Method for controlling unbalance of APU rotor assembly

A control method and technology of balancing quantity, which are applied in static/dynamic balance testing, machine/structural component testing, and measuring devices, etc., which can solve the problem of inaccurate measurement results of balancing machines, unstable operation, fly-out of key gear shafts, etc. It can achieve the effect of simple and convenient measurement and calculation, convenient measurement process and personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Taking the bearing shaft in the APS5000 APU used on the Boeing 787 aircraft as an example, the method for controlling the unbalance of the APU rotor assembly of the present invention will be specifically introduced.

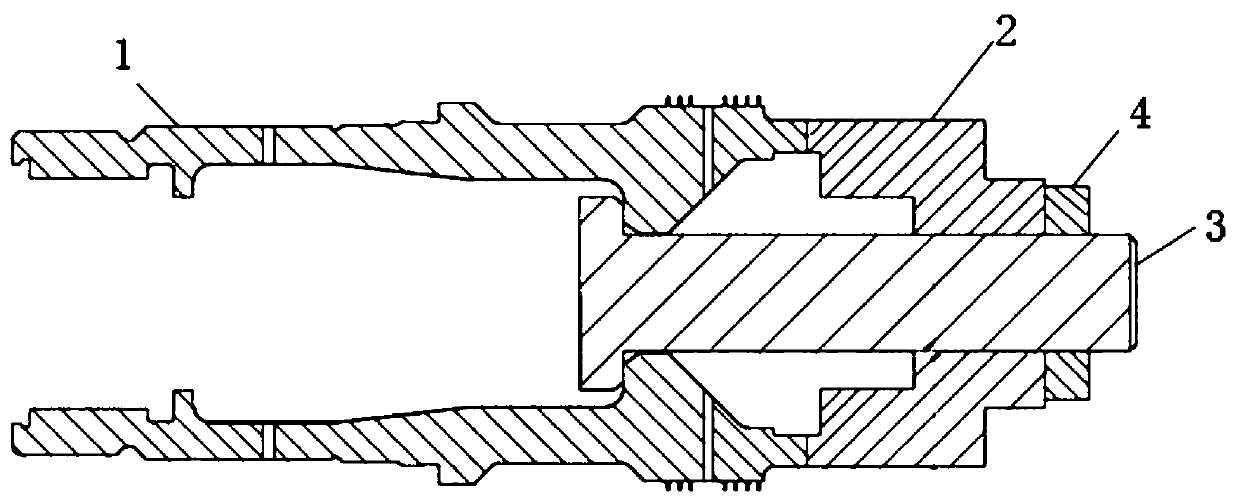

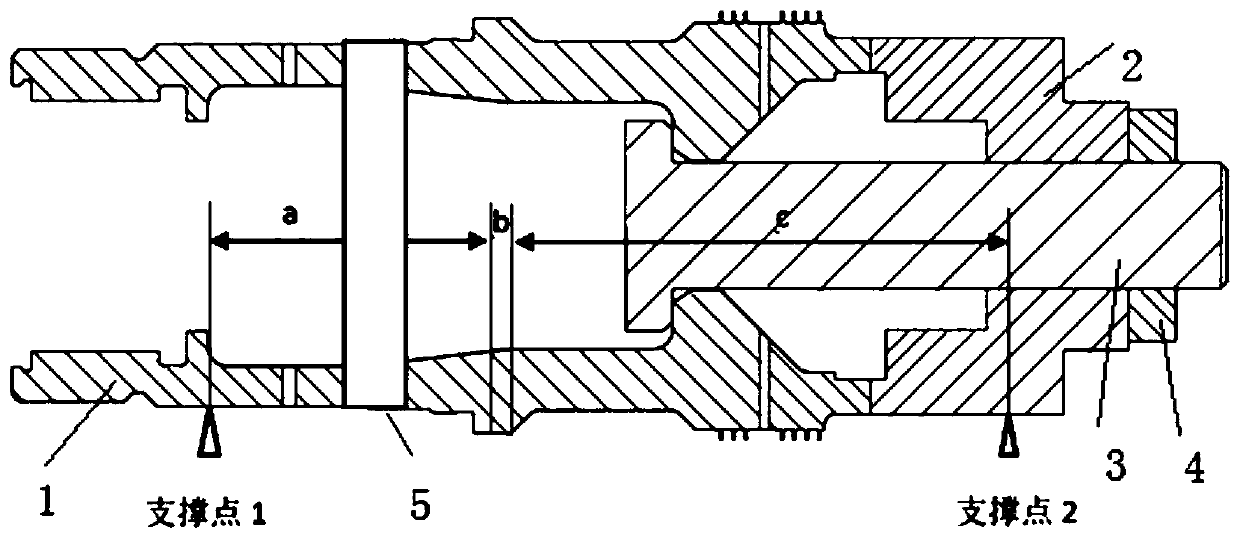

[0032] A method for controlling the unbalanced amount of an APU rotor assembly. First, each part in the rotor assembly including a bearing shaft is individually balanced, and then assembled together for overall balancing. The difference from the prior art is that the bearing shaft of the rotor assembly of the present invention is individually balanced before the overall balance is performed.

