Ultraviolet sterilization type atomization device

An atomization device and ultraviolet technology, applied in heating methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of easy aging and damage of the lower shell, inconvenient maintenance or replacement, etc., and achieve easy maintenance Effects of replacement, reduced maintenance costs, improved convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following with attached Figure 1 to Figure 9 The structure of the ultraviolet sterilizing atomization device applying the technical solution of the present invention will be further described.

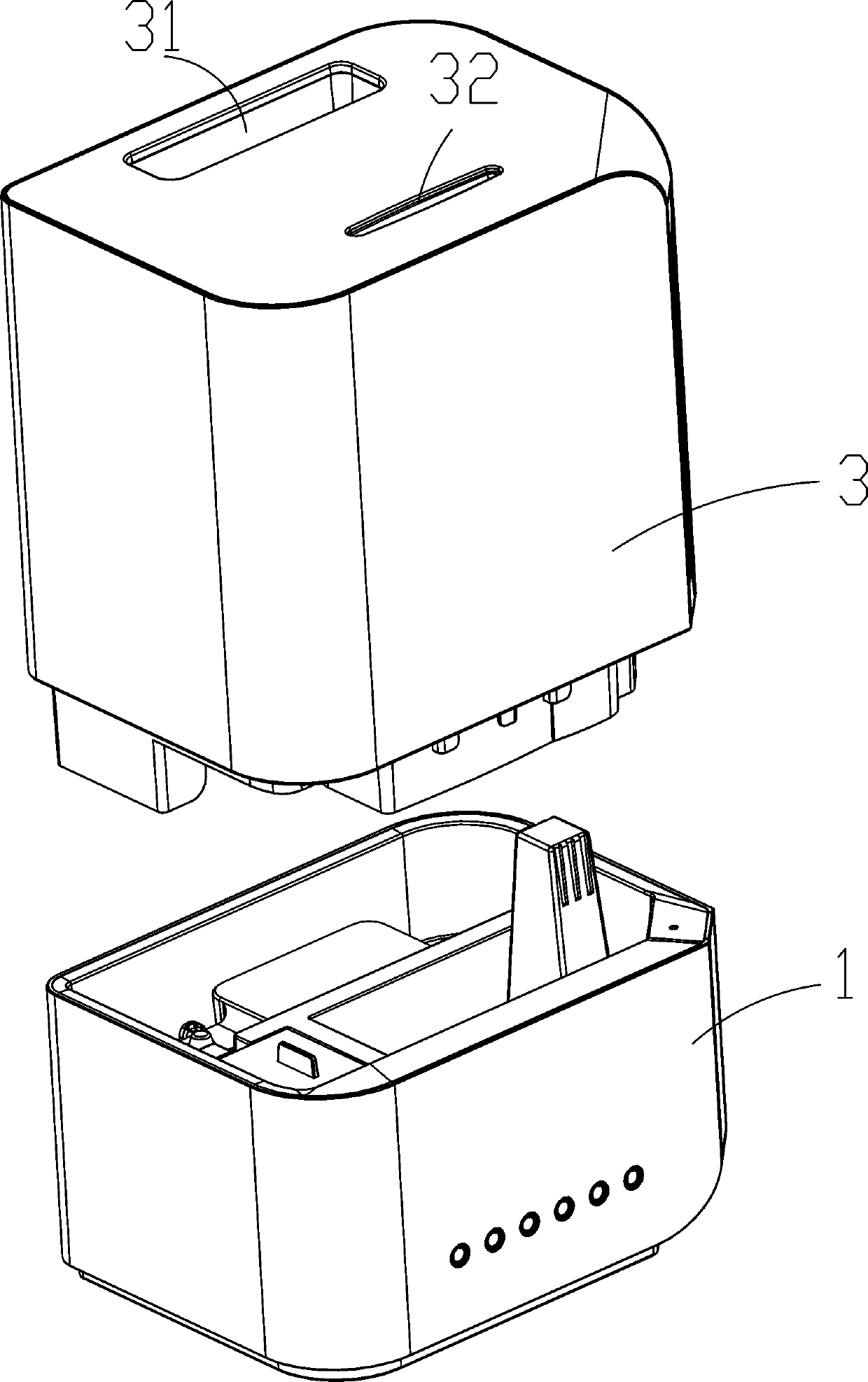

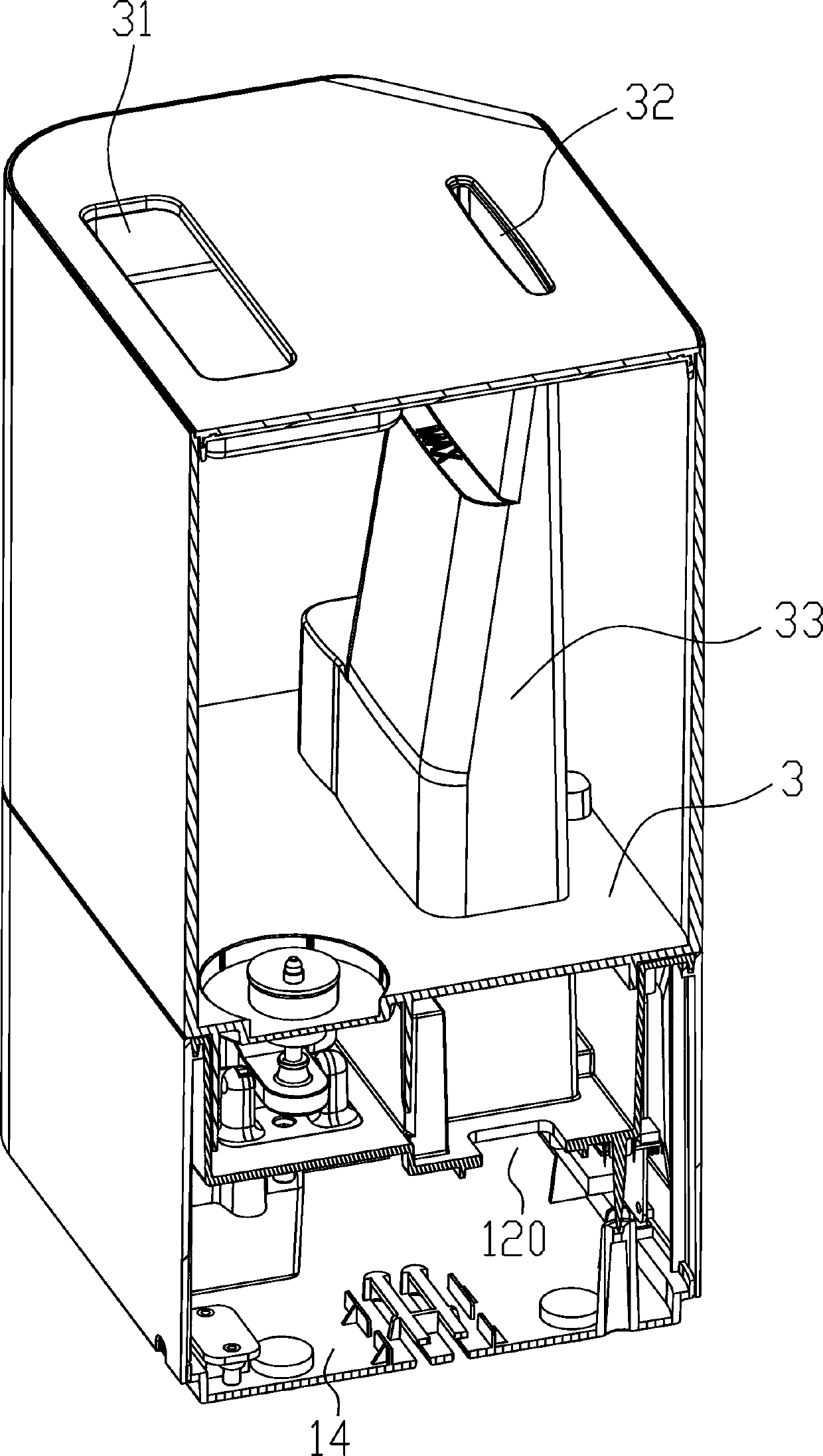

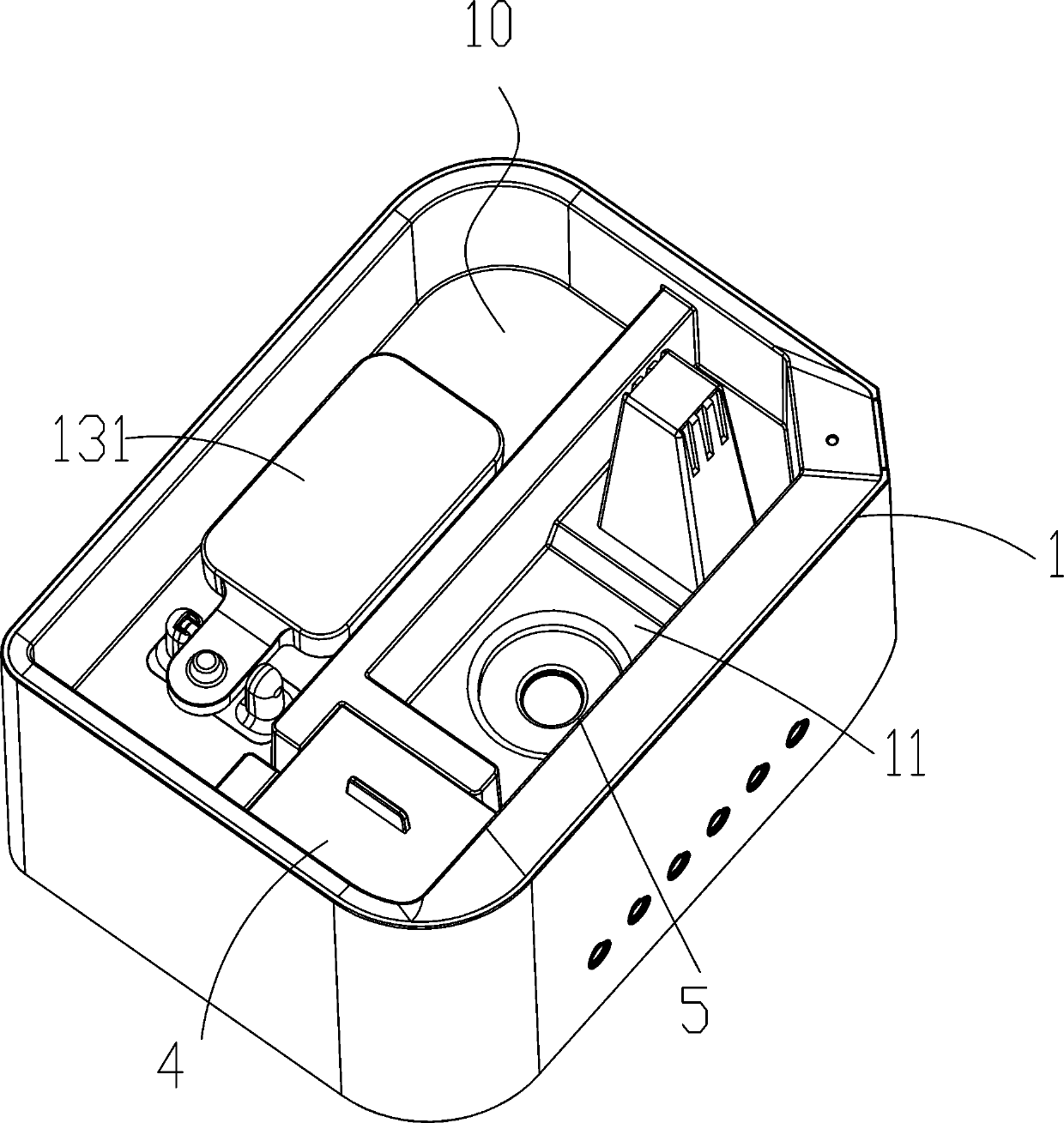

[0044] Such as Figure 1 to Figure 4 As shown, the present invention discloses a new type of ultraviolet sterilizing atomizing device. As an expression of the atomizing device, the atomizing device is a humidifier, and the humidifier includes an atomizing working part 1, The atomization working part 1 is the foundation of the whole equipment resting on the ground or the desktop; it also includes a blower mechanism 2 and a liquid tank 3, and the liquid tank 3 is arranged on the atomization working part 1, which is used for The atomized liquid is stored with a water inlet 31 on the top, an air induction channel 33 and a mist outlet 32 in the middle, and the air introduction channel 33 communicates with the mist outlet 32 and the atomization chamber 11 described below; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com