Lubricating grease detection mold

A technology for detecting molds and grease, applied in the investigation stage/state change and other directions, can solve the problems of damage, difficulty in ensuring the repeatability of the thickness of the grease film in the grease cup 1, easy to poke the grease film of the grease film, etc., and achieve a stable relative position. , to achieve repeatable and complete, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

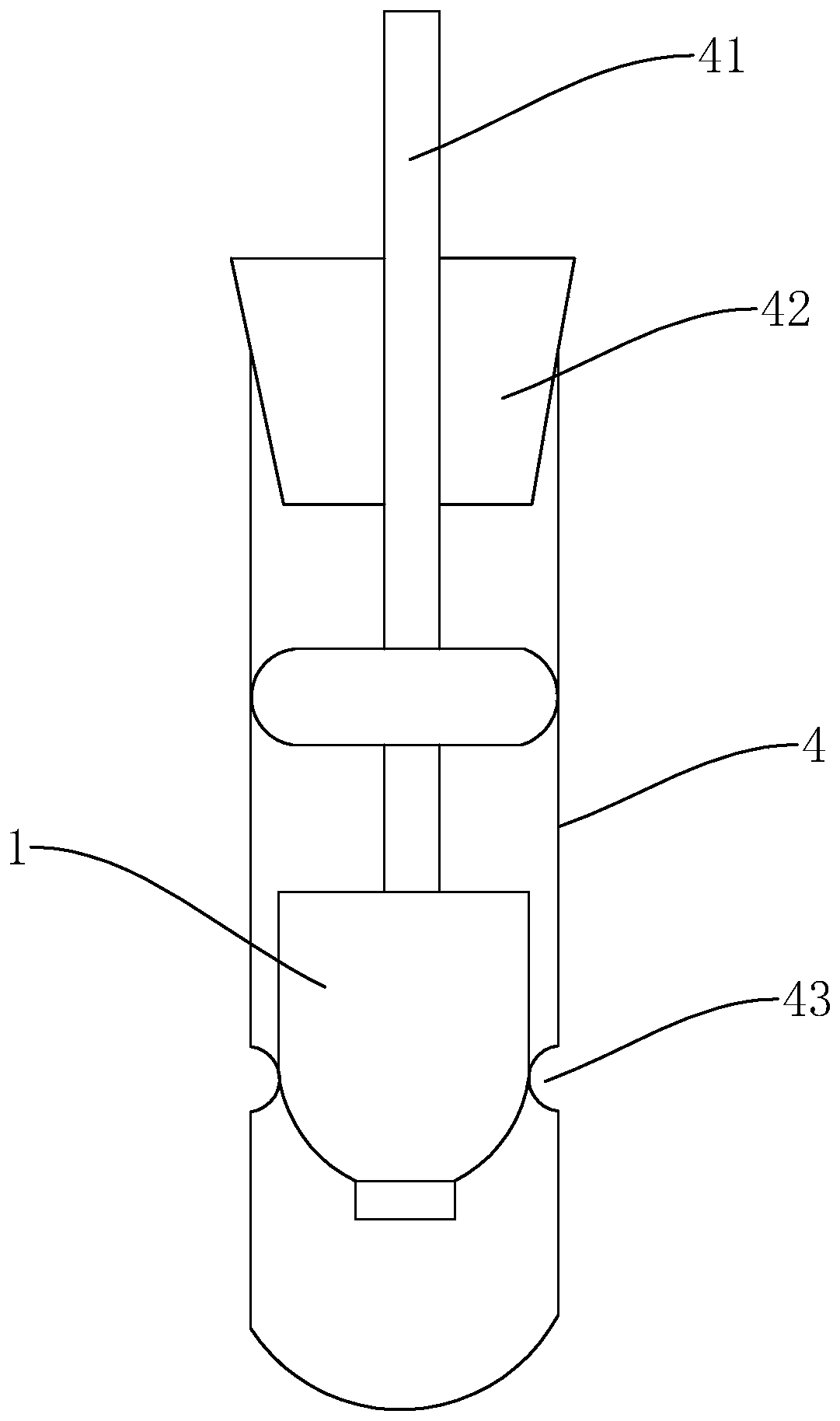

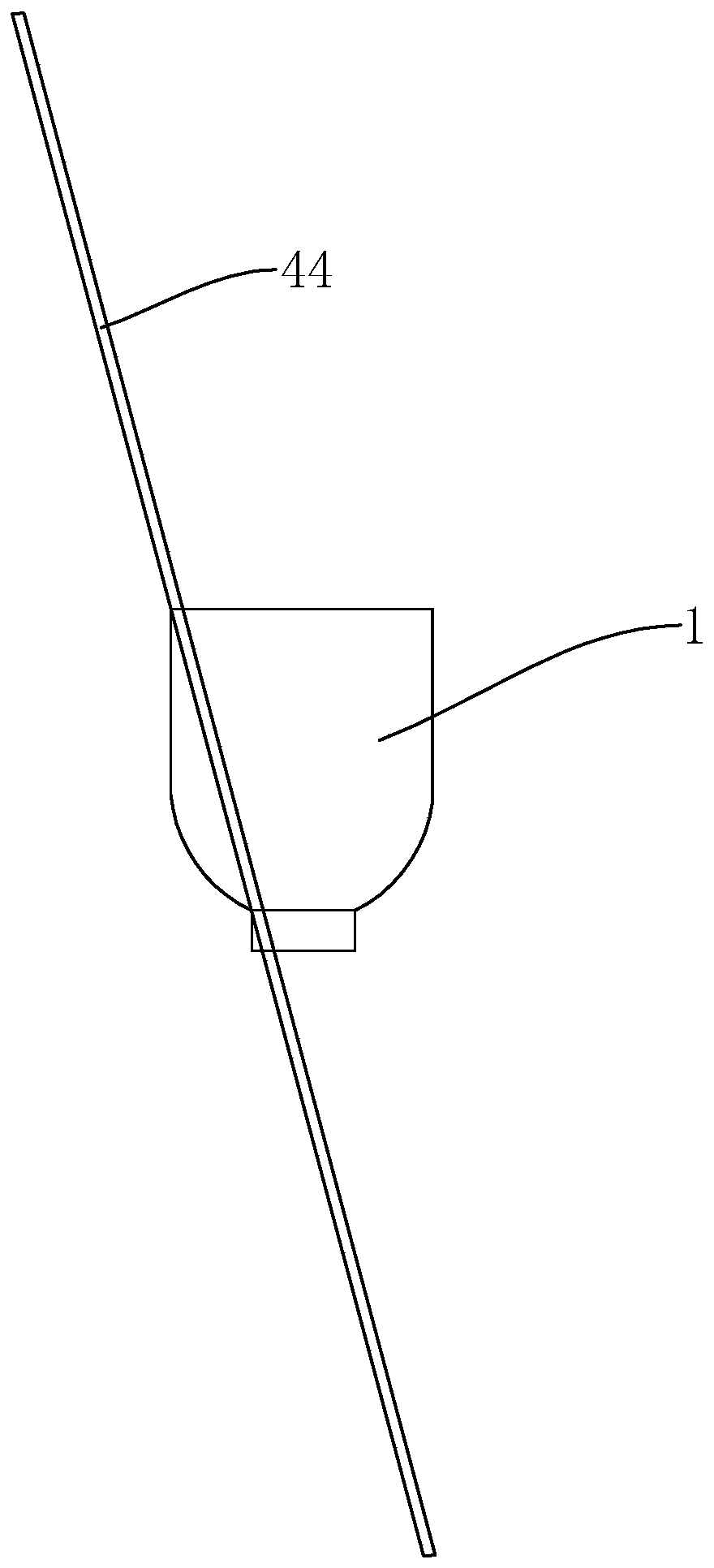

