Forage grass cutting equipment

A kind of equipment and section cutting technology, which is applied in the direction of cutting equipment, agricultural machinery and implements, applications, etc., and can solve the problems of low degree of automation and uneven section cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

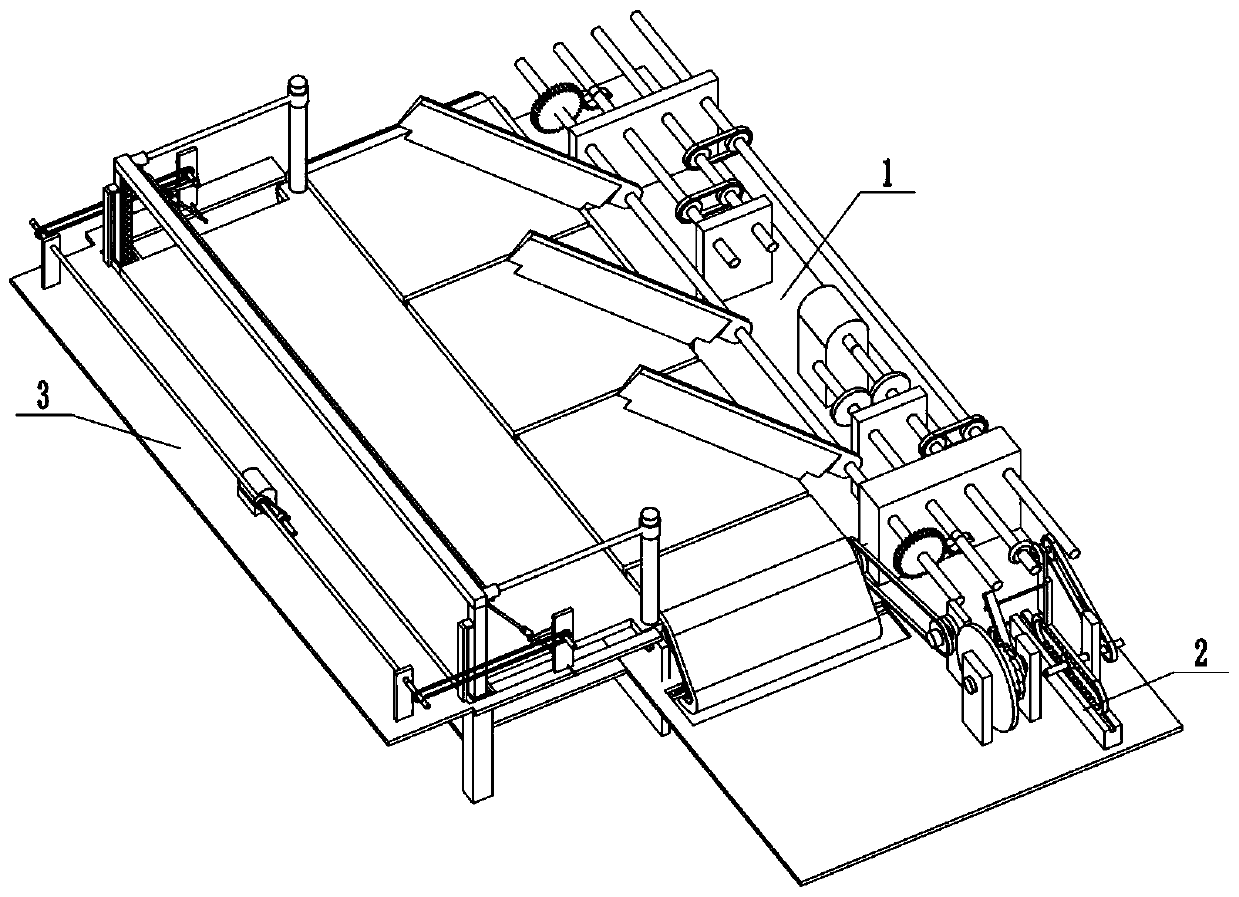

[0029] Combine below Figure 1-15 Describe this embodiment, a kind of forage cutting equipment, including guillotine cutting assembly 1, conveying device 2 and feeding assembly 3, described guillotine cutting assembly 1 is connected with conveying device 2, and feeding assembly 3 is connected with conveying device Device 2 is connected.

