Loading and unloading control system based on electromagnetic locating

A control system and electromagnetic positioning technology, applied in the field of compressor control, can solve the problems of unstable oil pressure in the piston cavity, inability to stabilize the sliding valve, oil circuit leakage, etc., to avoid frequent loading and unloading, avoid abnormal protection, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

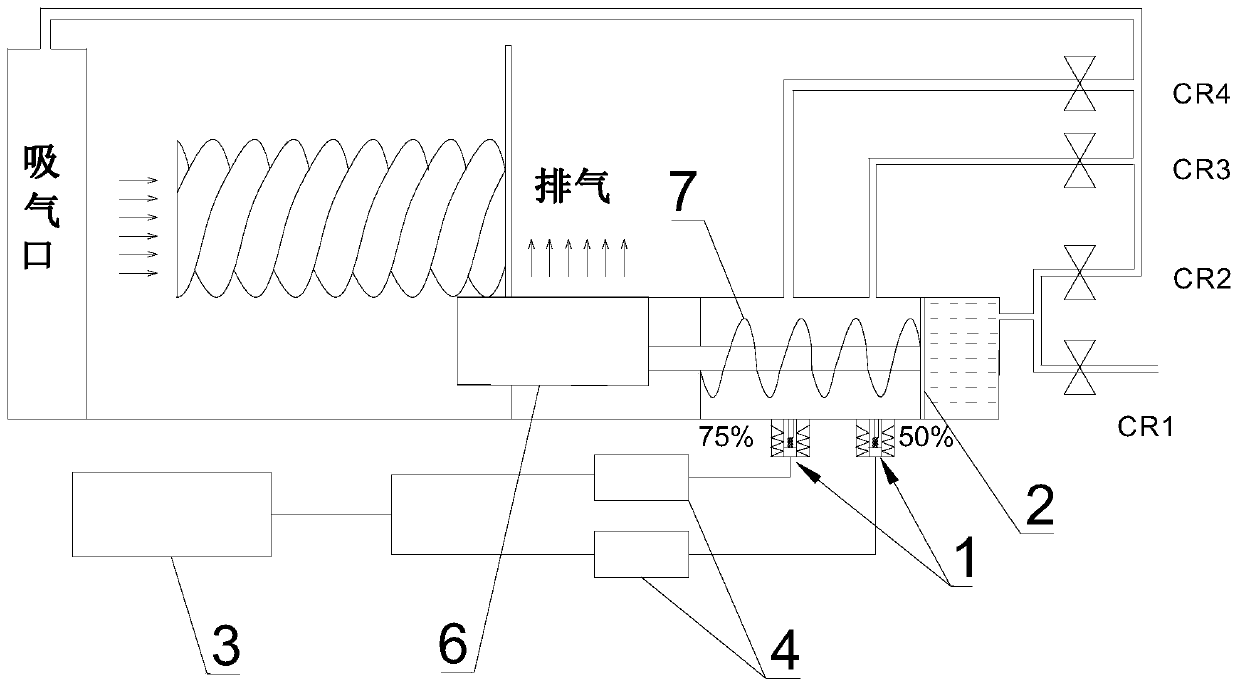

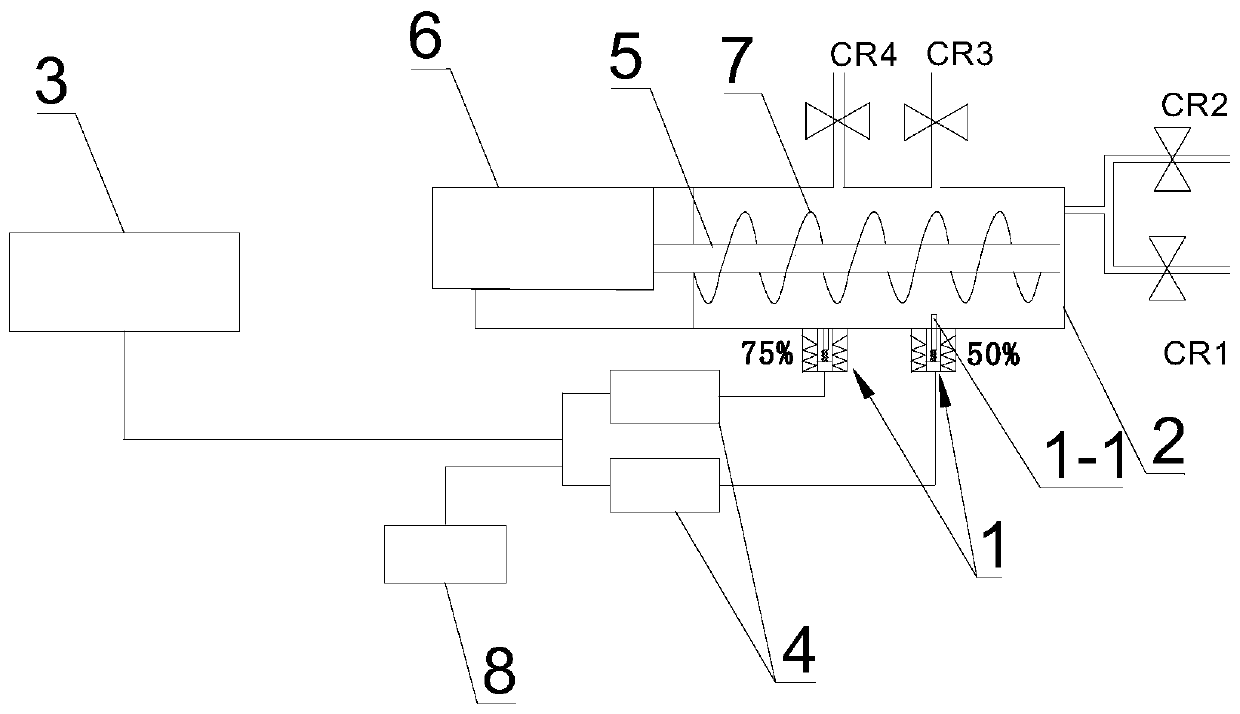

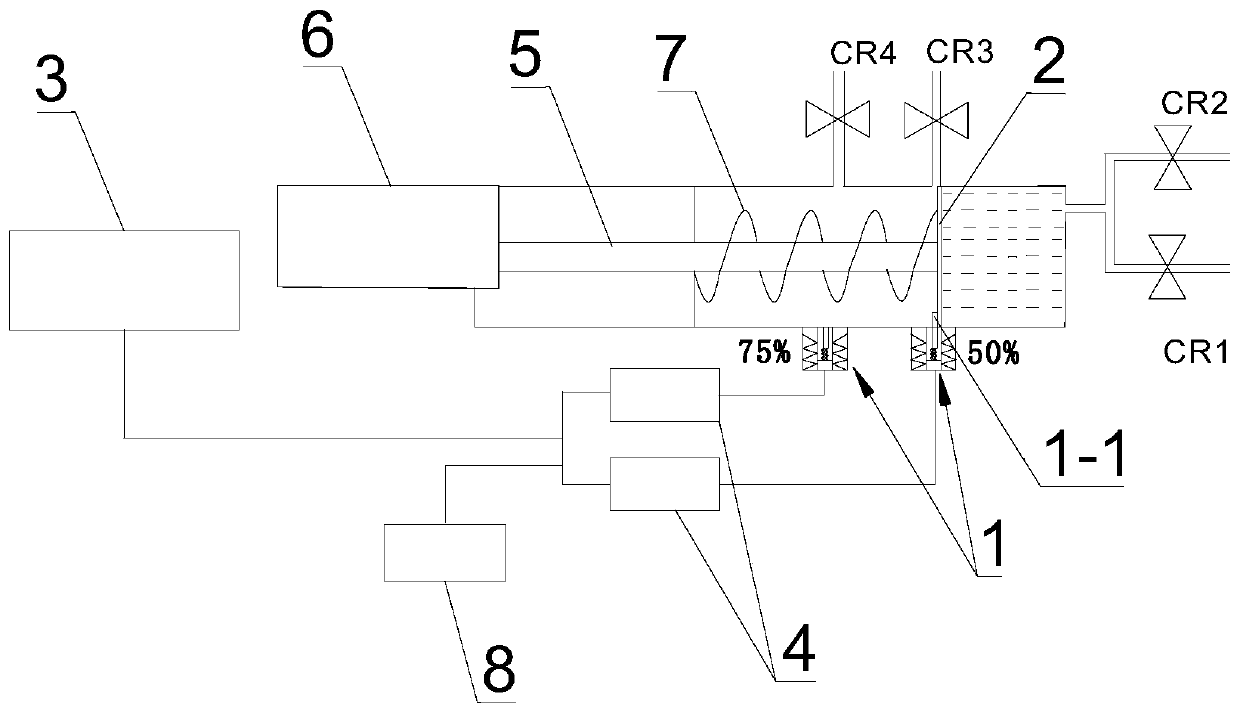

[0027] see Figure 1-6 , the loading and unloading control system based on electromagnetic positioning in this embodiment includes a plurality of electromagnetic limit devices 1 for positioning the piston 2 in the oil cylinder and an electric control module for controlling the positioning work. The limit device 1 includes a limit rod 1-1 and an electromagnetic drive mechanism, the electromagnetic drive mechanism is arranged on the outer wall of the oil cylinder, and is used to drive the limit rod 1-1 to perform telescopic movement toward the inner cavity of the oil cylinder, and the electromagnetic drive mechanism The driving direction of the driving mechanism is perpendicular to the moving direction of the piston 2 in the oil cylinder; in the state of loading and unloading, the limit rod 1-1 is respectively limited on both sides of the piston 2 . Specifically, there are two electromagnetic limiting devices 1, which are respectively set at positions representing 50% and 75% lo...

Embodiment 2

[0039] The difference from Embodiment 1 is that, with the load state 0 as the starting point and 100% as the end point, there are three electromagnetic limit devices 1 in this embodiment, which are respectively arranged on the representative 25%, 50% and 75% of the oil cylinder. position of the load.

Embodiment 3

[0041] Different from Embodiment 1, the load state is 0 as the starting point and 100% as the end point. In this embodiment, the number of electromagnetic limiting devices 1 can also be four, five or even more, depending on the application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com