Press machine offcut automatic cutting device

An automatic cutting and press technology, applied in the field of stamping equipment, can solve the problems of irregular shapes of scraps, manual collection of side scraps increases labor intensity, inconvenient recycling, etc., and achieves the effect of consistent cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

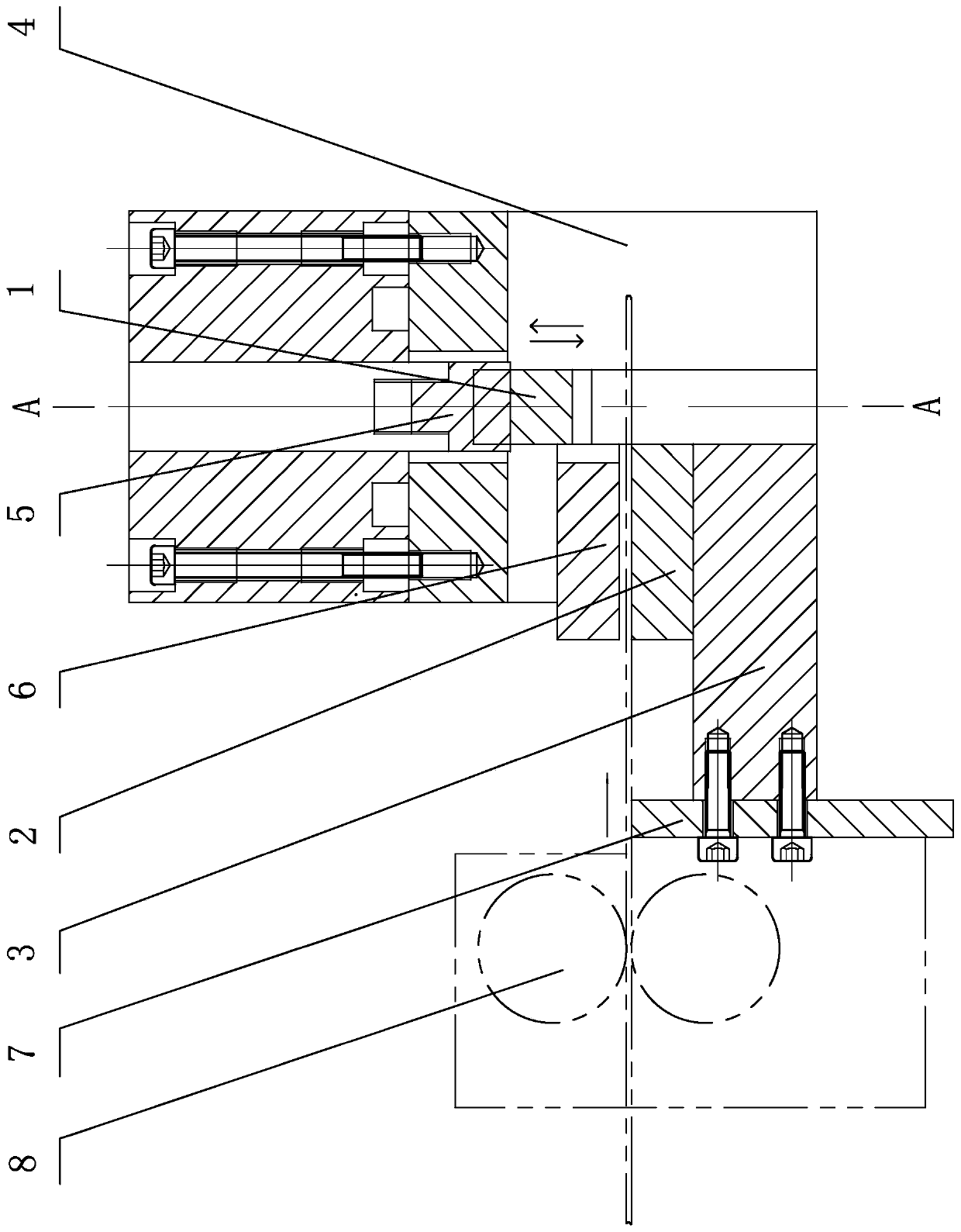

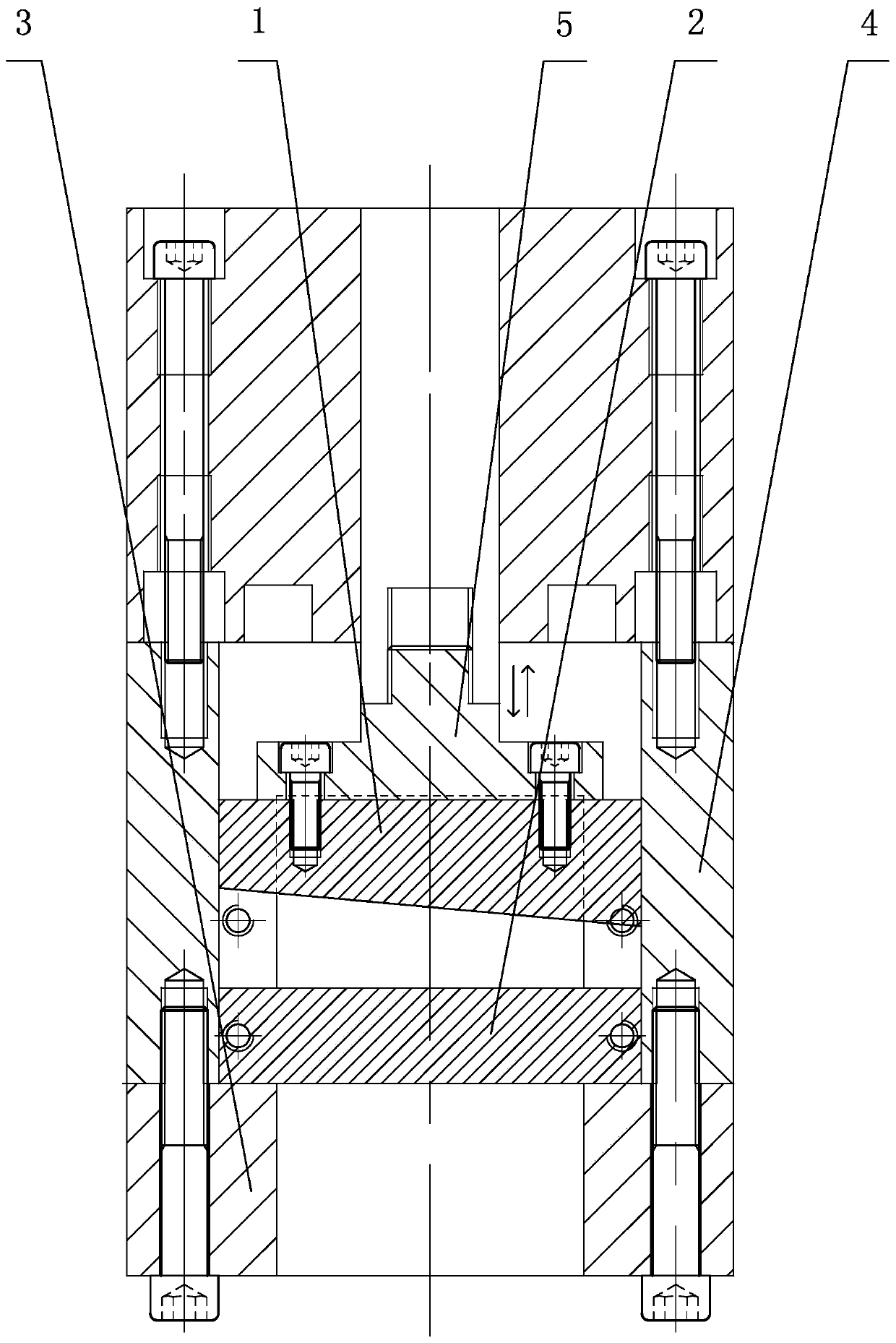

[0019] The technical solution of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

[0020] The automatic cutting device for edge material of the press of the present invention includes a shearing mechanism arranged on the rear side of the discharge end of the press. The shearing mechanism is provided with a mechanical roller feeder 8, and the upper part of the mechanical roller feeder 8 , The bottom roller clamps and pulls the stamping edge material of the press with the same length step distance and feeds it between the upper movable knife 1 and the lower fixed knife 2 of the shearing mechanism for cutting, such as figure 1 Shown.

[0021] The press is an open fixed table press with a counter, and is equipped with an electronic cam controller or an adjustable mechanical cam controller, and the cam in the controller indicates the punching position of the die.

[0022] The shearing mechanism includes an upper movable knif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap