Screw compressor automatic loading and unloading device and its control method, screw compressor

A screw compressor and control method technology, applied in the field of compressors, can solve problems such as oil circuit leakage and oil pressure instability, and achieve the effects of reducing sealing requirements, adjusting precision, and avoiding lubricating oil leakage and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

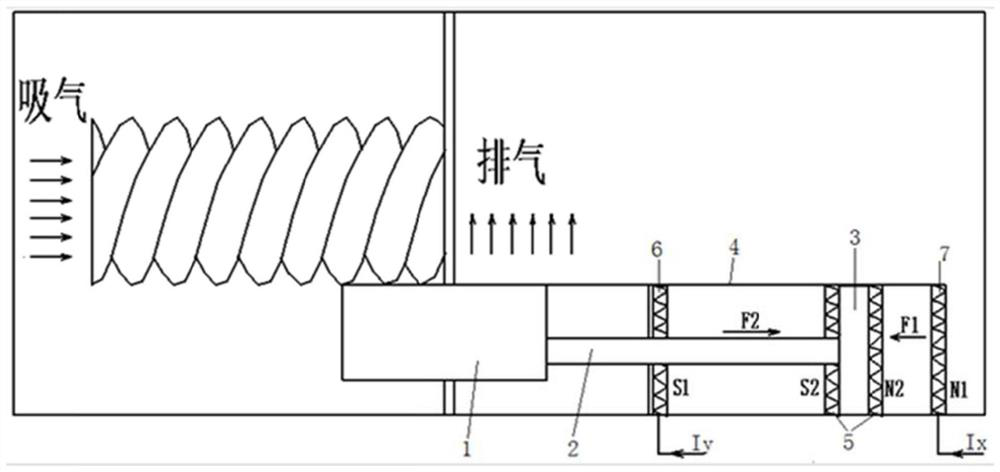

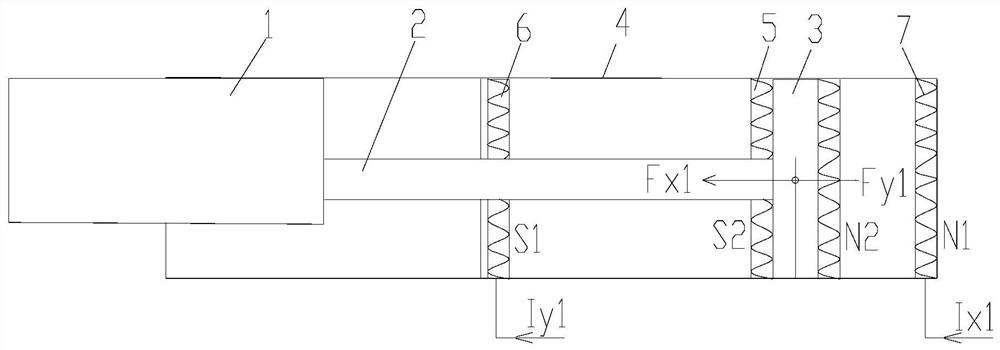

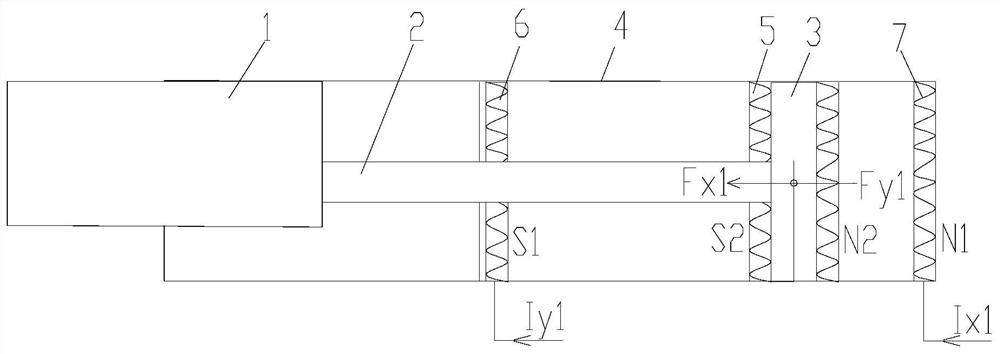

[0047] see in conjunction Figure 1 to Figure 4As shown, according to the embodiment of the present application, the screw compressor automatic loading and unloading device includes a slide valve 1 and an electromagnetic adjustment device, the drive end of the slide valve 1 is provided with a transmission unit, and the electromagnetic adjustment device includes a first drive part and a second drive part , the transmission unit includes a guide part and a transmission part, one end of the transmission part is drivingly connected with the spool valve 1, and the guide part is used to cooperate with the transmission part to limit the direction of force exerted by the transmission part on the spool valve 1, and the first drive part is fixed to the transmission part Connected, the second driving part cooperates with the first driving part to drive the transmission part to move, so as to adjust the sliding position of the slide valve 1 .

[0048] This application uses an electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com