Method for aligning two points of sticky label paper with two points of vinyl cutter

A technology of cutting plotter and label paper, which is applied in the field of two-point alignment between self-adhesive label paper and computer cutting plotter, can solve the problems of complex control electronic circuit and laser device, slow alignment speed and low alignment accuracy, etc. To achieve the effect of clear vision, easy operation, and improved alignment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

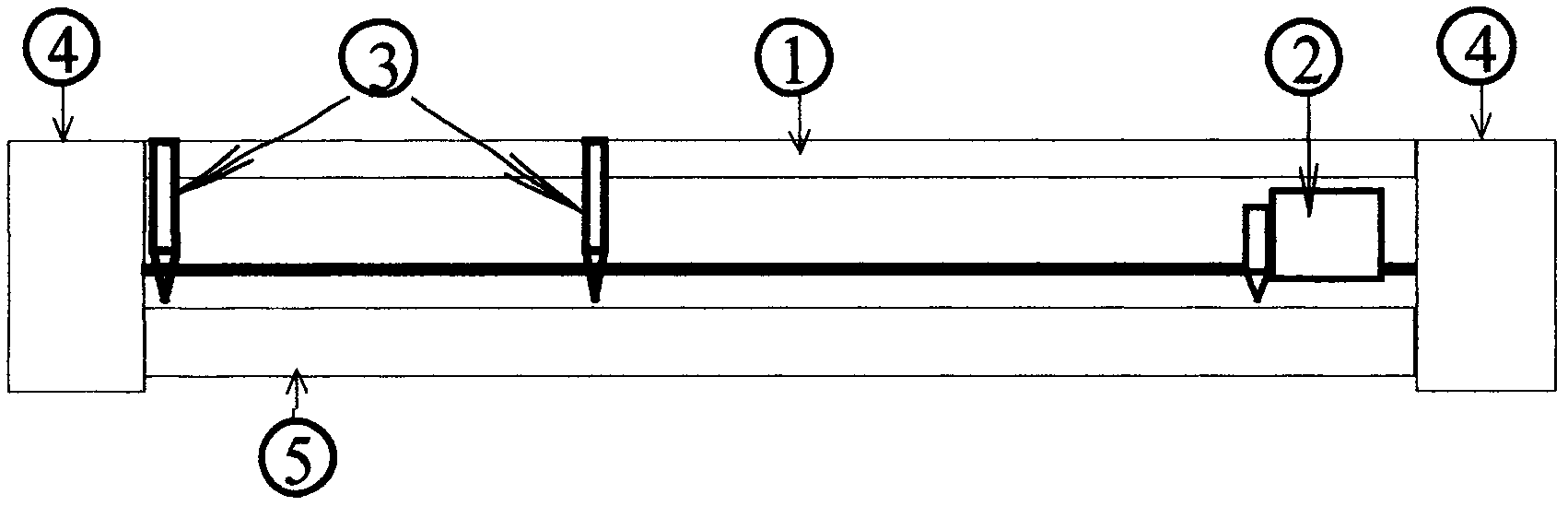

[0013] 1. Press figure 1 As shown, install two pointers on the cutting plotter③;

