Aero-engine air intake distortion simulation device

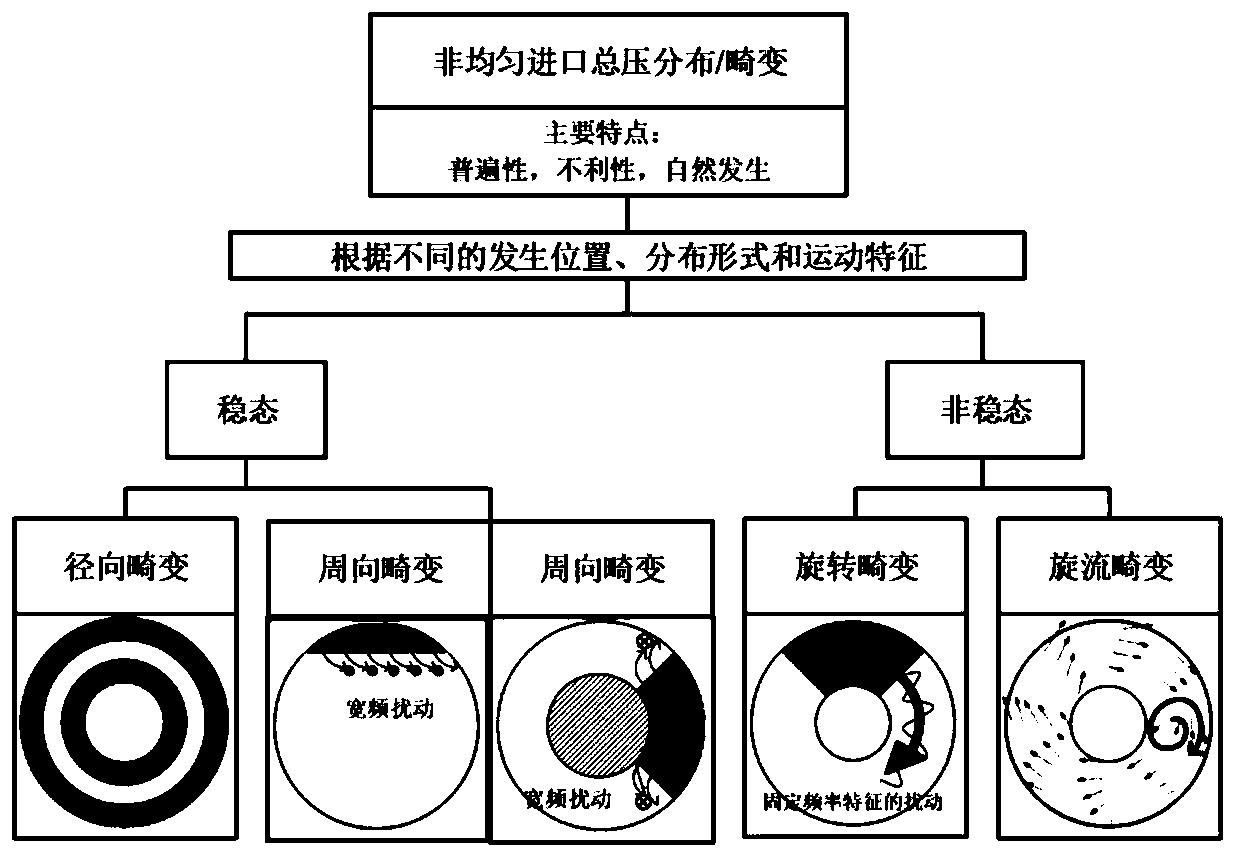

An aero-engine and simulation device technology, applied in the field of turbomachinery technology and aero-engine, can solve the problems of performance loss, rarely developing engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

