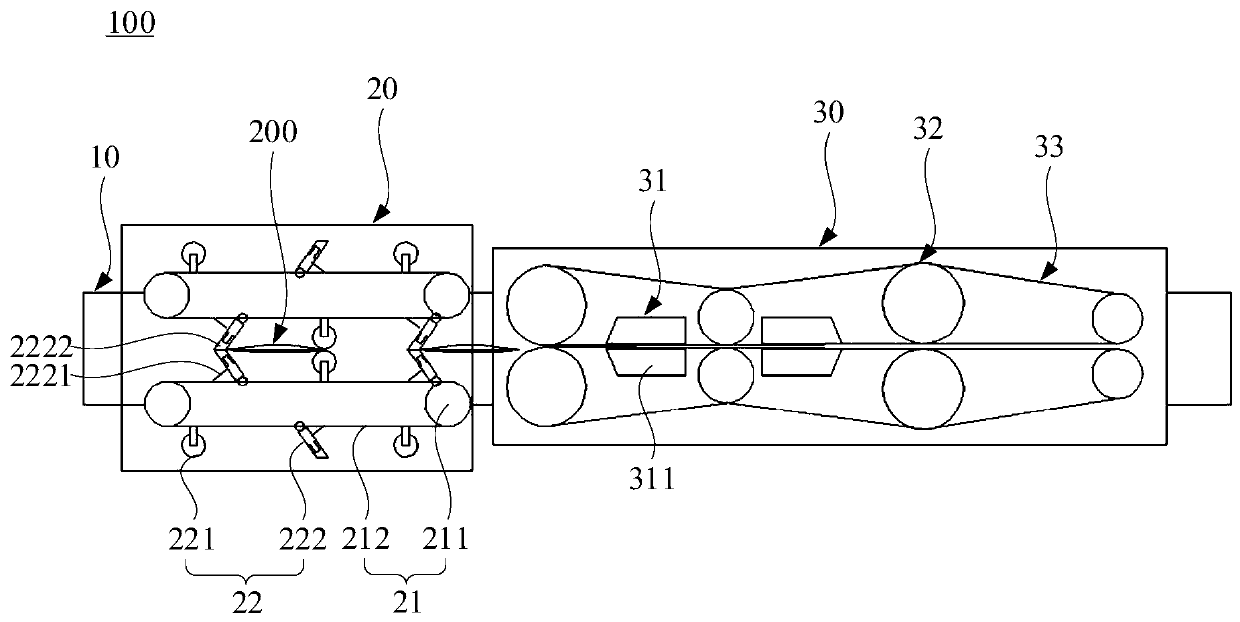

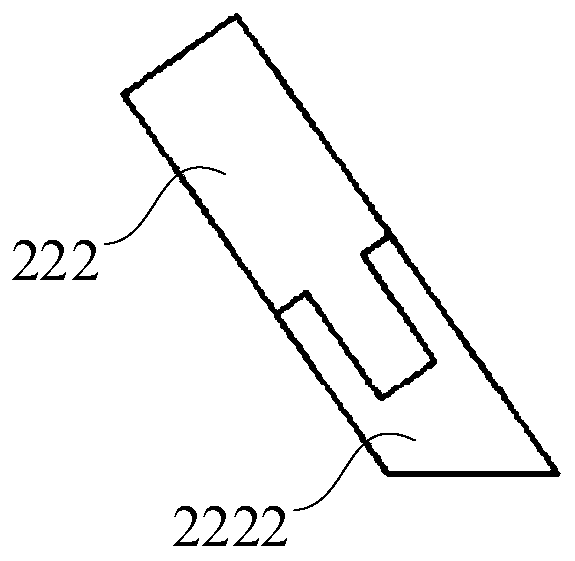

[0029] Please refer to figure 1 and figure 2 , the present embodiment provides a plastic bag heat-sealing device 100, comprising a conveyor belt 10 and a clamping mechanism 20 and a heat-sealing mechanism 30 sequentially arranged above the conveyor belt 10 along the conveying direction of the conveyor belt 10, the clamping mechanism 20 clamps the plastic to be sealed The opening of the bag 200, and cooperate with the conveyor belt 10 to transport the plastic bag 200 to be sealed along the conveying direction. The heat-sealing mechanism 30 is located at the transmission end of the clamping mechanism 20, and the feed port of the heat-sealing mechanism 30 bites the plastic bag 200 to be sealed. The mouth of the bag is heat-sealed, and cooperates with the conveyor belt 10 to send the heat-sealed plastic bag out from the outlet of the heat-sealing mechanism 30 . The plastic bag heat-sealing device 100 can improve the heat-sealing efficiency of plastic bags while reducing labor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com