A friction type sugarcane automatic peeling and cutting machine

A technology of friction and cutting machine, which is applied in the fields of vegetable or fruit peeling, metal processing, food science, etc., which can solve the problems of low efficiency and physical exertion, and achieve the effect of high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

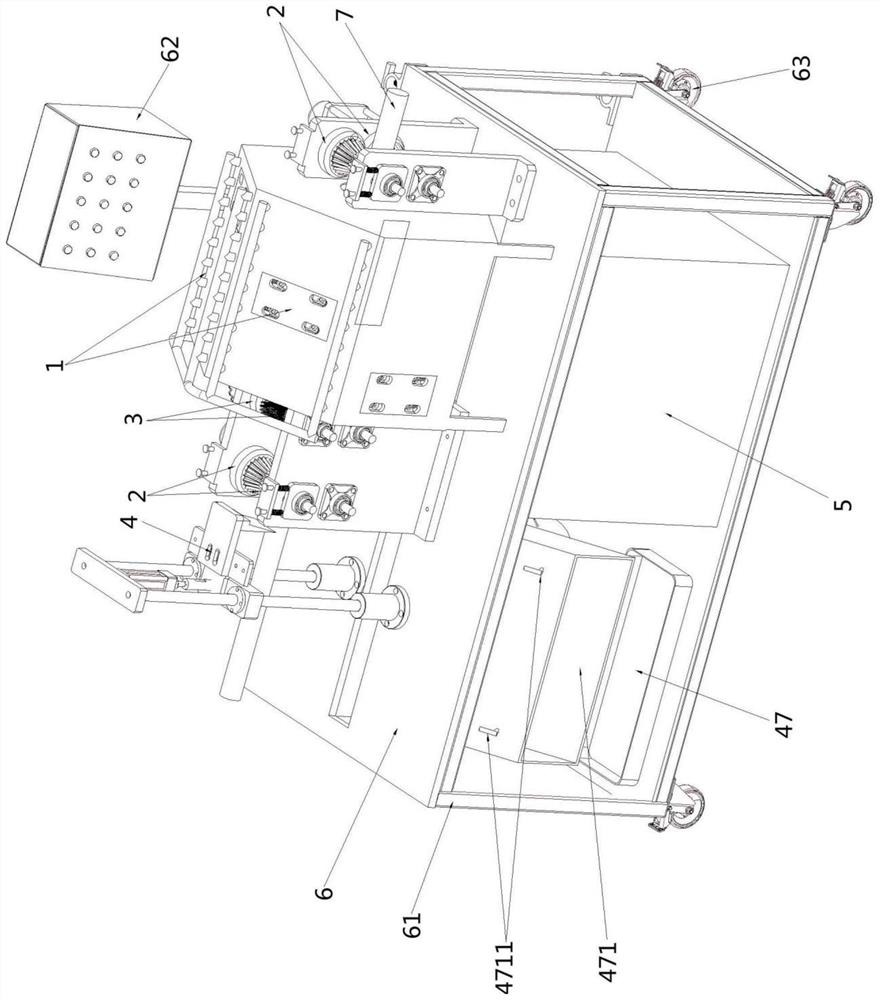

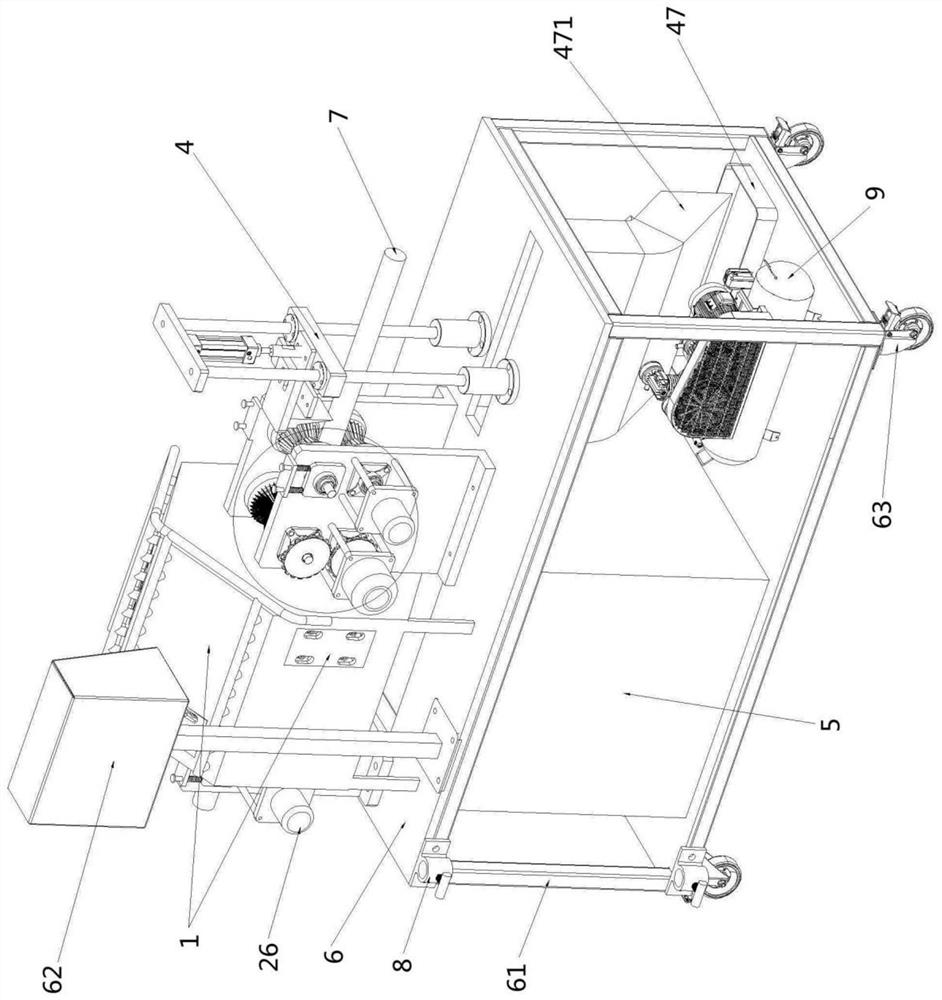

[0040] See attached manual figure 1 -20, a friction type sugarcane automatic peeling and cutting machine, characterized in that: the friction peeling mechanism, the front end and the rear end of the friction peeling mechanism, which are installed on the platform plate of the frame, are all provided with a conveying mechanism;

