Nickel-based alloy-coated oil-suction polished rod with high-toughness clamping section and processing method thereof

A technology for sucking polished rods and nickel-based alloys, which is applied in metal material coating processes, coatings, drill pipes, etc., and can solve problems such as difficulty in effectively solving polished rod fractures and limited improvement in the service life of polished rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

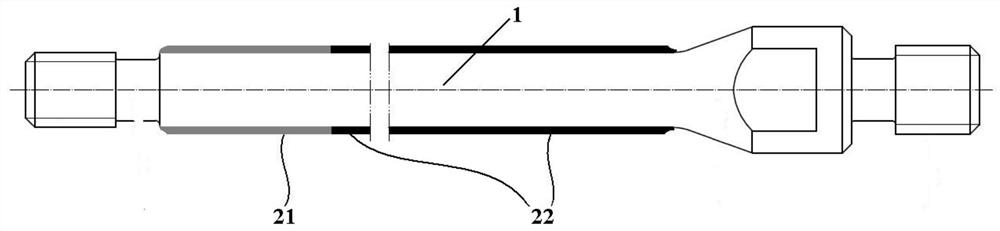

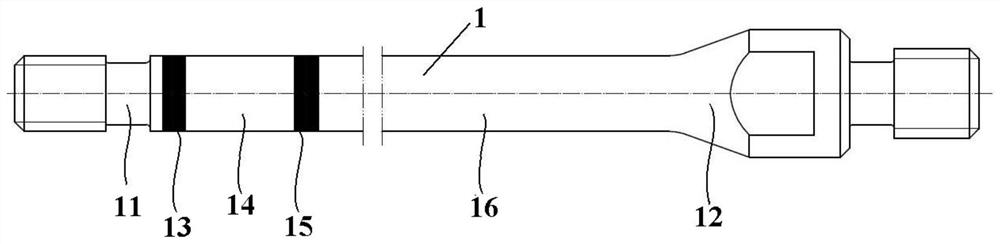

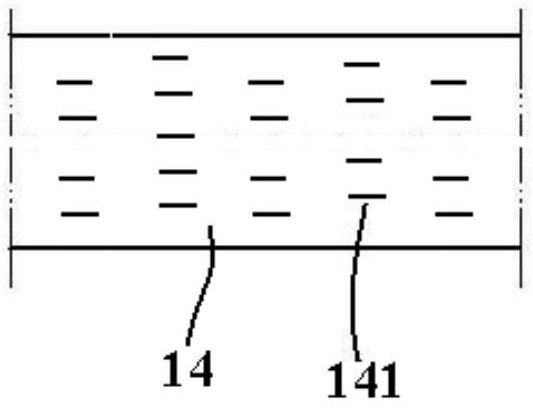

[0032] seefigure 1 with figure 2 According to the nickel-based alloy coated oil pumping rod with high toughness clamping section provided by the present invention, it comprises a base material 1 and an alloy coating positioned on the surface of the base material, the base material 1 is a long straight round rod, One end is an upset end 12, and the other end is an unupset end 11. Starting from the unupset end 11, the substrate 1 sequentially includes a first transition section 13, a clamping section 14, a second transition section 15 and a rod body 16 , the clamping section 14 of the substrate 1 is 1 to 3 meters long, and the first transition section 13 and the second transition section 15 are 0.1 to 0.5 meters long; the alloy coating includes a high-nickel tough composite coating 21 and a nickel-based self-fluxing alloy coating 22, the first transition section 13 and the clamping section 14 of the substrate 1 are prepared with the high-nickel tough composite coating 21, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com