High-engaging and low-noise screw compressor system and screw compressor

A screw compressor, low-noise technology, applied in the field of compressors, can solve problems such as poor automatic loading stability, poor compression effect of compressed gaseous refrigerant, poor meshing effect of male and female rotors, etc., to avoid frequent loading and unloading, improve overall performance, The effect of improving the meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

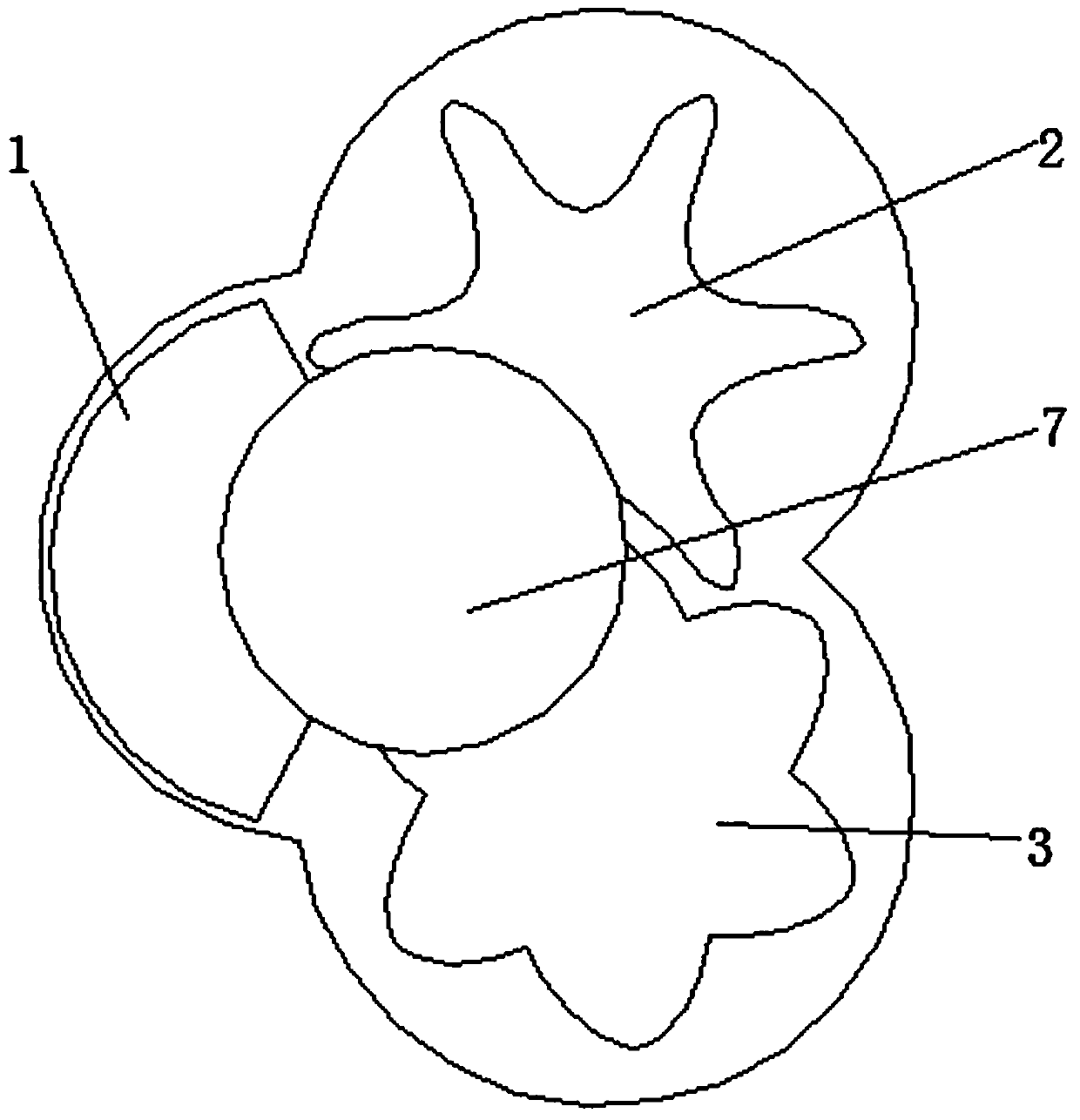

[0027] like Figure 1 to Figure 3 , a screw compressor system with high meshing and low noise, including a slide valve 1, a female rotor 2 and a male rotor 3, the female rotor 2 and the male rotor 3 are meshed and set up and down; the slide valve 1 is located at the One side of female rotor 2 and male rotor 3. The high meshing and low noise screw compressor system is mainly applied to screw compressors. The high meshing and low noise screw compressor system does not replace any parts, only by meshing the female rotor 2 and the male rotor 3 in the up and down direction; and then setting the slide valve 1 on one side of the female rotor 2 and the male rotor 3, Effectively improve the meshing effect between the female rotor 2 and the male rotor 3, improve the overall performance of the screw compressor, avoid the problem of frequent loading and unloading of the compressor caused by the instability of the slide valve 1, and help reduce the noise of the screw compressor .