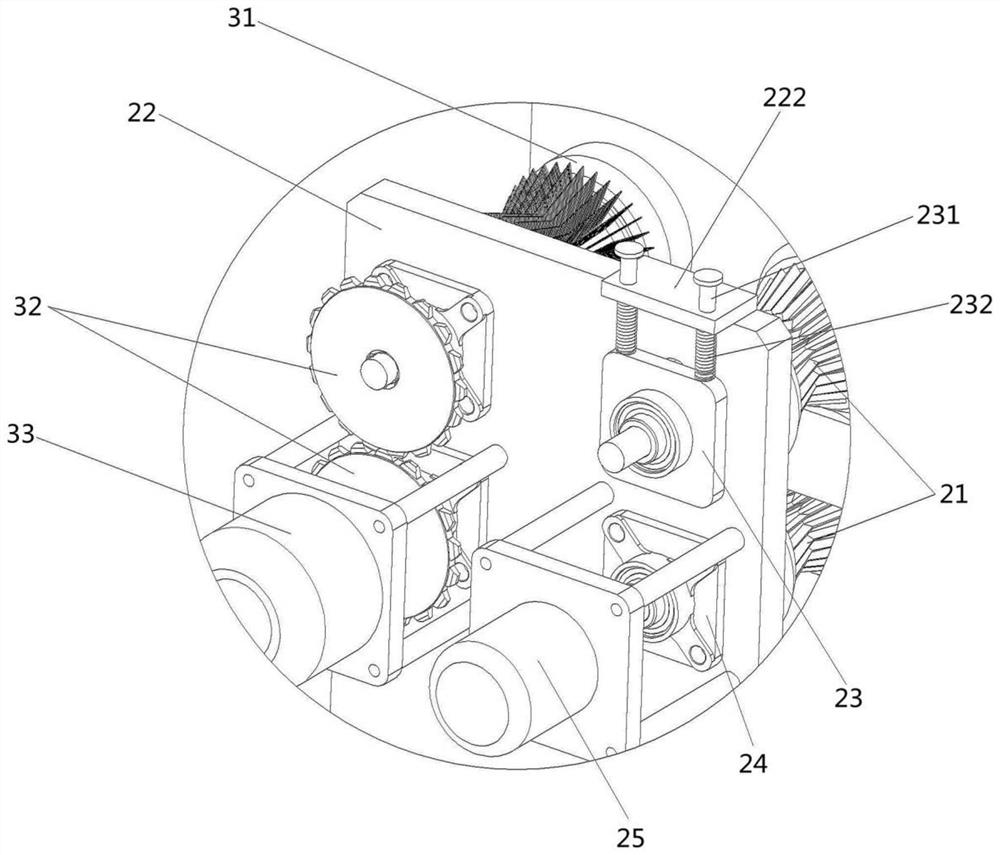

[0041] The friction peeling mechanism includes a fixed blowing hood fixed on the platform plate and a friction peeling component installed inside. The fixed blowing hood is a six-sided cavity structure, and each side is provided with a friction peeling component. Installation holes, 3 sets of symmetrically arranged friction-type peeling components can quickly remove the epidermis of sugar cane in 360 degrees. There are a plurality of blowing holes evenly distributed on both sides of the air hood. Each row of blowing holes is connected with a blowing pipe, and one end of the plurality of blowing pipes is connected to each other. The high-pressure air at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap