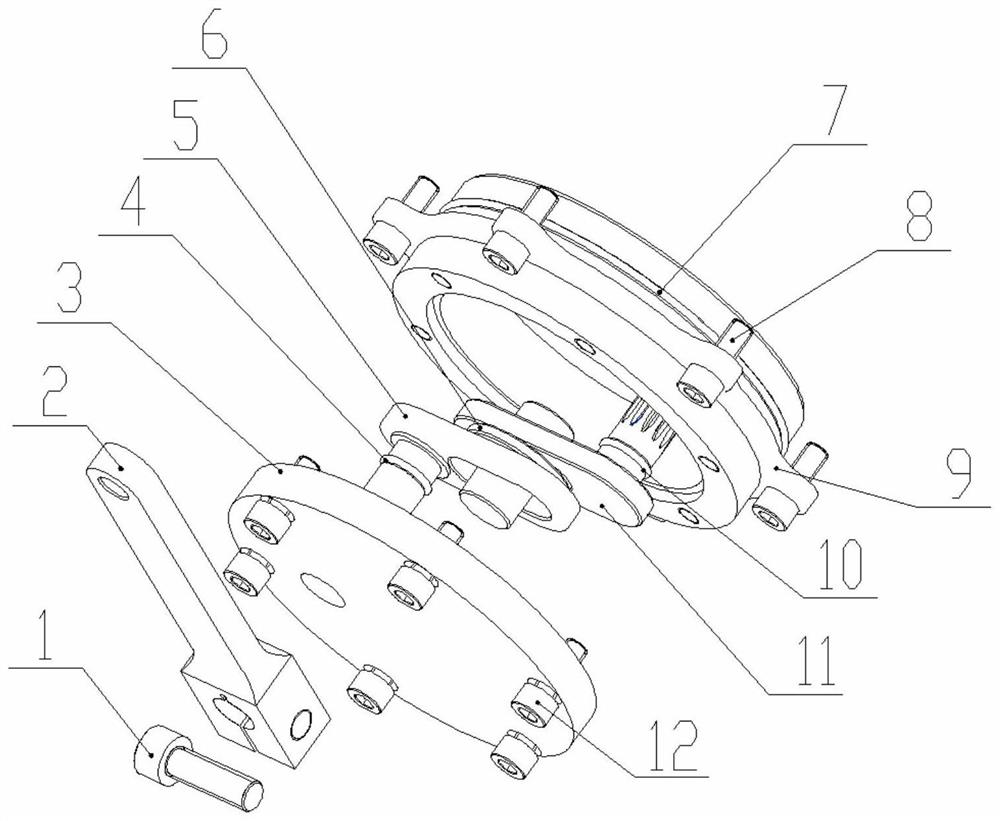

Equal angle pump motor pulling arm reversing device

A reversing device, isometric technology, applied in steering mechanism, transportation and packaging, non-deflectable wheel steering, etc., can solve the problems of unintegrated pump and motor, large volume and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

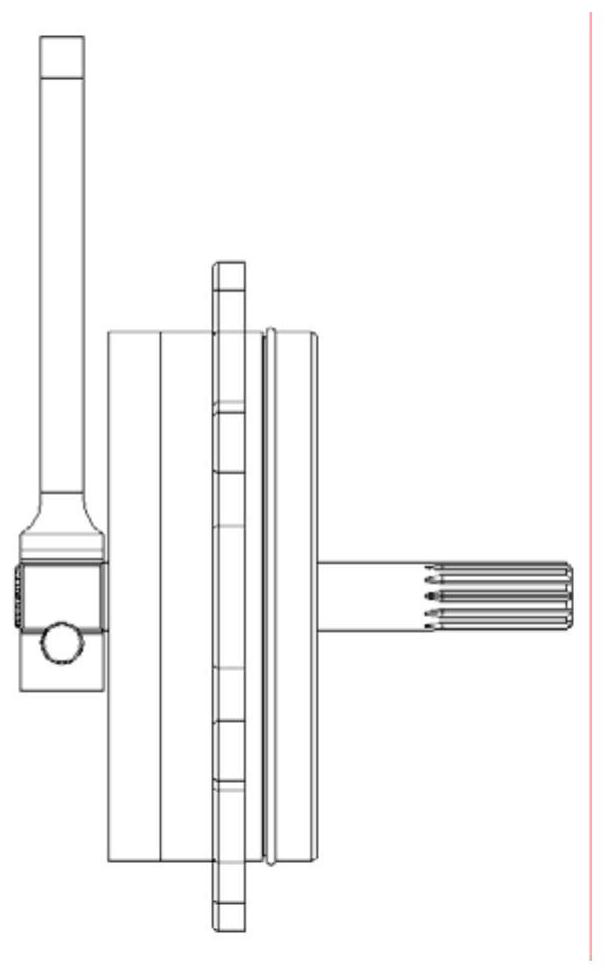

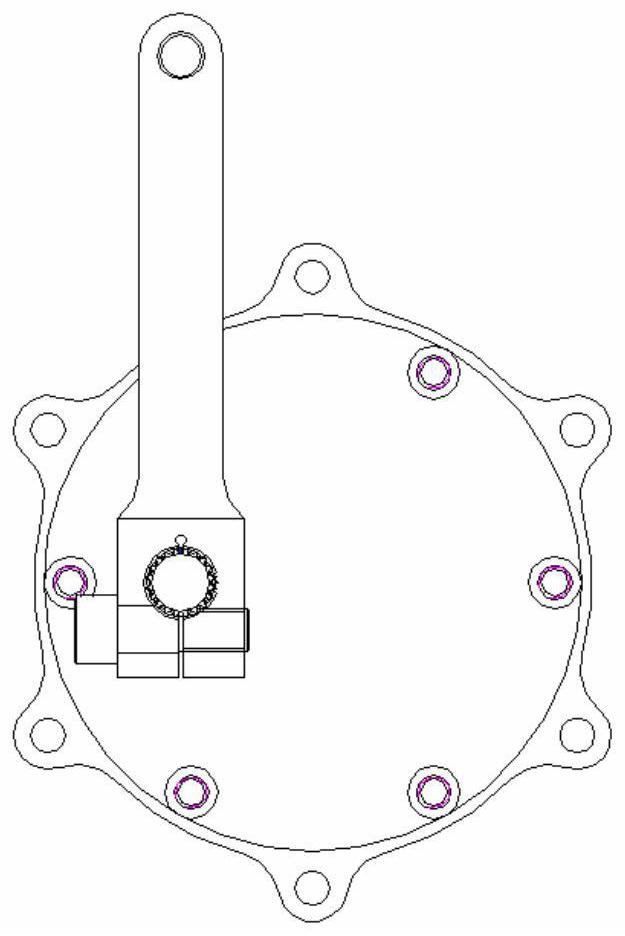

[0034] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] When the same type of pump motor product is applied to the comprehensive transmission of tracked vehicles with different layouts such as front and rear, there will be a problem that the rotation direction of the tracked vehicle is inconsistent with the rotation direction of the steering wheel. In the past, it was necessary to change the design of the control valve inside the pump motor to solve the problem of reversing. Not only the workload was heavy, but also the changed pump motor could not be unified, and the cost of manpower and material resources was increased. Using the traditional reversing mechanism, the structure is too complicated, the volume is large, and it is not easy to install on the integrated tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com