[002...

Embodiment 2

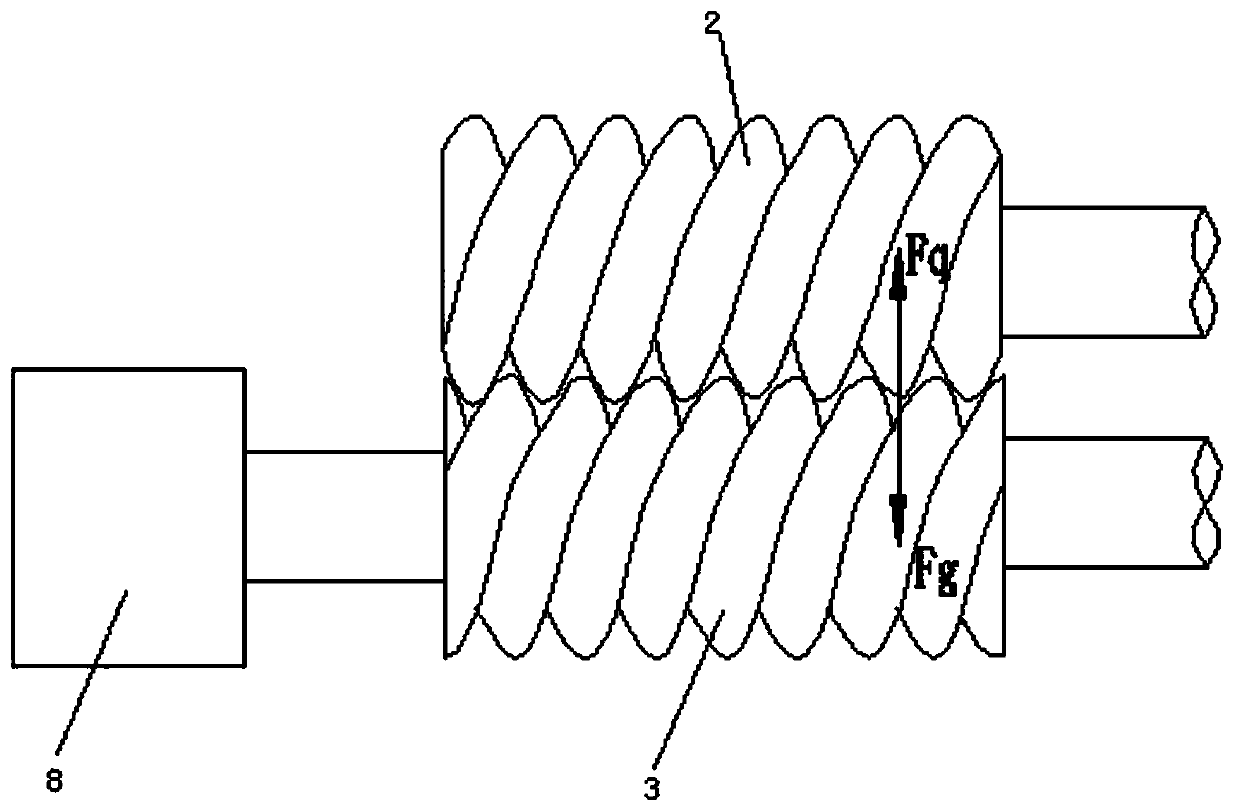

[0034] In Embodiment 2, the high-mesh and low-noise screw compressor system of this embodiment is basically the same as Embodiment 1, except that the female rotor 2 is located below the male rotor 3 . The positions of the female rotor 2 and the male rotor 3 have changed, the male rotor 3 is connected to the motor 8, and the motor 8 drives the male rotor 3 to rotate, and then drives the female rotor 2 to mesh with the male rotor 3 to complete other compression processes. In the process of meshing and compressing the gaseous refrigerant, the male rotor 3 is above the female rotor 2, and the male rotor 3 and the female rotor 2 are arranged up and down, and the common gravity Fg of the female rotor 2 and the male rotor 3 overcomes the impact of the compressed gas on the female rotor. The common reaction force Fq of the rotor 2 and the male rotor 3 makes the meshing effect of the female rotor 2 and the male rotor 3 better, the amount of compressed gas is larger, and the compression ...