specific Embodiment approach 2

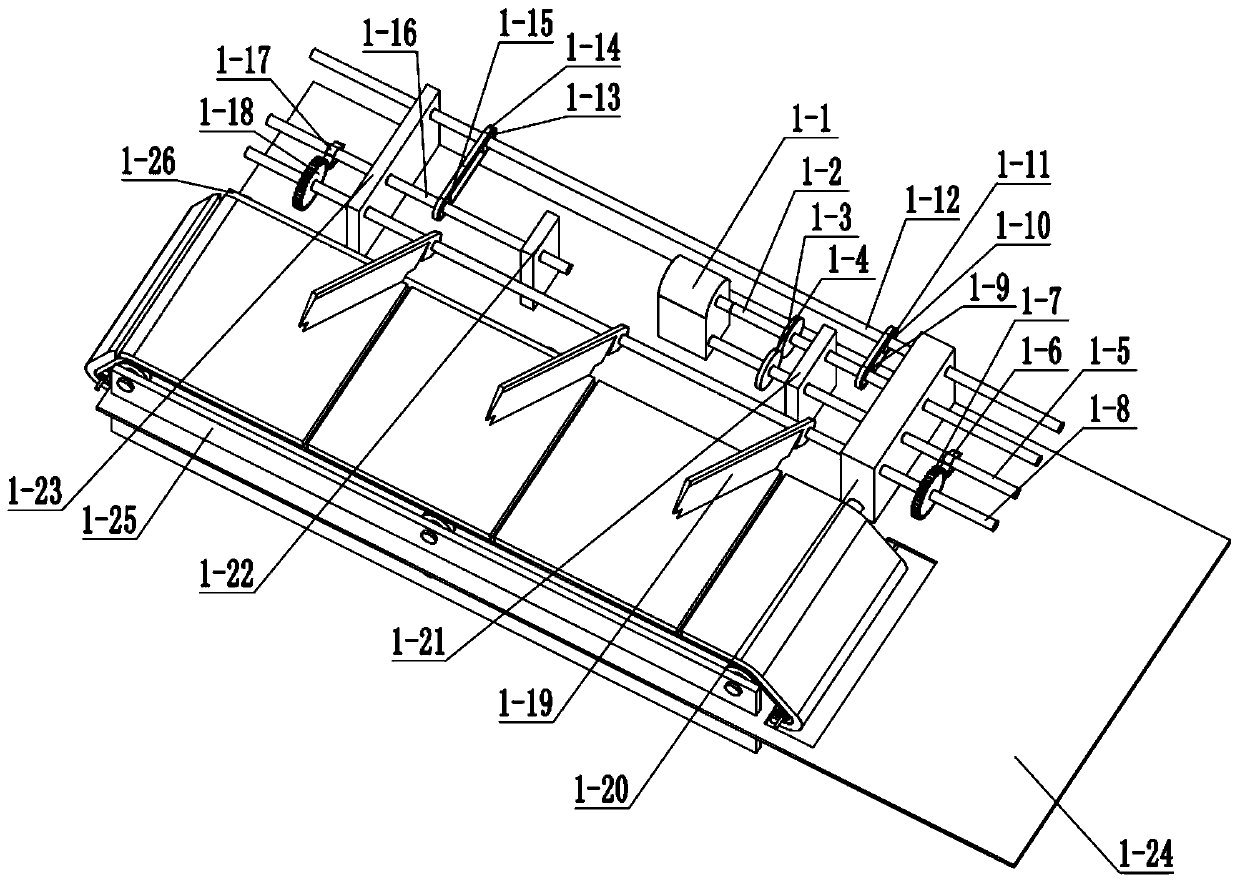

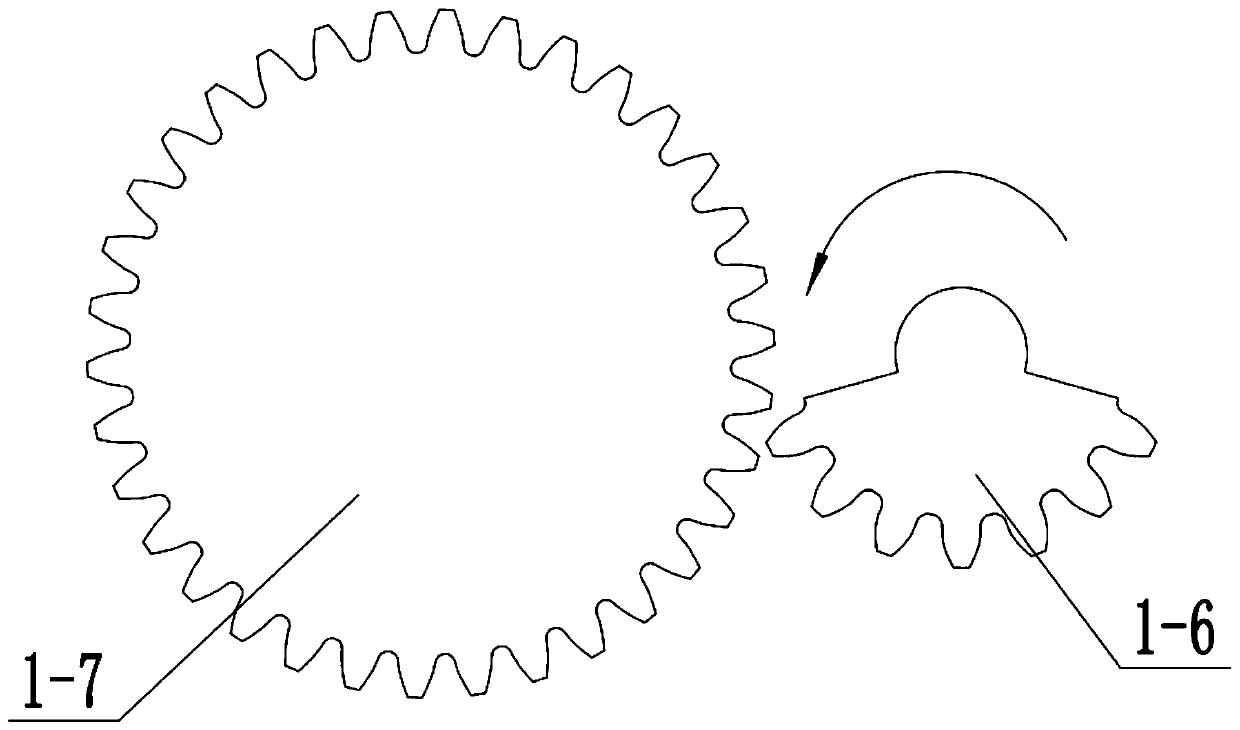

[0031] Combine below Figure 1-15 This embodiment will be described. This embodiment will further explain Embodiment 1. The guillotine assembly 1 includes a guillotine motor 1-1, a guillotine motor shaft 1-2, a gear I1-3, and a gear II1-4. , gear Ⅱ shaft 1-5, half gear Ⅰ 1-6, cutting gear Ⅰ 1-7, cutting gear Ⅰ shaft 1-8, cutting motor shaft sprocket 1-9, chain Ⅰ 1-10, sprocket Ⅰ 1-11 , sprocket Ⅰ shaft 1-12, sprocket Ⅱ 1-13, chain Ⅱ 1-14, sprocket Ⅲ 1-15, sprocket Ⅲ shaft 1-16, half gear Ⅱ 1-17, guillotine cutting gear Ⅱ 1-18, guillotine 1- 19. Support Ⅰ1-20, support Ⅱ1-21, support Ⅲ1-22, support Ⅳ1-23, guillotine cutting base plate 1-24, support Ⅴ1-25 and support Ⅵ1-26, guillotine cutting motor 1-1 and guillotine cutting motor shaft 1-2 phase connection, the guillotine motor 1-1 is connected with the guillotine bottom plate 1-24, the guillotine motor shaft 1-2 is connected with the gear I1-3, the gear I1-3 is meshed with the gear II1-4, and the gear II1-4 is connected with ...

specific Embodiment approach 3

[0033] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the first embodiment, the transmission device 2 includes a ratchet shaft bracket 2-1, a gear IV shaft bracket 2-2, a guillotine cutting motor shaft bevel gear 2-3, and a bevel gear I2 -4. Bevel gear I axis 2-5, sprocket IV 2-6, chain III 2-7, sprocket V2-8, sprocket V axis 2-9, half gear III 2-10, gear frame 2-11, gear frame Slide rail 2-12, connecting column 2-13, slide bar 2-14, slide bar slide rail 2-15, rocker I 2-16, rocker shaft 2-17, gear shaft 2-18, gear 2- 19. Ratchet 2-20, ratchet shaft 2-21, gear Ⅲ 2-22, gear Ⅳ 2-23, gear Ⅳ shaft 2-24, sprocket Ⅵ 2-25, chain Ⅳ 2-26, sprocket Ⅶ2-27, sprocket Ⅷ 2 -28, sprocket VIII shaft 2-29, chain V2-30, sprocket bracket 2-31, sprocket bracket shaft 2-32, sprocket IX 2-33, transmission belt 2-34, bevel gear I shaft bracket 2- 35. Sprocket V shaft bracket 2-36 and rocker shaft bracket 2-37, the guillotine motor 1-1 is connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap