Shelf alignment method based on latent transfer robot

A technology for handling robots and robots, applied in the field of robots, can solve problems such as inability to perform alignment operations, narrow field of view, etc., and achieve the effects of improving assembly flexibility, large alignment range, and fast alignment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

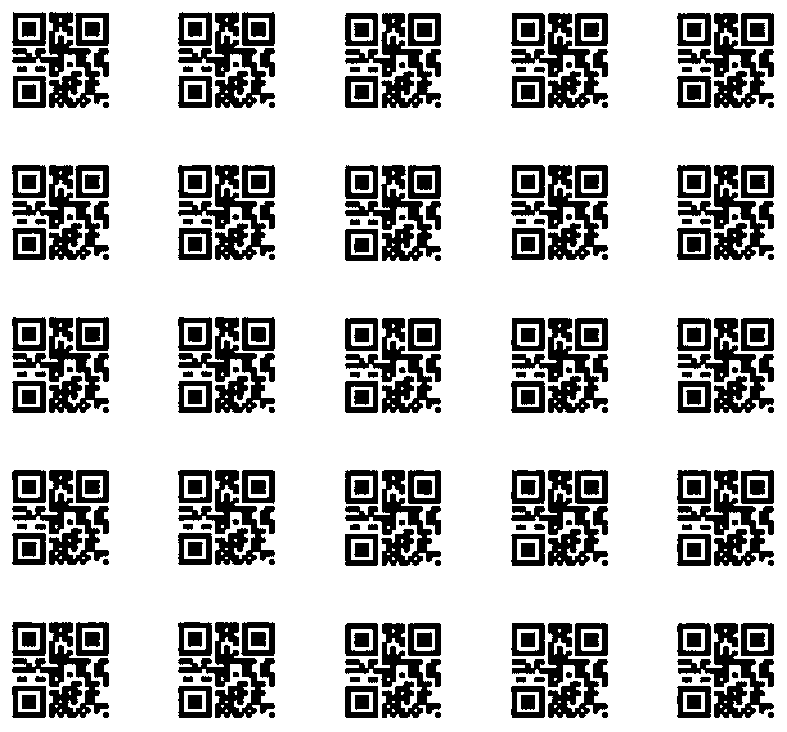

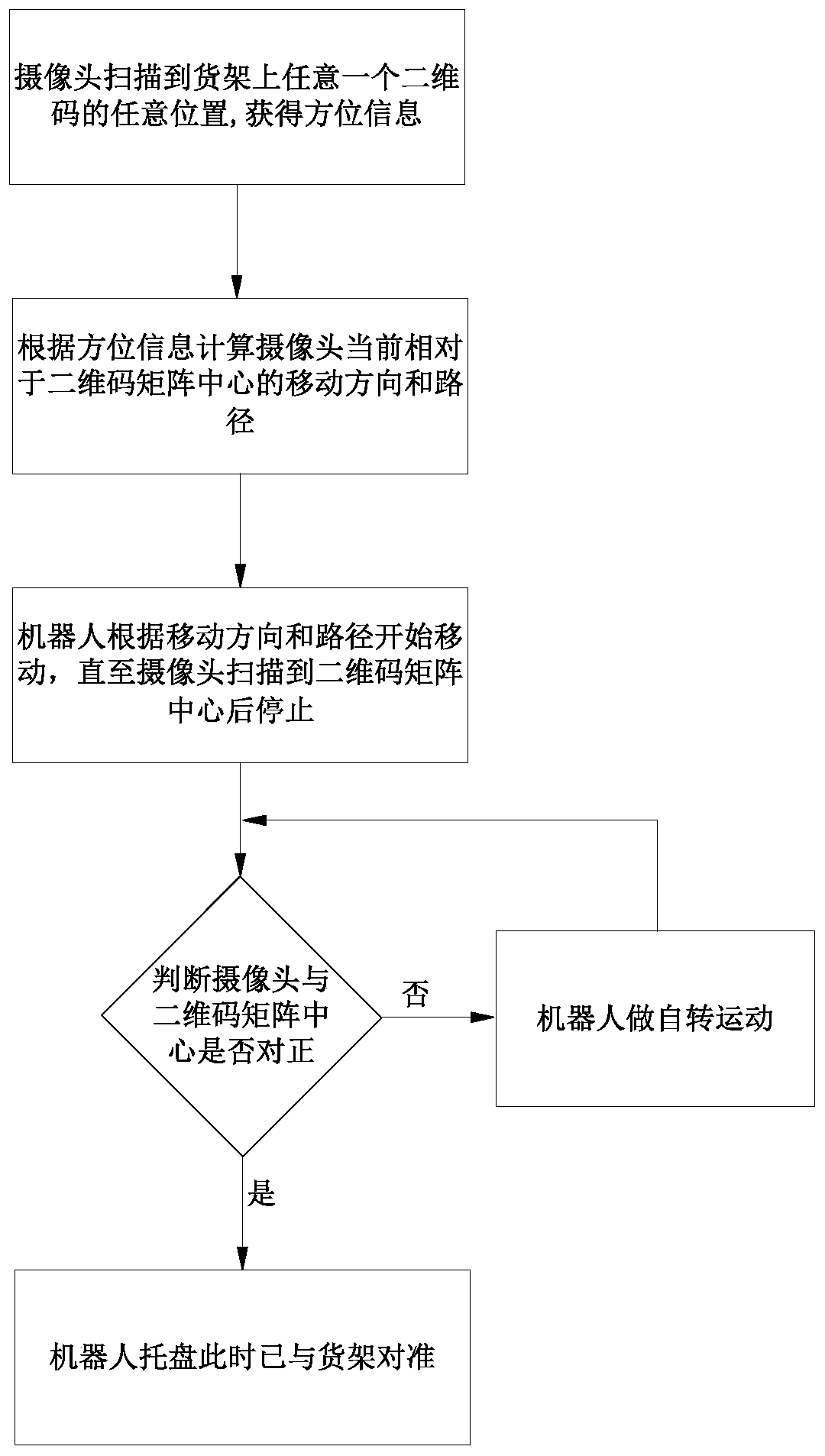

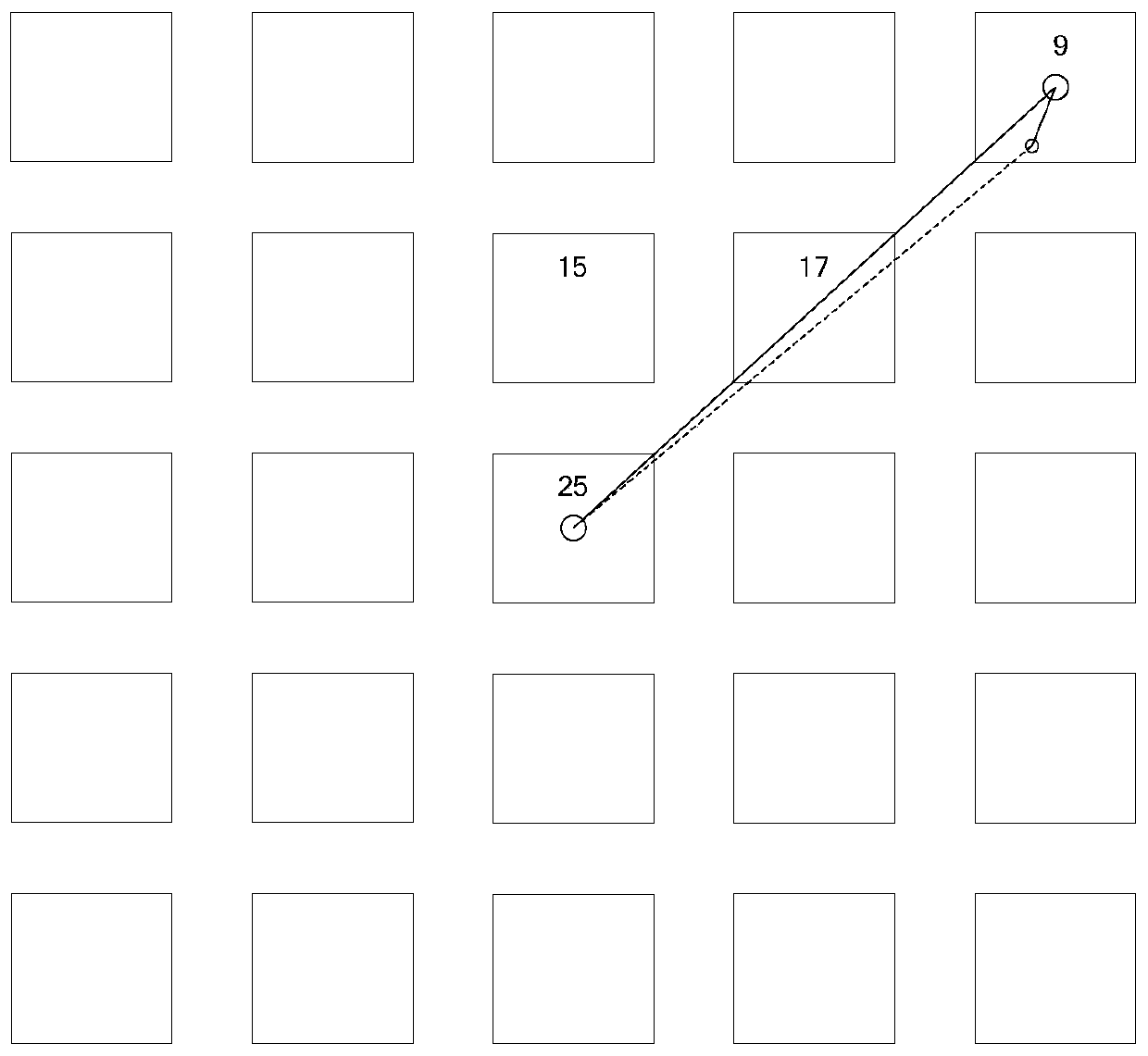

[0023] The present invention provides a solution that can realize the precise alignment between the handling robot and the shelf. Firstly, a two-dimensional code matrix is set on the shelf to realize its alignment with the robot pallet. The specification of the two-dimensional code matrix is a×b, a and b are both natural numbers, and both are greater than 1, such as 5×5, 6×6 or 7×7, such as figure 1 As shown, the intervals between adjacent two-dimensional codes on the two-dimensional code matrix are the same. After the two-dimensional code matrix is set, the implementation process of the present invention is set forth below, as figure 2 As shown, it includes the following steps:

[0024] (1) Turn on the camera on the robot. When the camera scans any position of any QR code on the shelf, obtain the orientation information of the QR code on the center of the QR code matrix and the current position of the camera relative to the center of the QR code. orientation informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com