A multi-size compatible wafer grinding equipment

A multi-size and equipment technology, applied in grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of thin water layer discovery, tedious and time-consuming processing of water layer, unfavorable processing and use, etc., to achieve the effect of flexible protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

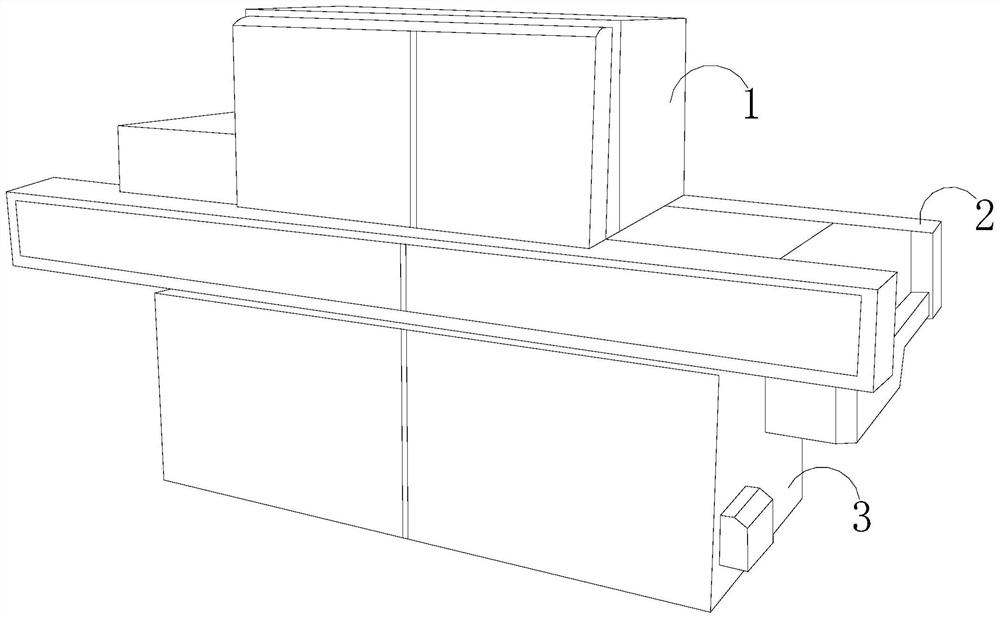

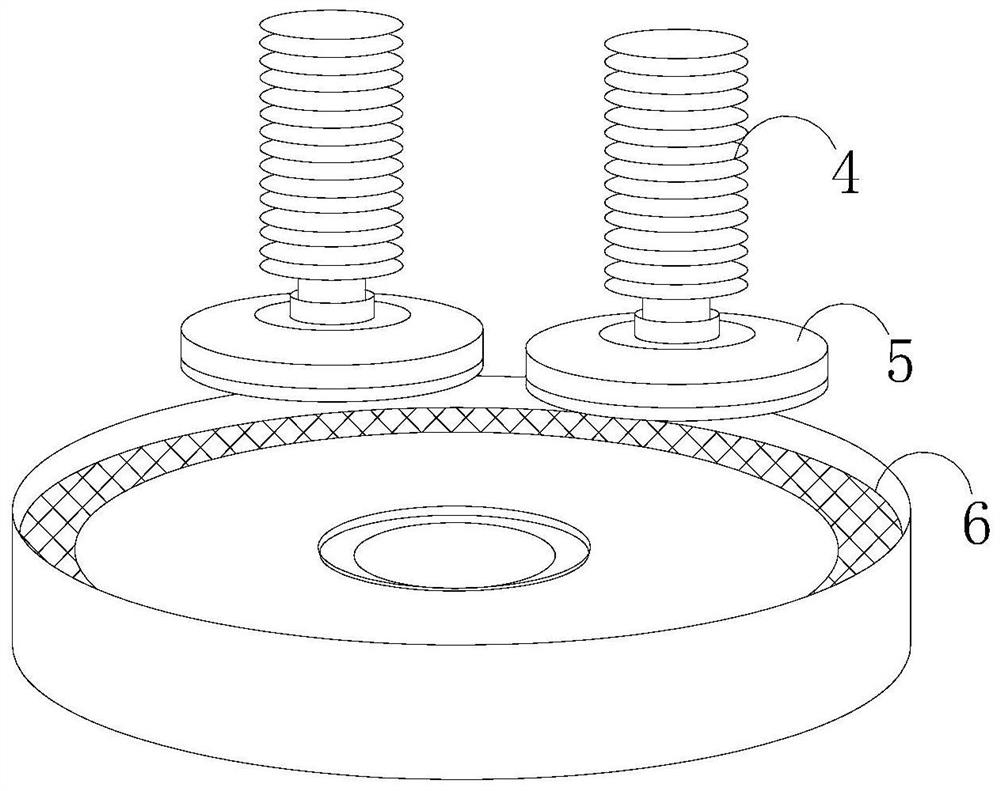

[0030] like Figure 1-Figure 4 As shown, the present invention provides a multi-size compatible wafer grinding equipment, the structure of which includes a grinding chamber 1, a support platform 2, and a control cabinet 3. The grinding chamber 1 is provided with a lifting rod 4, a grinding disc 5, Alignment table 6, the lift rod 4 and the grinding disc 5 are mechanically connected, the grinding disc 5 is arranged on the upper end of the alignment table 6, there are two grinding discs 5, the grinding processing chamber 1 The signal end of the control box 3 is electrically connected to the signal output end of the control box 3, and the support platform 2 is horizontally fixed between the grinding chamber 1 and the control box 3,

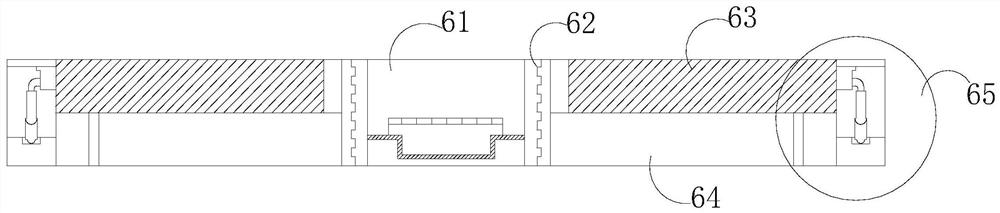

[0031] The alignment table 6 is provided with a push-out shaft 61 , a meshing pattern 62 , a sliding cover 63 , a stage 64 , and a cover side sliding mechanism 65 . The sliding cover 63 is covered on the stage 64 by the horizontal sliding mechanism 6...

Embodiment 2

[0033] like Figure 5-Figure 7As shown, based on the moisture-proof foundation of Embodiment 1, the sliding cover body 63 is composed of a magnetic ring 631, a magnetic disk 632, and a cover surface 633, and the cover surface 633 is located at one end of the push-out shaft 61. The magnetic ring 631 and the magnetic disk 632 are mutually different magnets, and they are adsorbed and fixed. The magnetic disk 632 is arranged inside the empty slot, and there are four magnetic disks 632, each of which is arranged on the same side. Pleated structure, the cover surface 633 is located at the upper part of the empty groove after shrinking to form a circular plane with the stage 64, the telescopic cylinder 653 is multi-stage, and the height change distance is the distance between the sliding cover 63 when the stage 64 is opened The distance is the same, that is to say, the sliding cover 63 can be used to open the stage 64 well by the driving of the telescopic cylinder 653. The push-out s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com