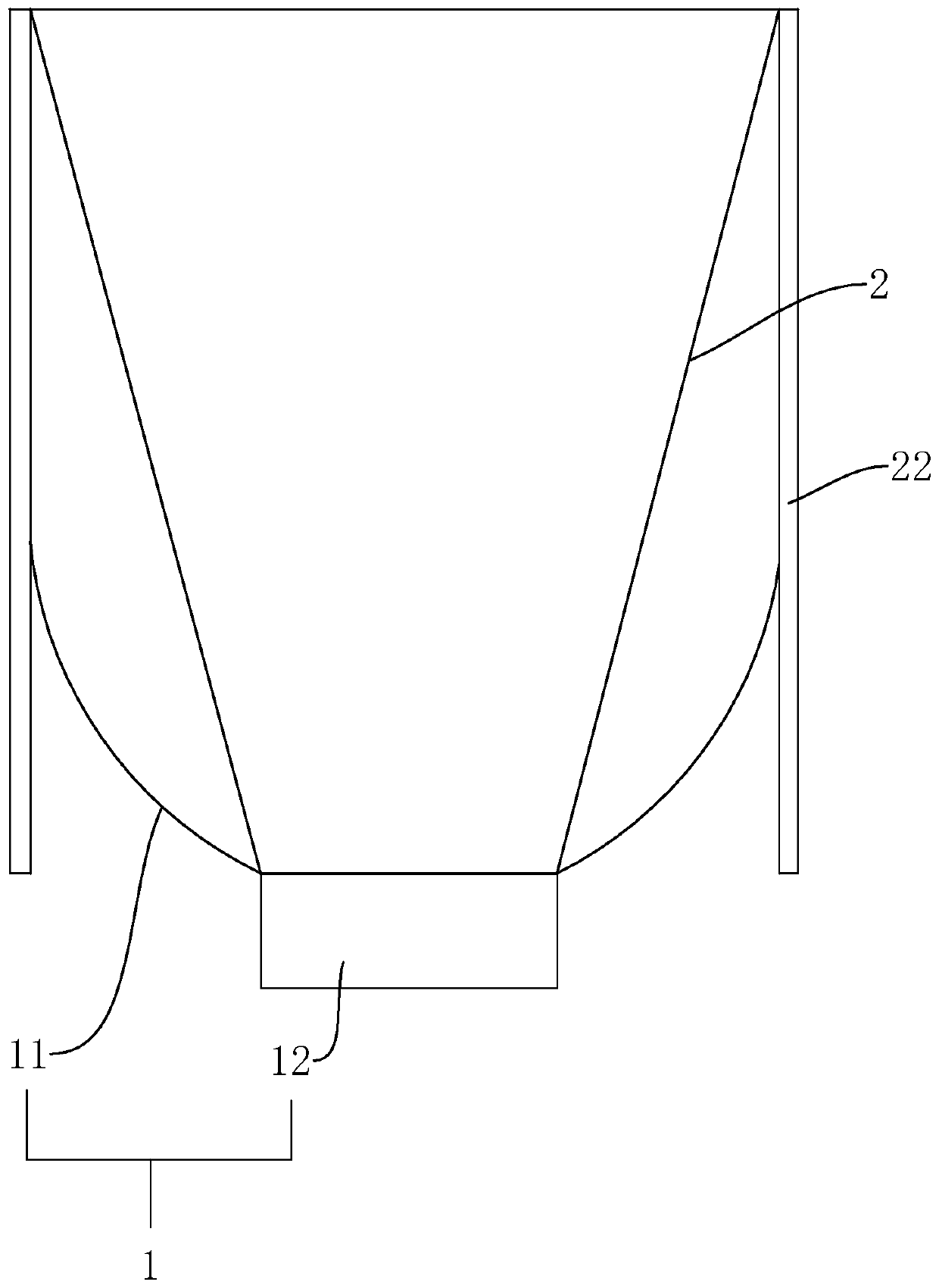

[0025] refer to image 3 , the invention discloses a lubricating grease detection mold, including a grease cup 1, the grease cup 1 includes a bowl-shaped bowl 11 and a tube 12 located directly below the bowl 11 and communicating with the bowl 11 in a vertical direction, the bowl The portion 11 is co-linear with the central axis of the pipe portion 12 . The grease cup 1 is made of chrome-plated brass, which has the characteristics of wear resistance and corrosion resistance. Fitting parts are arranged inside the fat cup 1 , and the fitting parts cooperate with the metal rod 44 to form a fat film in the fat cup 1 .

[0026] refer to image 3 and Figure 4 , the matching parts include a partition cone 2, the partition cone 2 is funnel-shaped with a wide top and a narrow bottom, and the top and bottom of the partition cone 2 are all openings. The separation cone 2 is of the same height as the bowl portion 11 of the fat cup 1 and the central axes are collinear. The top and bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com