Dry hanging type wallboard installation structure

An installation structure, dry-hanging technology, applied in building construction, covering/lining, construction, etc., can solve the problems of uneven wall plate inclination, instability of dry-hanging system, many processes and costs, and reduce The effect of construction difficulty, improving construction efficiency and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

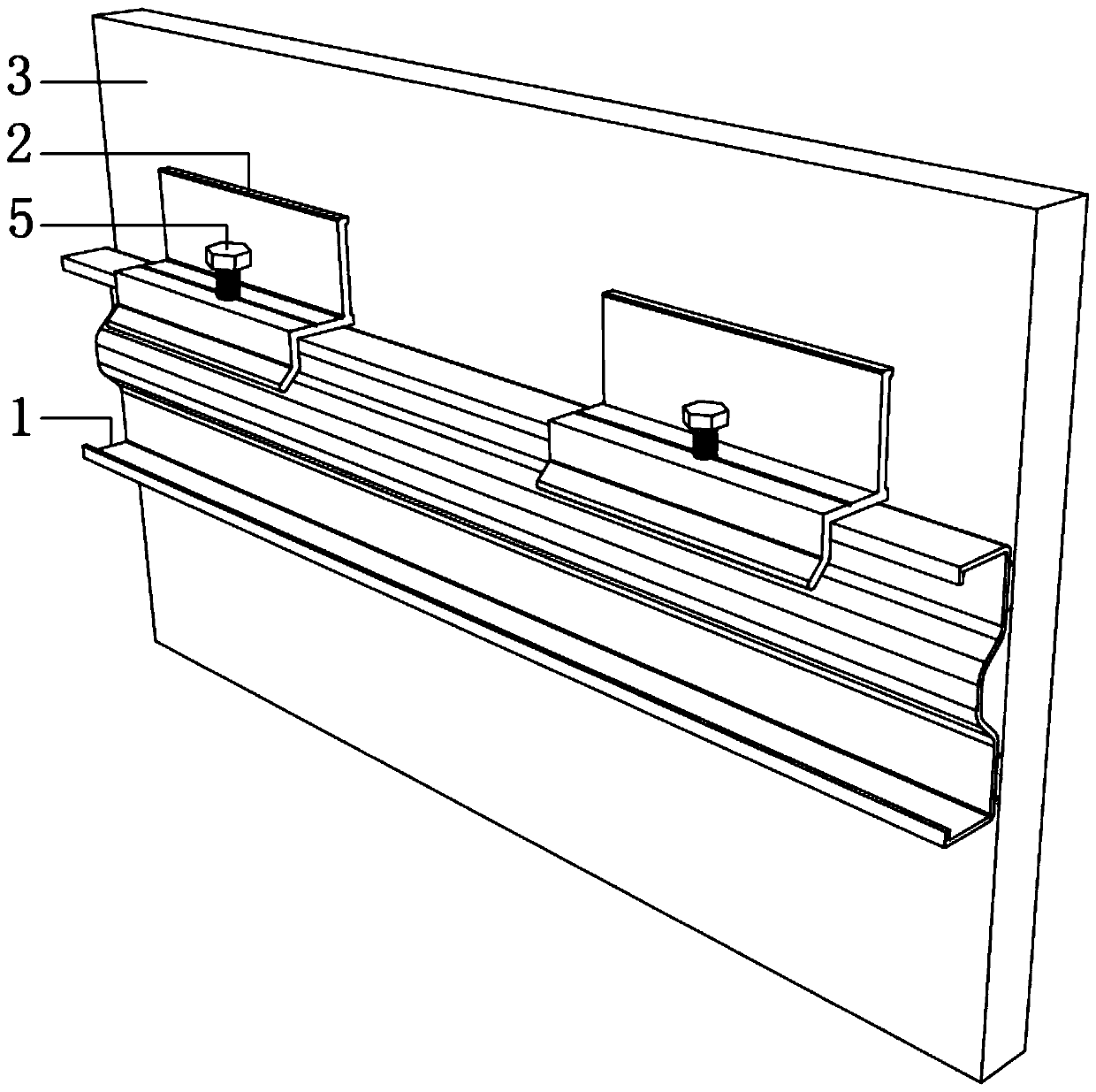

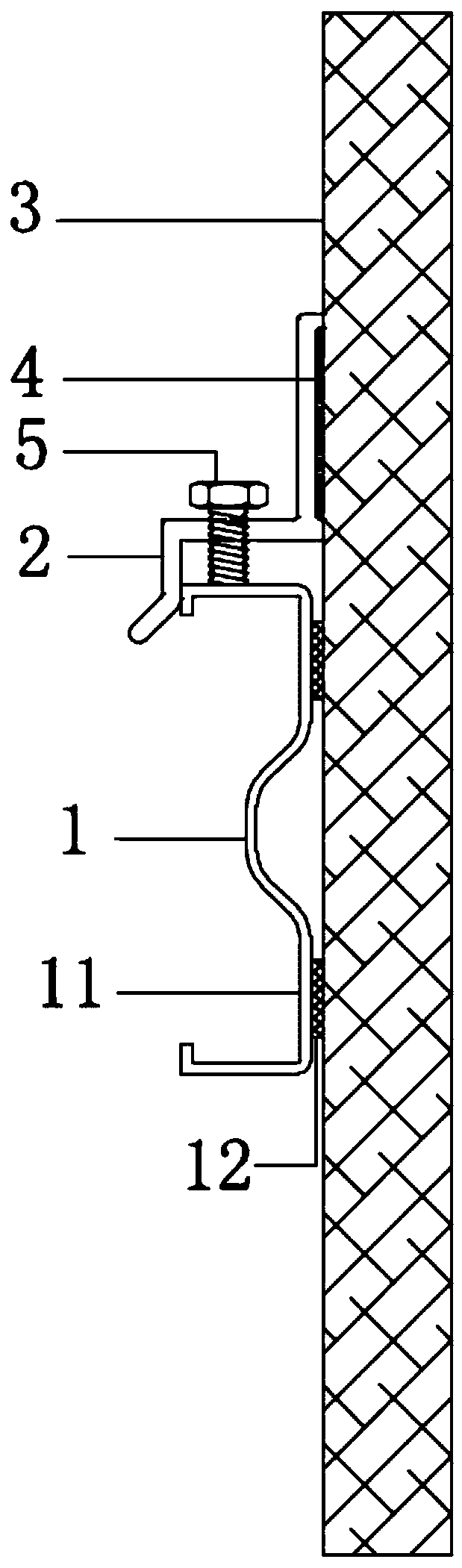

[0029] see Figure 1 to Figure 4 , the figure shows a dry-hanging wall panel installation structure provided by Embodiment 1 of the present invention, including a keel 1, a back hanger 2 and a decorative panel 3, the section of the keel 1 is M-shaped, and the opening direction of the keel 1 faces the wall surface, fixedly installed on the wall, the cross-section of the back hanging part 2 is Z-shaped, the back hanging part 2 includes a connecting part 21 with an L-shaped cross-section and a clamping part 22 with an L-shaped cross-section, and the connecting part 21 is perpendicular to the clamping part 22 , the veneer 3 is bonded to the connecting portion 21 through the adhesive material 4, and the whole formed by bonding the hanging part 2 and the veneer 3 is clamped on the keel 1 through the clamping part 22, and the clamping part 22 is provided with at least one Adjusting screw 5 , the adjusting screw 5 runs through the clamping portion 22 , and the bottom end is against th...