[0033] APS5000 Model APU Bearing Shaft Structure Introduction

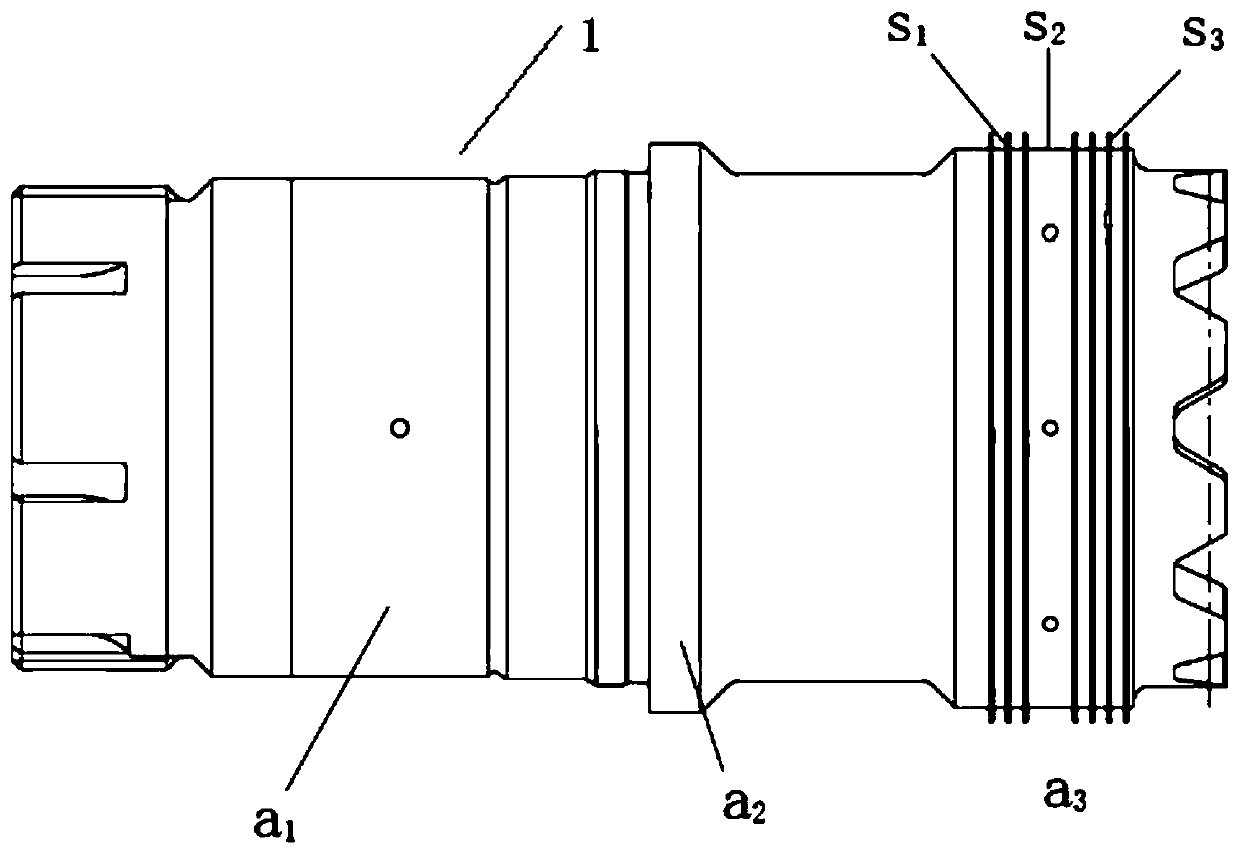

[0034] figure 1 It is a schematic diagram of the structure of the APS5000 model APU bearing shaft. The main differences between the short shaft structure and common shafts are as follows: 1. Single tooth connection. 2. Large quality and small volume. 3. There is only one location for balanced materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com