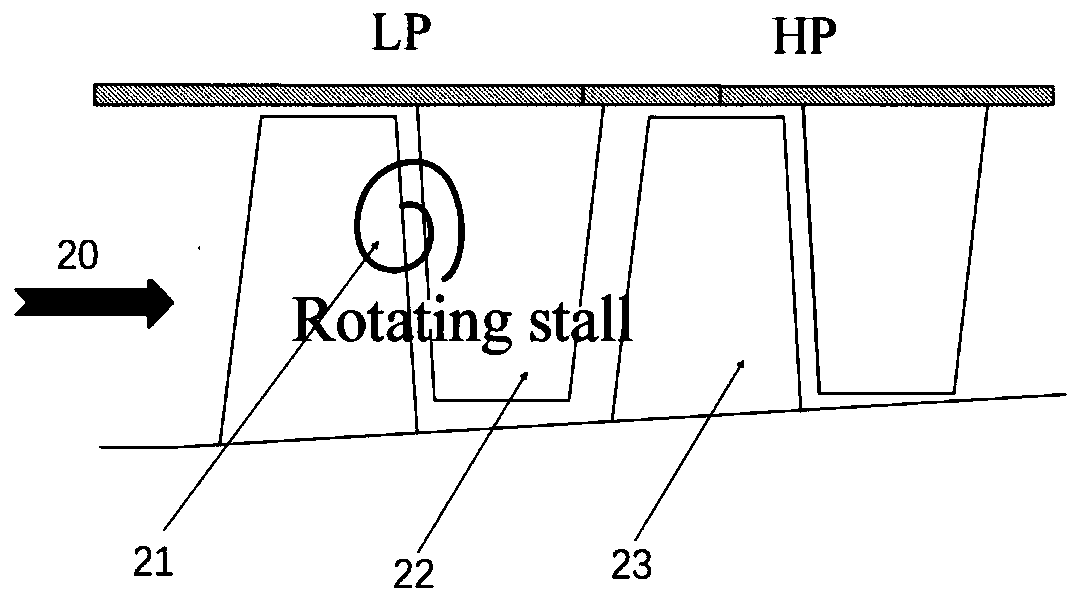

[0052] Embodiment 1 (rotation distortion generating device)

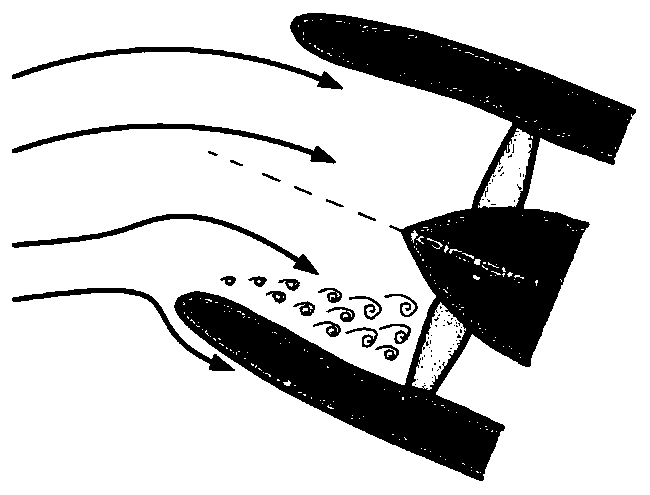

[0053] This embodiment provides an air intake distortion simulation device for an aero-engine, which can cause the airflow to enter the aero-engine to generate rotational distortion before entering the air intake lip of the aero-engine, thereby realizing the simulation of rotational distortion.

[0054] Such as Figure 5 and Figure 6 As shown, the aeroengine intake distortion simulation device of this embodiment includes: four spoiler screens 2 , a drive motor 3 , a frequency converter (not shown in the figure) and a bracket 6 .

[0055] The bracket 6 is used to support the driving motor 3 so that the driving motor 3 can normally drive the rotation of the spoiler screen 2 . The position of the bracket 6 should make the axis of the drive motor 3 align with the axis of the air intake lip of the air intake passage 5 of the aero-engine, so that the intake air flow can enter the air intake lip smoothly.

[0056] The ...

Embodiment 2

[0066] Embodiment 2 (swirl distortion generating device)

[0067] This embodiment provides an air intake distortion simulation device for an aero-engine, which can cause the airflow to enter the aero-engine to generate swirl distortion before entering the air intake lip of the aero-engine, thereby realizing the simulation of swirl distortion.

[0068] Such as Figure 7 As shown, the aeroengine intake distortion simulation device of this embodiment includes: eight flat guide vanes 12 , a servo motor 13 and a bracket 16 .

[0069] The bracket 16 is used to support the servo motor 13, so that the servo motor 13 can be normally used for mounting ring installation. The position of the bracket 16 should make the axis of the servo motor 13 align with the axis of the air intake lip 14 of the air intake channel 15 of the aero-engine, so that the intake air flow can enter the air intake lip 14 smoothly.

[0070] Eight flat guide vanes 12 are arranged on the air intake side of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com