Bending device for water pipe processing

A technology for a bending device and a water pipe, which is applied in the field of bending devices for water pipe processing, can solve the problems of water pipe bending, water pipe falling off, water pipe sliding, etc., and achieves the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

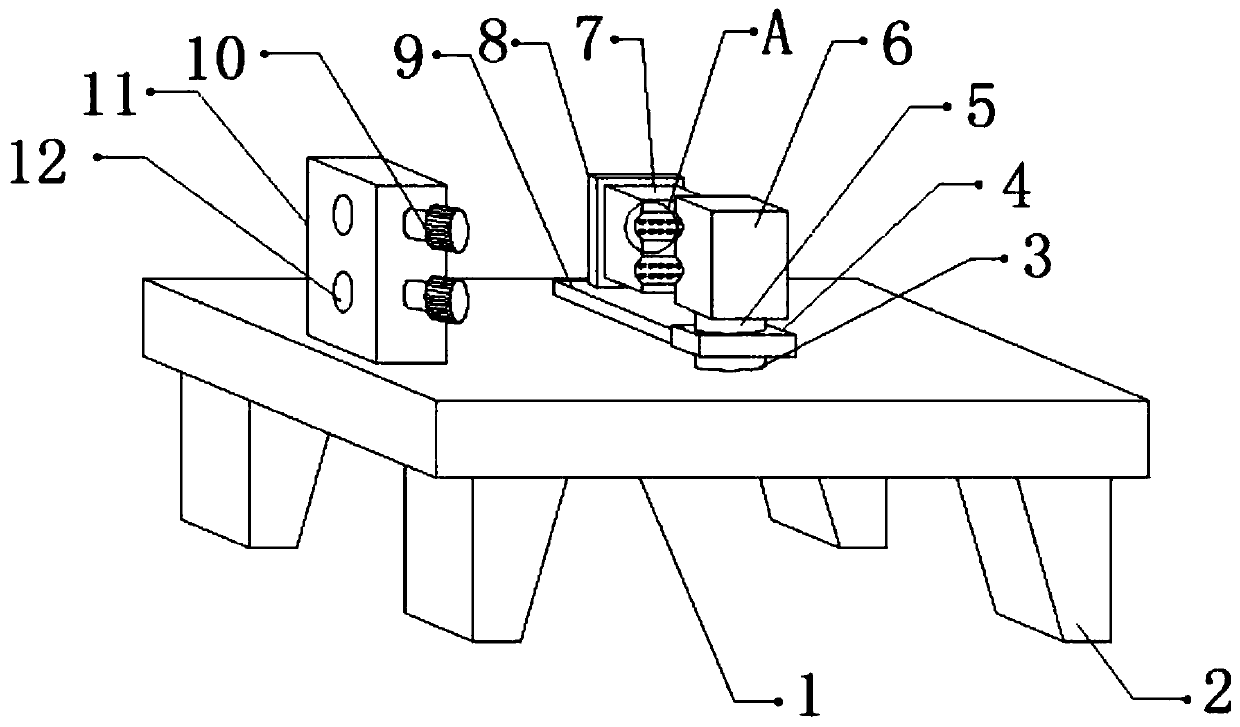

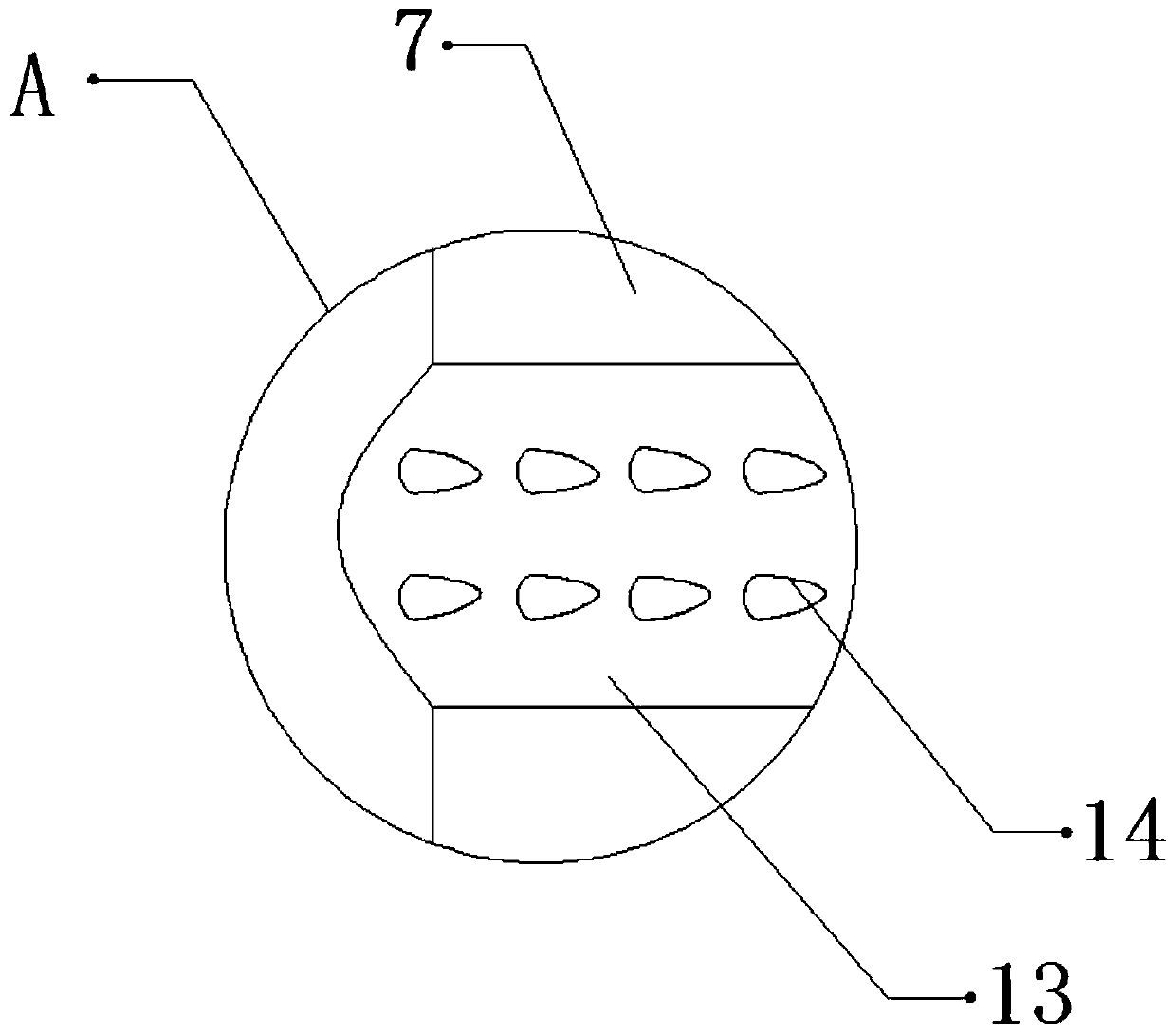

[0029] refer to Figure 1-4 , a bending device for water pipe processing, comprising a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected to a rotating shaft 3 through bearing rotation, and the top outer wall of the rotating shaft 3 is connected to a fixed block 4 by bolts, and the top of the fixed block 4 The outer wall is connected with a fixed shaft 5 by bolts, and the top outer wall of the fixed shaft 5 is connected with a bending mechanism 6 by bolts, and the outer wall of one side of the fixed block 4 is connected with a connecting plate 9 by bolts, and one side of the outer wall of the top of the connecting plate 9 passes through Bolts are connected with a support plate 8, and one side of the outer wall of the support plate 8 is connected with an electric telescopic rod 18 by bolts, and one side of the outer wall of the electric telescopic rod 18 is connected with a splint 7 by bolts, one side of the splint 7 and the bending mechanism 6 Limiti...

