Gas stove with automatic cooling igniter and control method thereof

A technology of automatic cooling and control method, applied in the field of gas stoves, can solve the problems of reducing the service life of components, damage, temperature rise, etc., and achieve the effect of prolonging the service life and ensuring stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

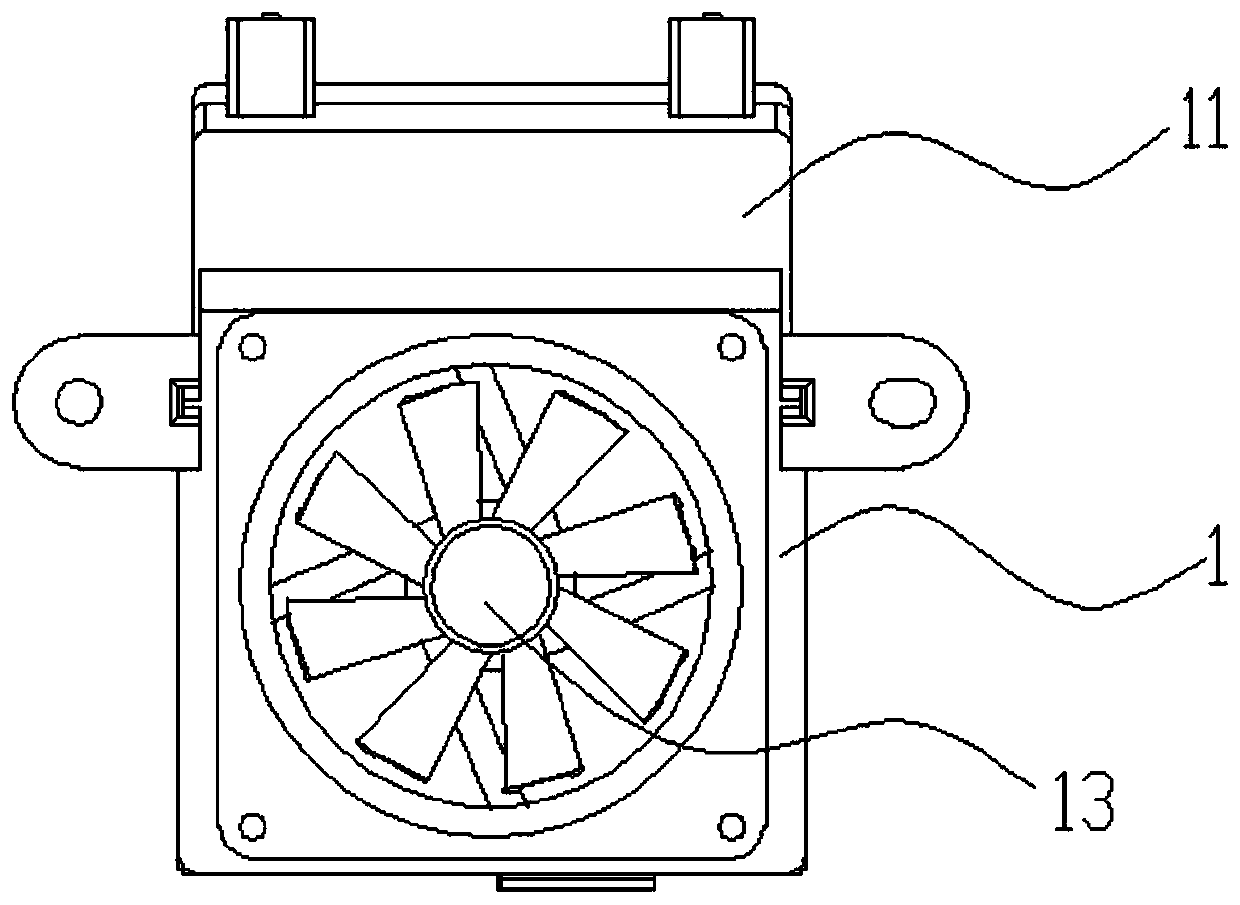

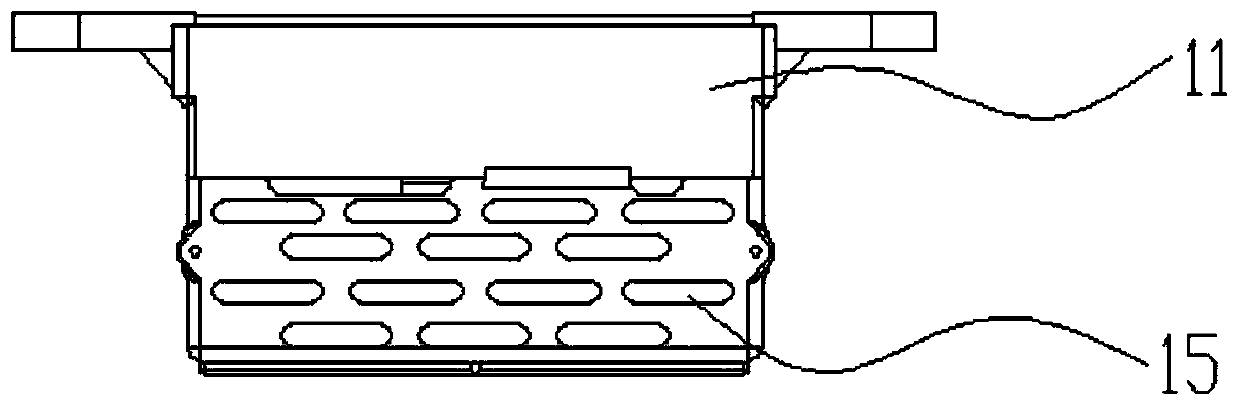

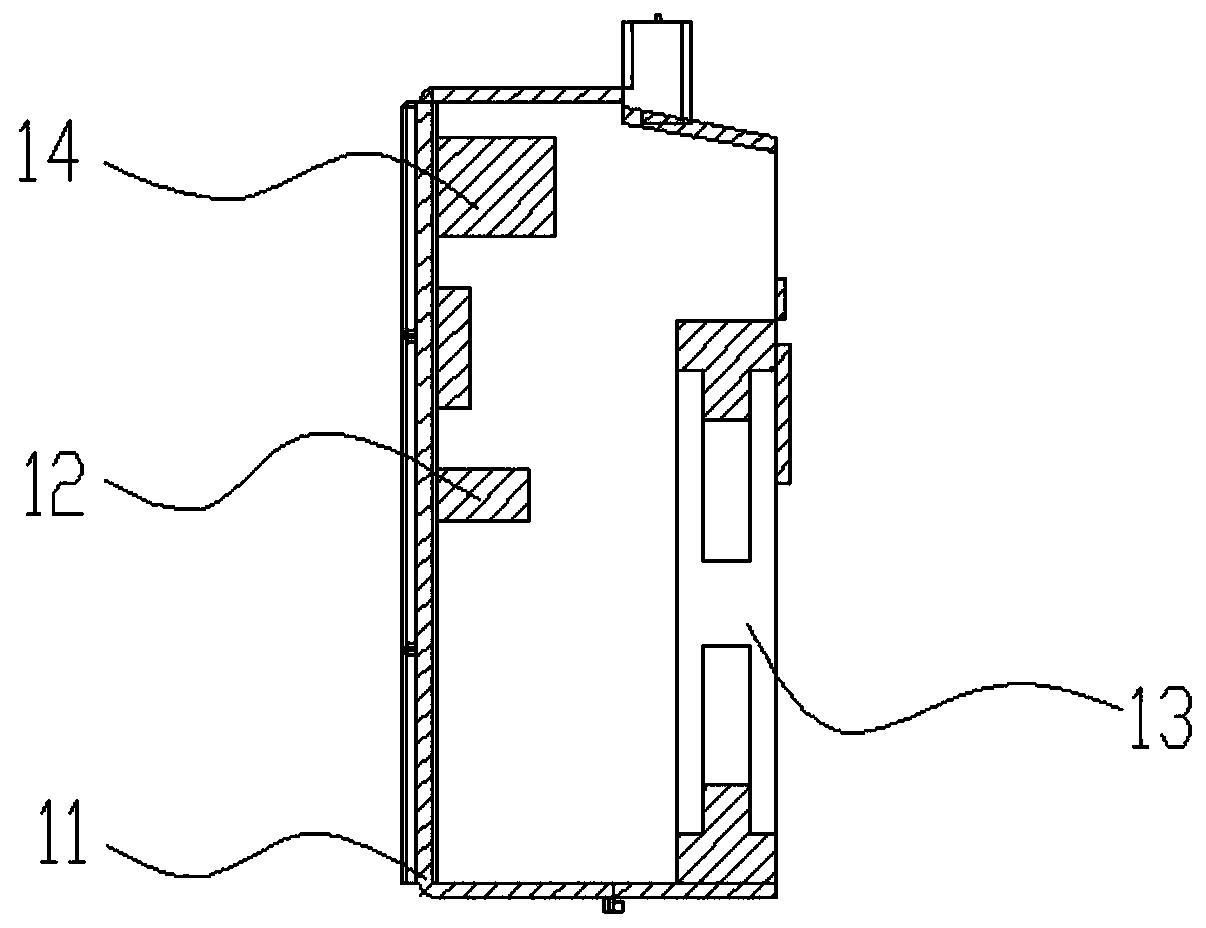

[0023] Participate in the attached Figure 1-3 A gas stove with an igniter capable of automatically cooling down according to the present invention includes a gas stove body, and an igniter 1 is provided in the gas stove body. The igniter 1 includes a housing 11, a controller 12, and a heat sink 13 and a temperature measuring component, the controller 12 is arranged in the housing 11, the heat sink 13 and the temperature measuring component are both arranged on the housing 11, and the controller 12 is respectively connected to the The heat sink 13 and the temperature measuring component are electrically connected. Preferably, a ventilation hole 15 is provided on the housing 11, so that the heat dissipation effect is better. Preferably, the heat dissipation device 13 is a heat dissipation fan, and an opening is provided on the housing 11, and the heat dissipation fan is installed in the opening. A heat dissipating device 13 is provided on the housing 11 of the igniter 1 to act...

Embodiment 2

[0027] Participate in the attached Figure 4 Shows a control method of a gas stove with an automatic cooling igniter of the present invention, which is applied to the gas stove in Embodiment 1. The control method includes the following steps: detecting whether there is an ignition signal S1; if there is an ignition signal , Then detect whether the ignition is successful S2; if the ignition is successful, detect the real-time temperature S3 in the igniter; determine whether the real-time temperature is higher than the preset maximum temperature S4; if the real-time temperature is higher than the preset maximum temperature, start the heat sink S5. In this embodiment, the preset maximum temperature is 85°C.

[0028] After starting the heat dissipation device, it also includes the following steps: detecting whether the real-time temperature in the igniter is lower than the preset minimum temperature S6; if the real-time temperature is higher than the preset minimum temperature, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com