Rope hot cutting device

A technology of cutting and equipment, applied in the cutting of textiles and papermaking, textile materials, etc., can solve the problems of easy off-line and bifurcation at the incision position, low work efficiency, and affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

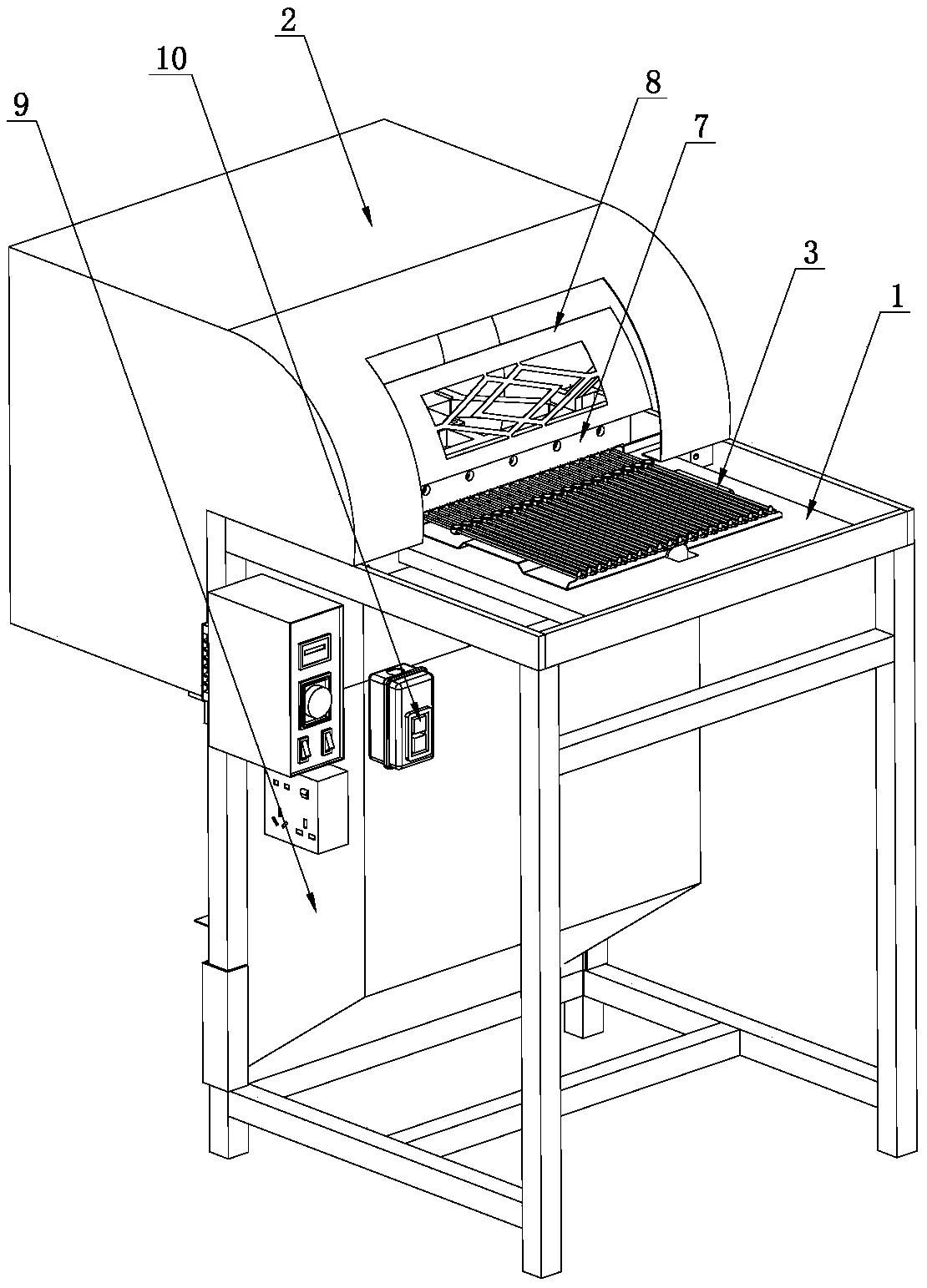

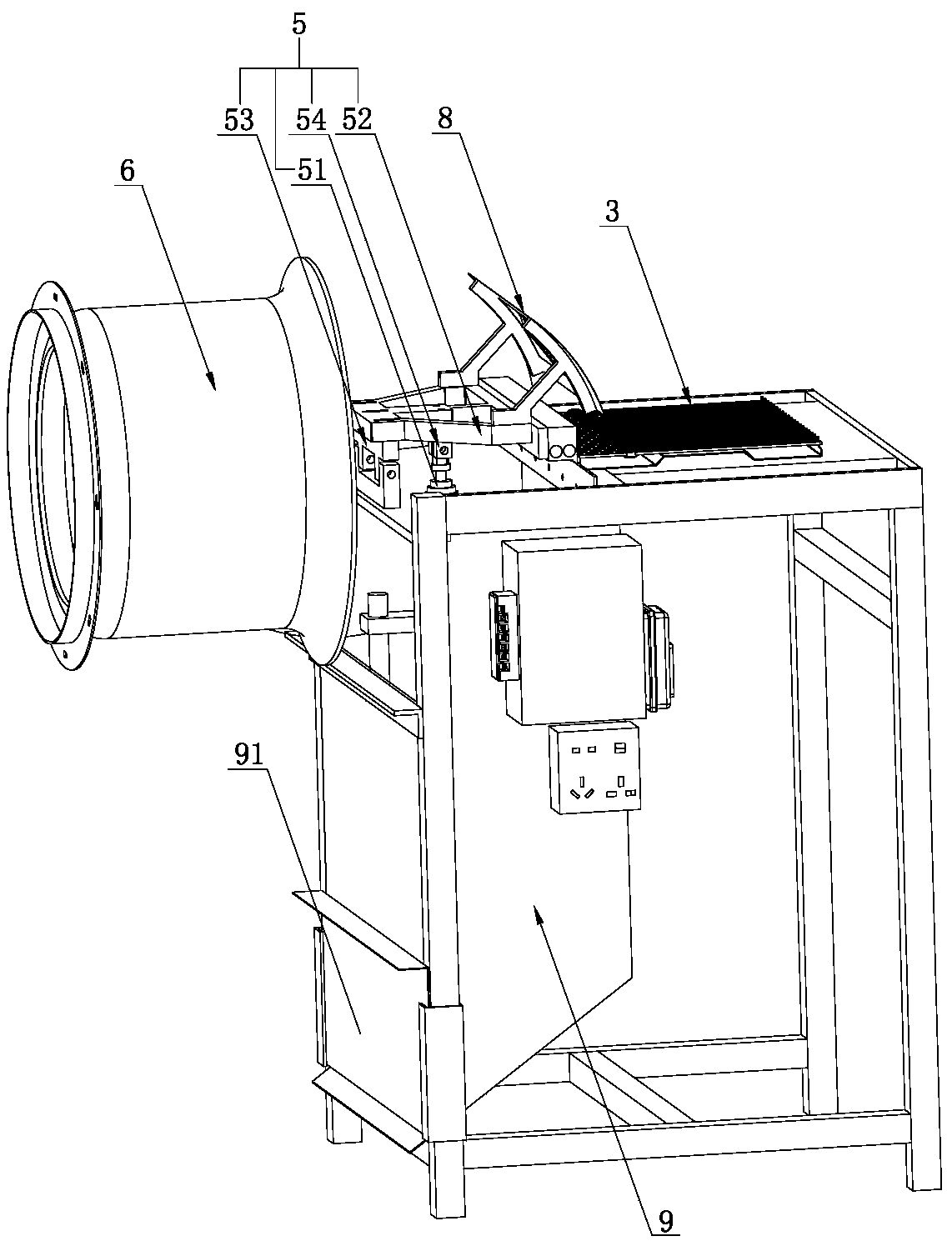

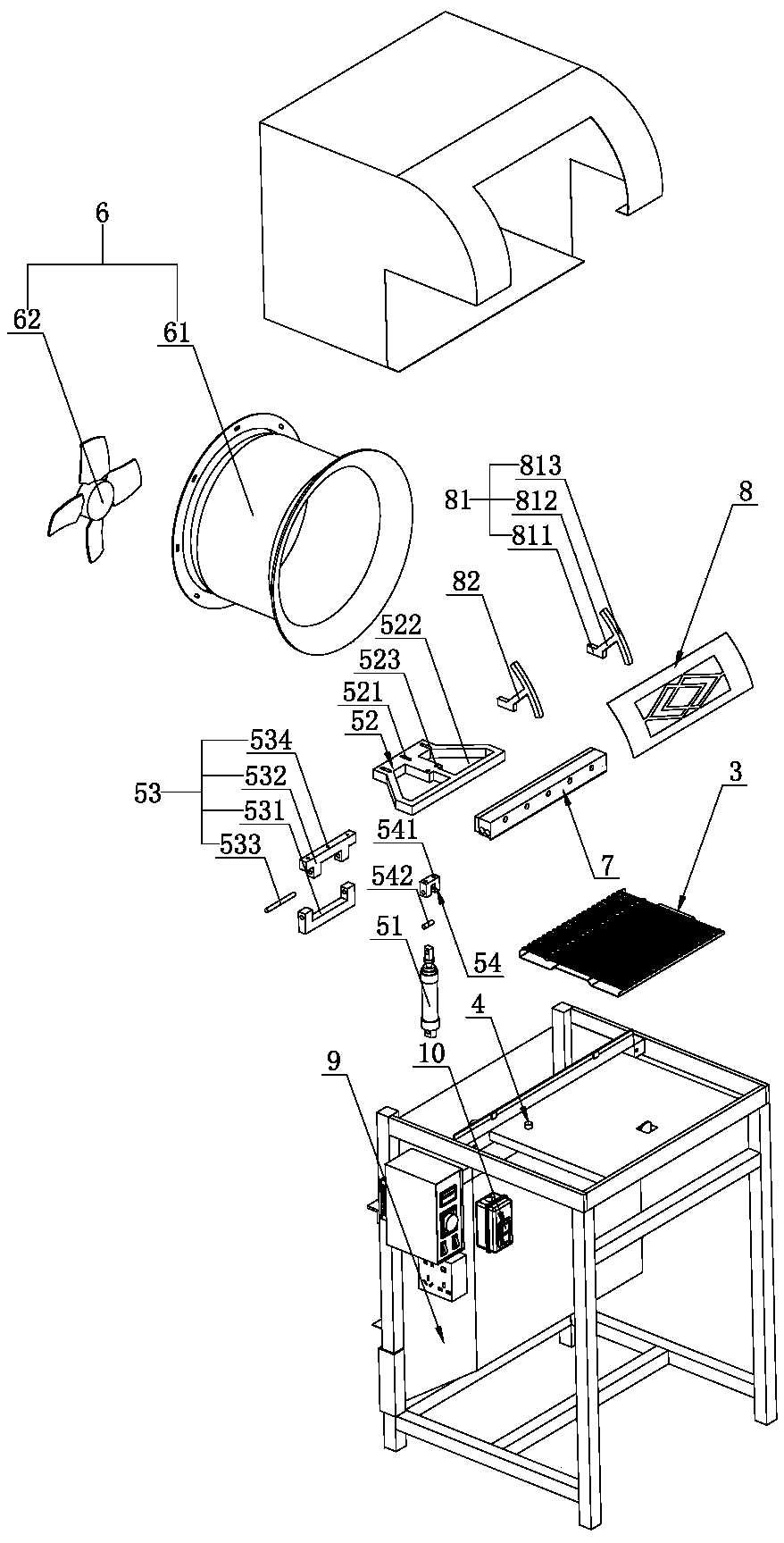

[0037] Such as Figure 1 to Figure 4 As shown, a cord cutting equipment of the present invention includes a machine platform 1, the machine platform 1 is provided with a hot cutting device 2 and a material rack 3, and the machine platform 1 is also provided with a trigger for triggering and controlling the operation of the hot cutting device 2. Control switch 4, said hot cutting device 2 is provided with a power assembly 5 and a ventilation device 6, the output end of said power assembly 5 is connected with a hot knife 7, and the top of said power assembly 5 is provided with a protective cover 8.

[0038] When working, the worker puts multiple rope buckles into the material rack 3 one by one, and then places the material rack 3 loaded with multiple rope buckles on the machine table 1, and aligns the rope end of the rope buckle with the cutting position of the hot cut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap