Magnetic bearing centrifugal compressor and controlling method thereof

A technology of centrifugal compressor and control method, which is applied in the direction of compressor, irreversible cycle compressor, pump control, etc. It can solve the problem of inability to adjust the gas leakage and control the size of the axial force, and the inability to adjust the clearance of the labyrinth shaft seal And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

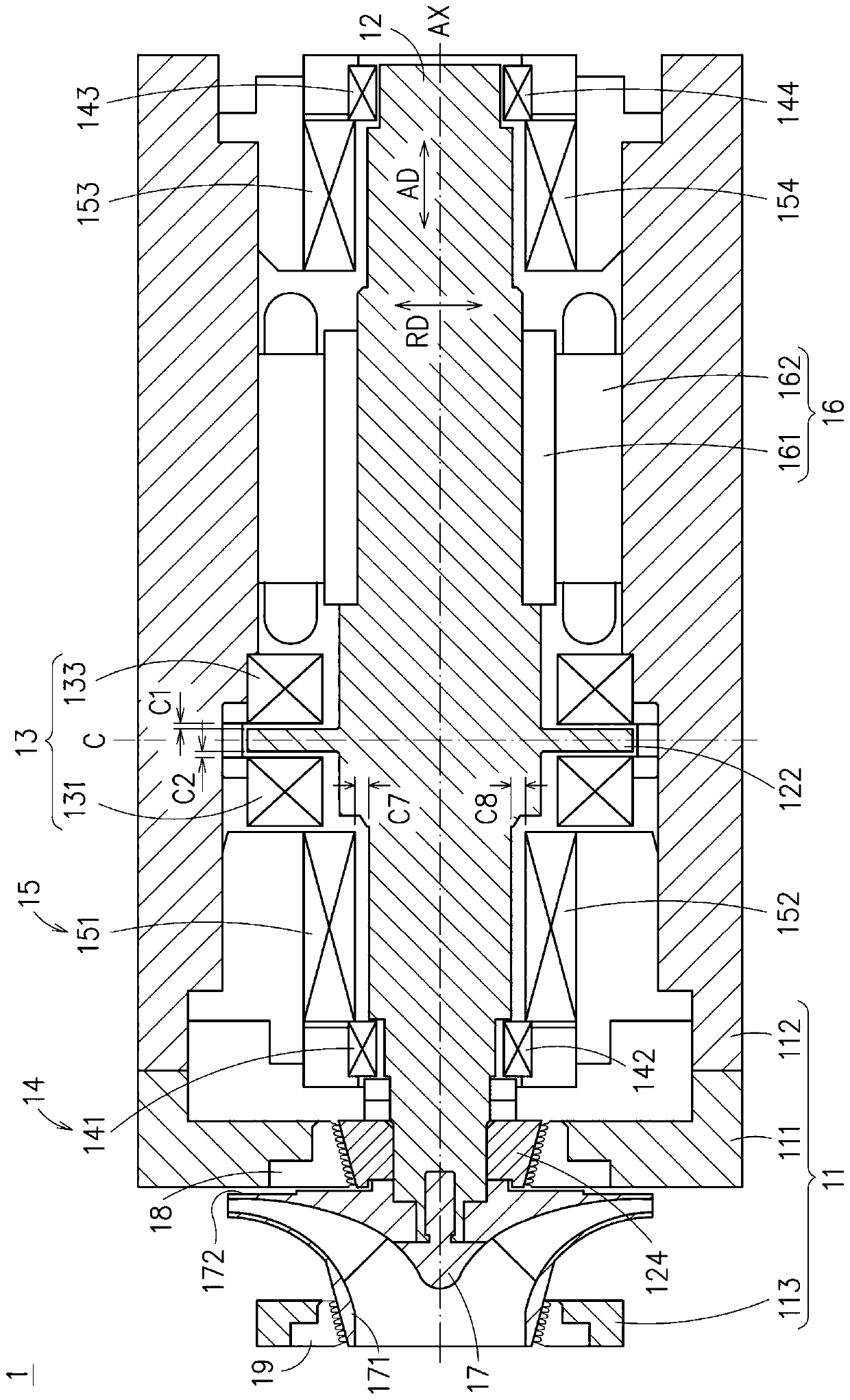

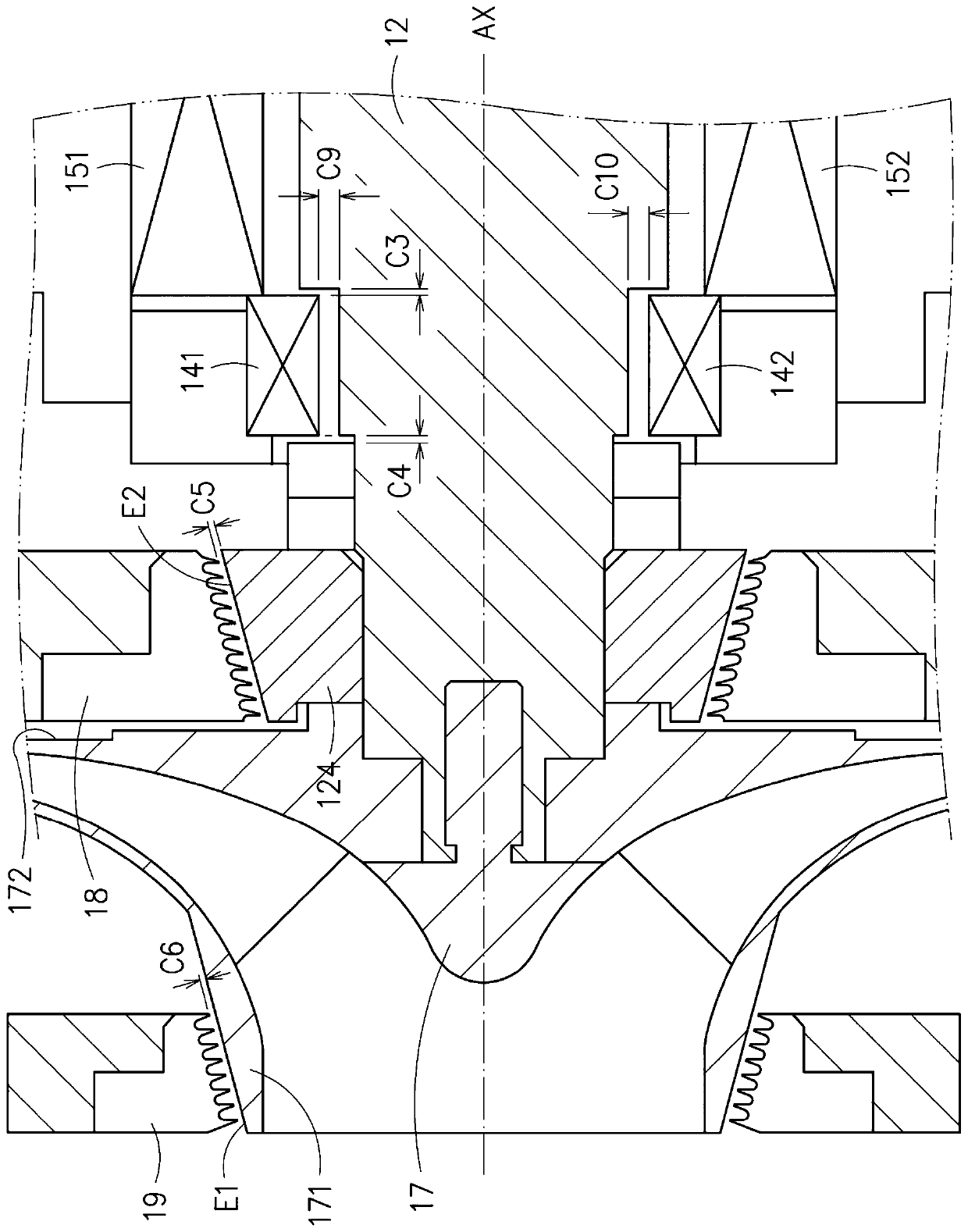

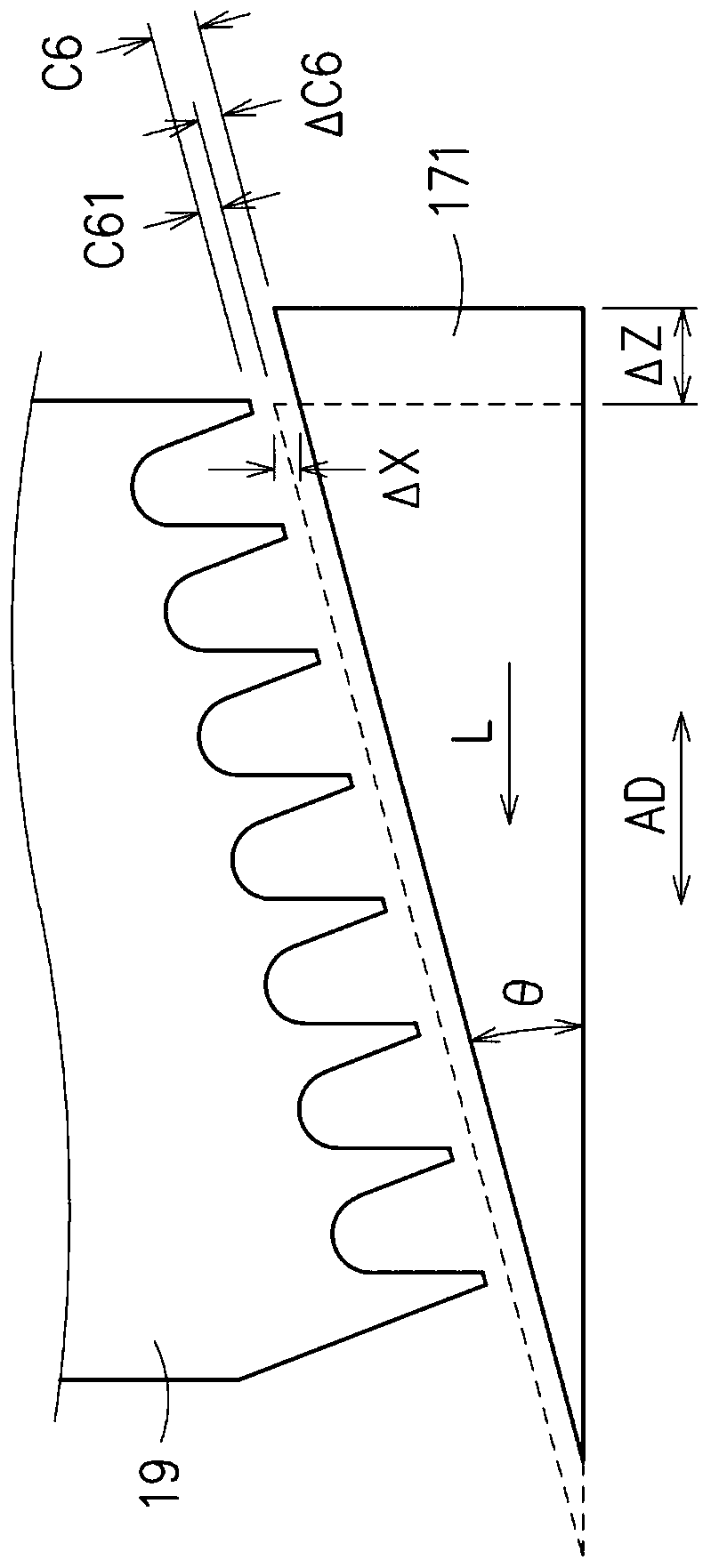

Embodiment Construction

[0076]The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention. It should be noted that, in the descriptions of the various embodiments, the descriptions of "upper / upper", "lower / lower", "front end / front" or "rear end / rear", "left" or "right" etc. This formula is described as a baseline, but other possible changes in direction are also included. In addition, the so-called "first", "second", "third", and "fourth" are used to describe various elements, and these elements are not limited by such terms. For the convenience and clarity of illustration, the thickness or size of each element in the drawings is exaggerated or omitted or shown in a rough manner, and the size of each element is not entirely its actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com