Anti-cracking brake drum and manufacturing method thereof

A manufacturing method and a technology for brake drums, which are applied in the directions of brake drums, manufacturing tools, casting and molding equipment, etc., can solve the problems of easy cracking of the brake drum and easy disengagement of the circle of the brake drum, so as to achieve not easy deformation and cracking, and good heat resistance. Ability to ensure the effect of malleability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

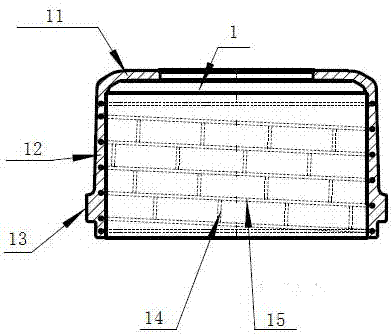

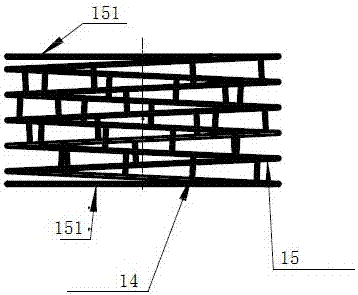

[0031] refer to figure 1 As shown, an anti-cracking brake drum is provided in one embodiment of the present invention, which includes a brake drum body, the brake drum body 1 includes a top surface 11 and a cylinder extending vertically downward along the circumference of the top surface 11 Surface 12; the inner wall surface of the cylindrical surface 12 is provided with a multi-turn threaded spiral rib 15, and a connecting rib 14 is arranged between the spiral ribs 15 of adjacent circles; the spiral rib 15 at the starting point and the end point of the inner wall surface is a straight ring Paragraph ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com