Embodiment 2

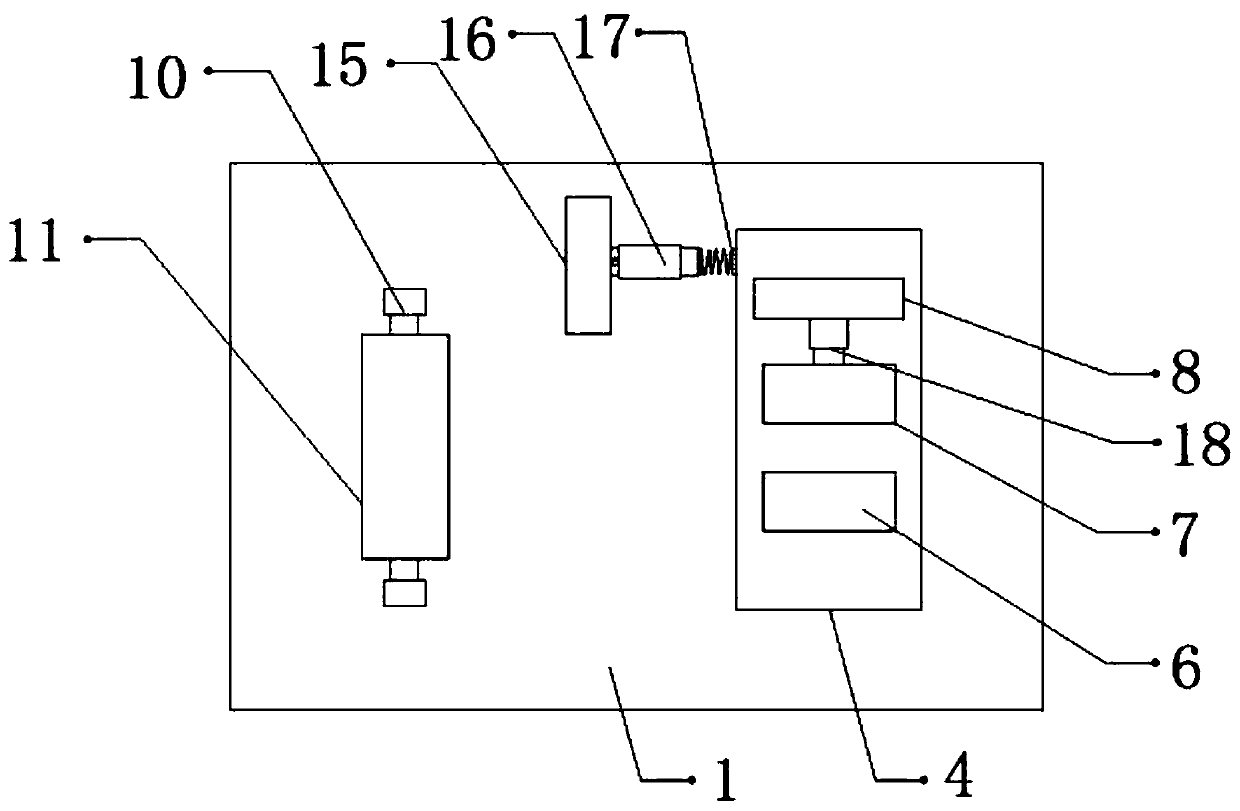

[0038] refer to Figure 5-6 , a bending device for water pipe processing. Compared with Embodiment 1, the outer walls of the opposite sides of the two restraining plates 19 are provided with a plurality of protruding teeth 20, and both the protruding teeth 20 and the constraining plates 19 are flexible. The material can cover the other end of the water pipe so as to protect the water pipe and prevent the surface of the water pipe from being damaged due to external force when the water pipe is bent. Slipping occurs inside.

[0039] Working principle: When in use, place the water pipe inside the limit groove 13 through the jack 12, start the electric telescopic rod 18, and the electric telescopic rod 18 will drive the splint 7 to move, so that the splint 7 can clamp and fix the water pipe, and pass The convex teeth 14 can increase the friction between the water pipe and the limiting groove 13, so as to fix the water pipe and prevent the water pipe from slipping from the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com