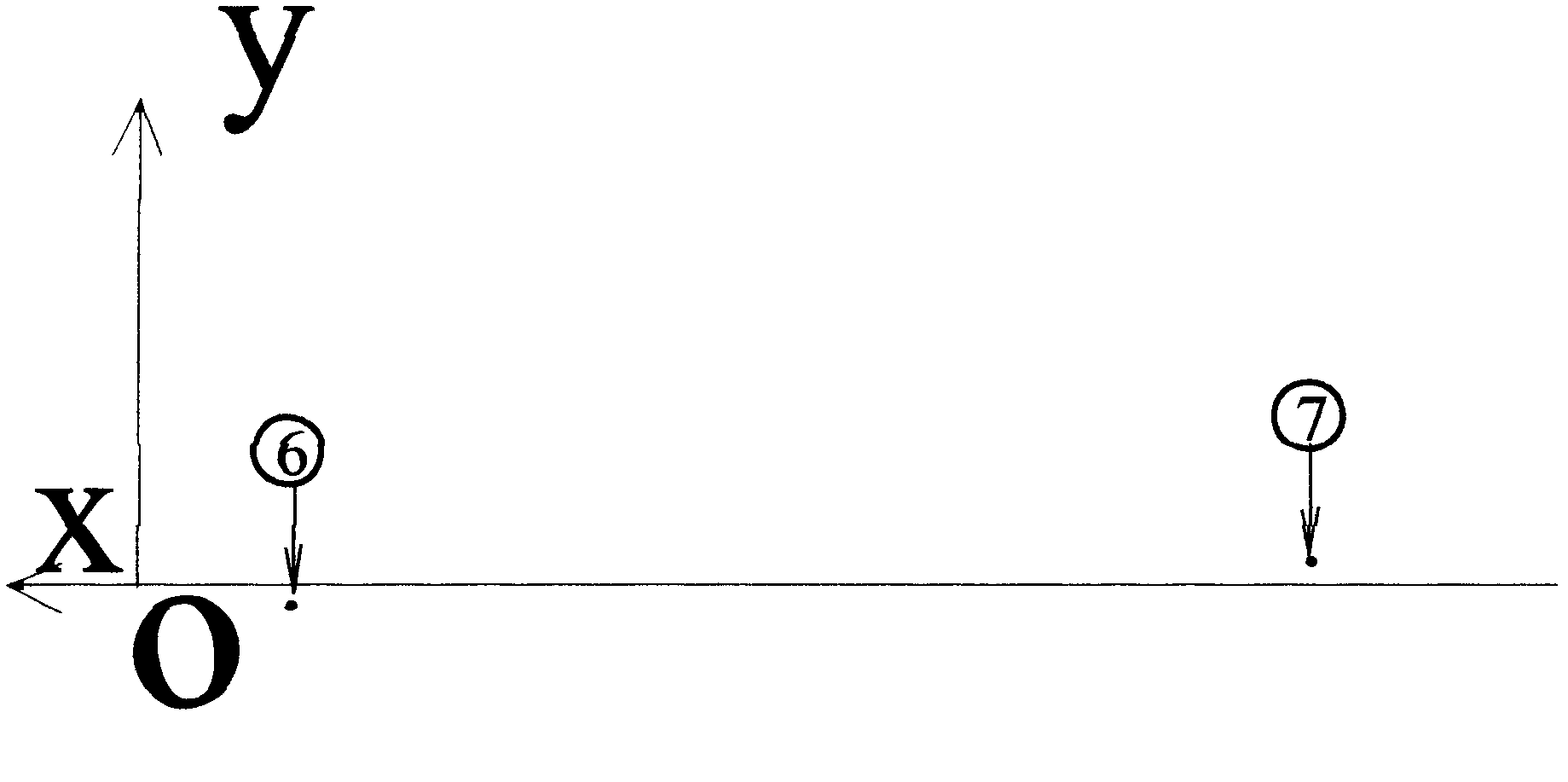

[0014] 2. The tip of the measured pointer points to the coordinate values of two points ⑥M1(a1, b1) and ⑦M2(a2, b2) of the implicit coordinate system XOY of the cutting plotter, a1, b1, a2, b2.

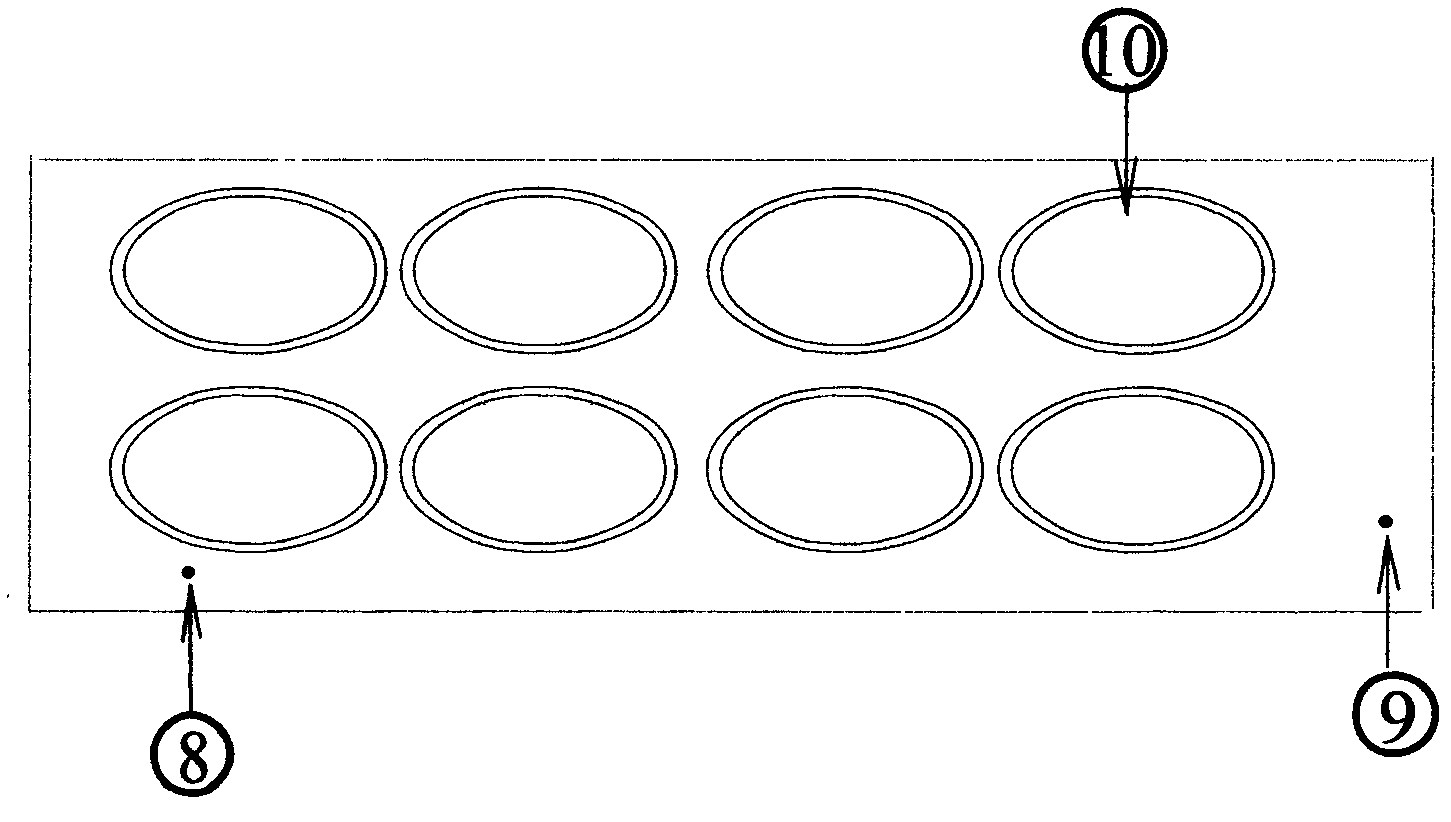

[0015] 3. put image 3 Place it on the cutting plotter, align the alignment coordinate points ⑧m1(a1, b1) and ⑨m2(a2, b2) on the self-adhesive label paper with the tip of the pointer. Press the pressure roller to fix it, and the alignment is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com