Embodiment 3

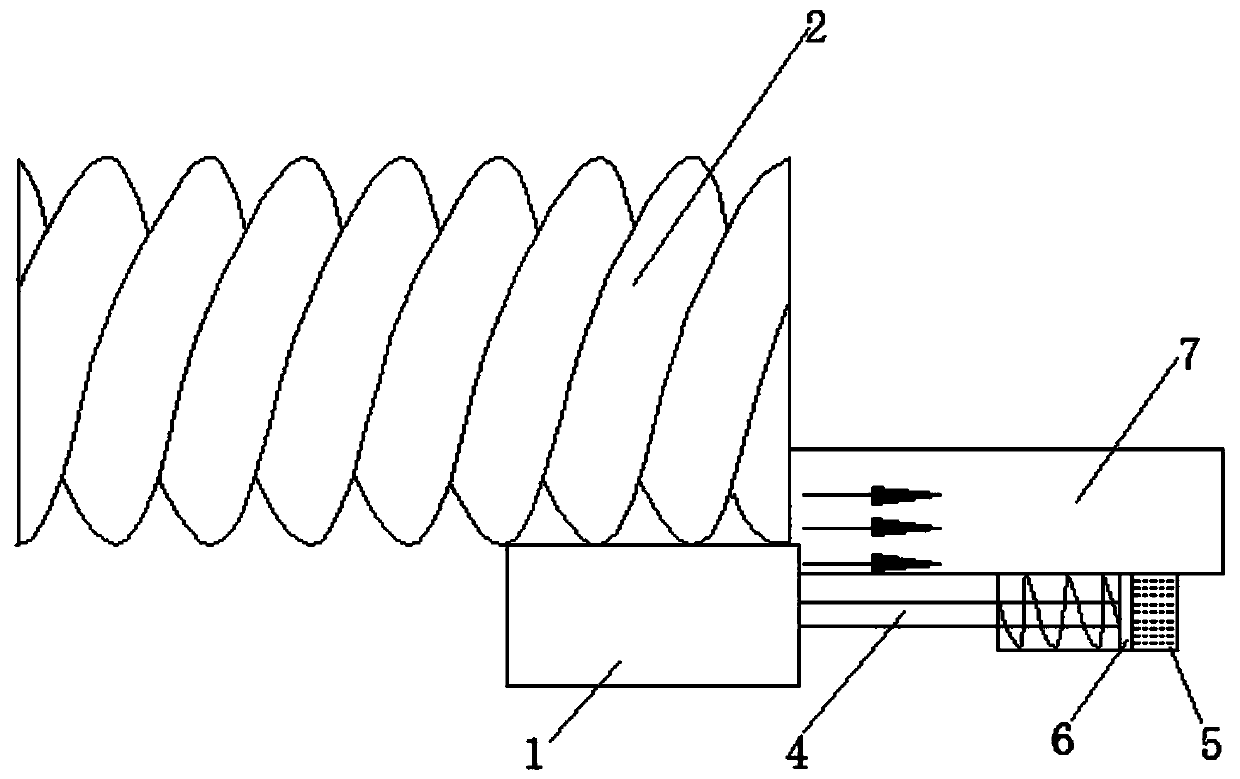

[0036] In Embodiment 3, the high-mesh and low-noise screw compressor system of this embodiment is basically the same as Embodiment 1, except that the slide valve 1 is located on the right side of the female rotor 2 and the male rotor 3 . The female rotor 2, the male rotor 3 and the slide valve 1 are arranged left and right, and the exhaust pipe 7 is arranged in parallel with the oil piston chamber 5. directly discharged. The gaseous refrigerant is directly discharged along the exhaust pipe 7, and the resistance in the straight pipe section is small, which effectively reduces the dynamic noise of the gaseous refrigerant, thereby achieving the purpose of effectively reducing the noise of the compressor; avoiding that the gaseous refrigerant first passes through the vertical pipe section of the exhaust pipe 7 It is discharged along the horizontal pipe section of the exhaust pipe 7, and the air flow vortex is easy to form at the corner of the pipe section of the exhaust pipe 7, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com