Embodiment 2

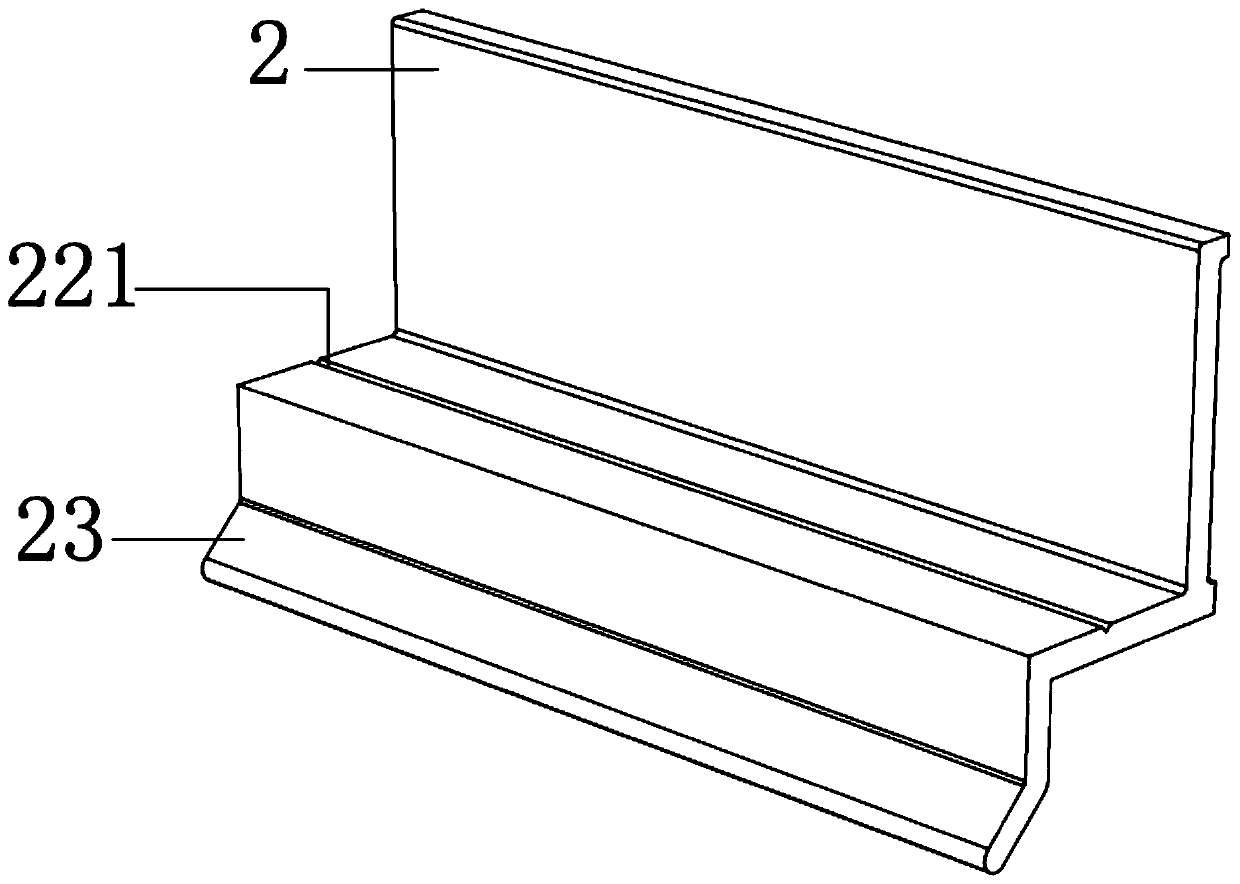

[0039] see Figure 1 to Figure 4 , the figure shows a dry-hanging wall panel installation structure provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the clamping part 22 is provided with first grooves 221 , and the first grooves 221 are arranged along the length direction of the back hanger 2 . The cross section of the second groove 2 is triangular.

[0040] Multiple adjustment screws can be set on the back hanger to improve the adjustment effect of the installation height of the veneer. In order to ensure the adjustment effect, it is necessary to make multiple adjustment screws on the same straight line. The surface of the clamping part is provided with a first groove. in the first groove. In order to further ensure that the self-tapping screws can be on the same straight line and perpendicular to the keel during installation, without skewing and affectin...

Embodiment 3

[0042] see Figure 1 to Figure 4 , the figure shows a dry-hanging wall panel installation structure provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following technical solutions as improvements: the connecting part 21 The surface of the second groove 211 is provided, and the adhesive material 4 is filled in the second groove 211 .

[0043] In order not to make the adhesive material affect the flatness of the installation of the veneer and the back hanger, the surface of the connecting part is provided with a second groove, and the adhesive material is filled in the second groove, which can also increase the amount of MS glue and improve Adhesive effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com