Pump valve quick coupling quick assembly method and device

An assembly device and assembly method technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high failure rate, heavy manual operation workload, etc., achieve high efficiency, low failure rate, reduce The effect of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

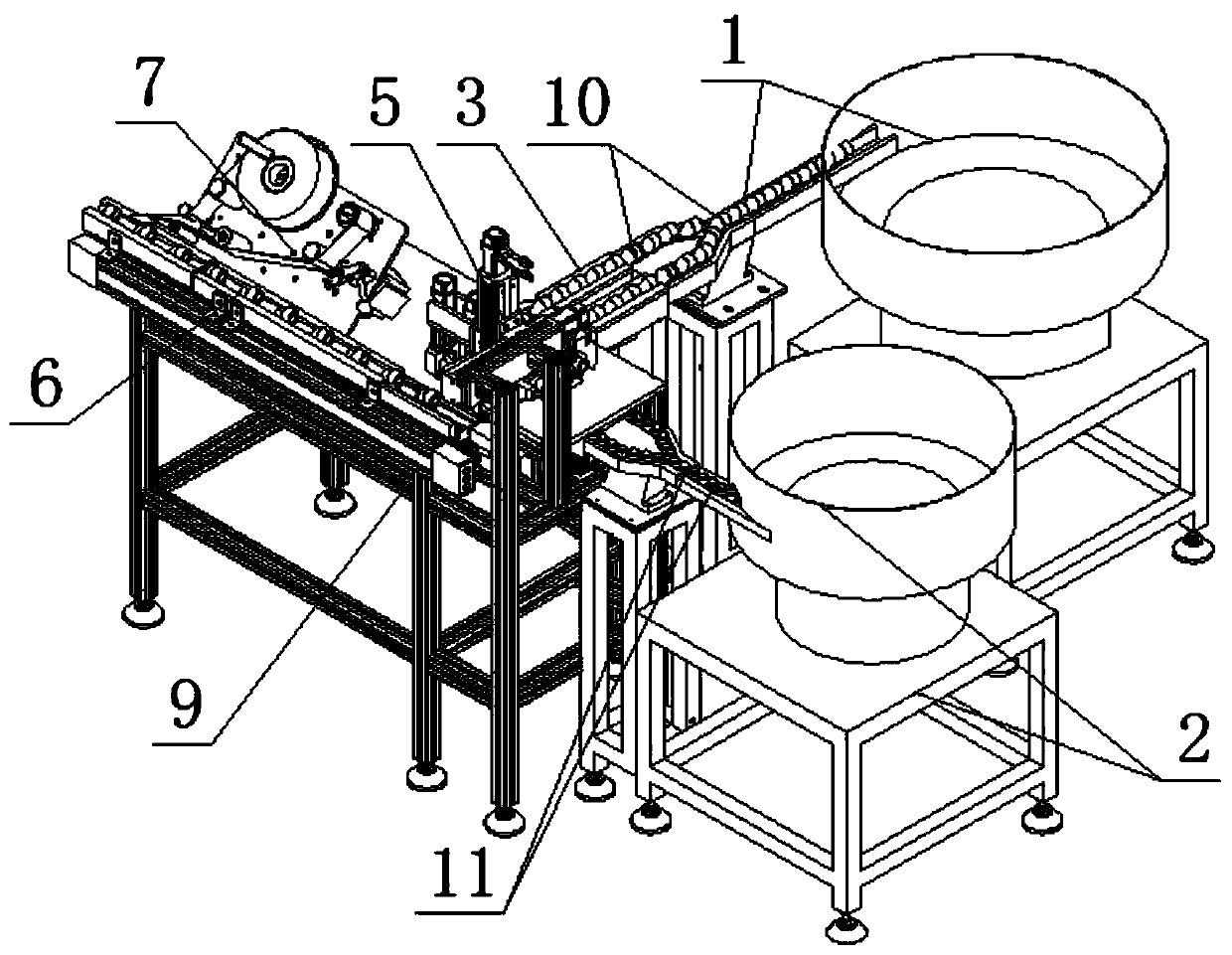

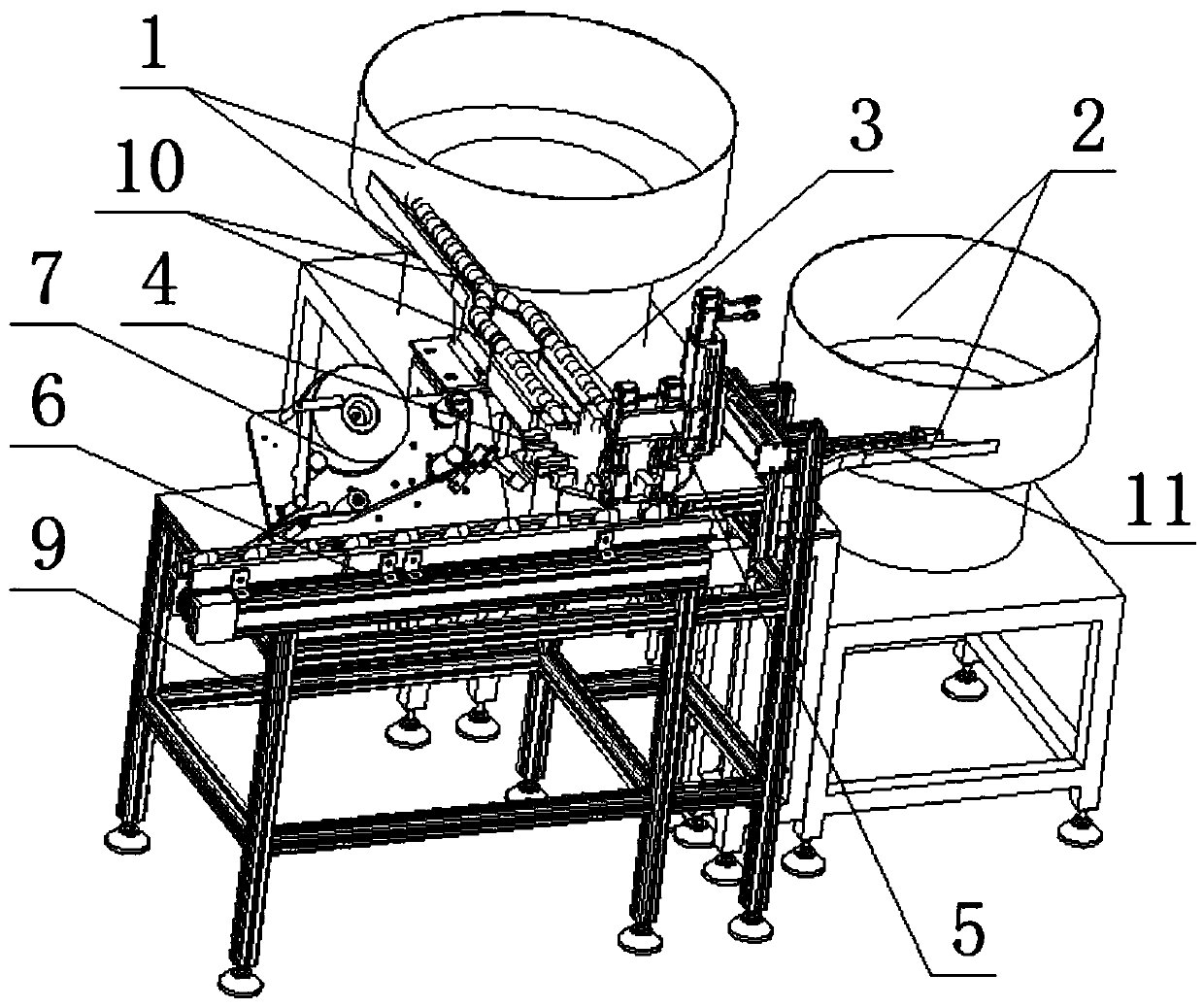

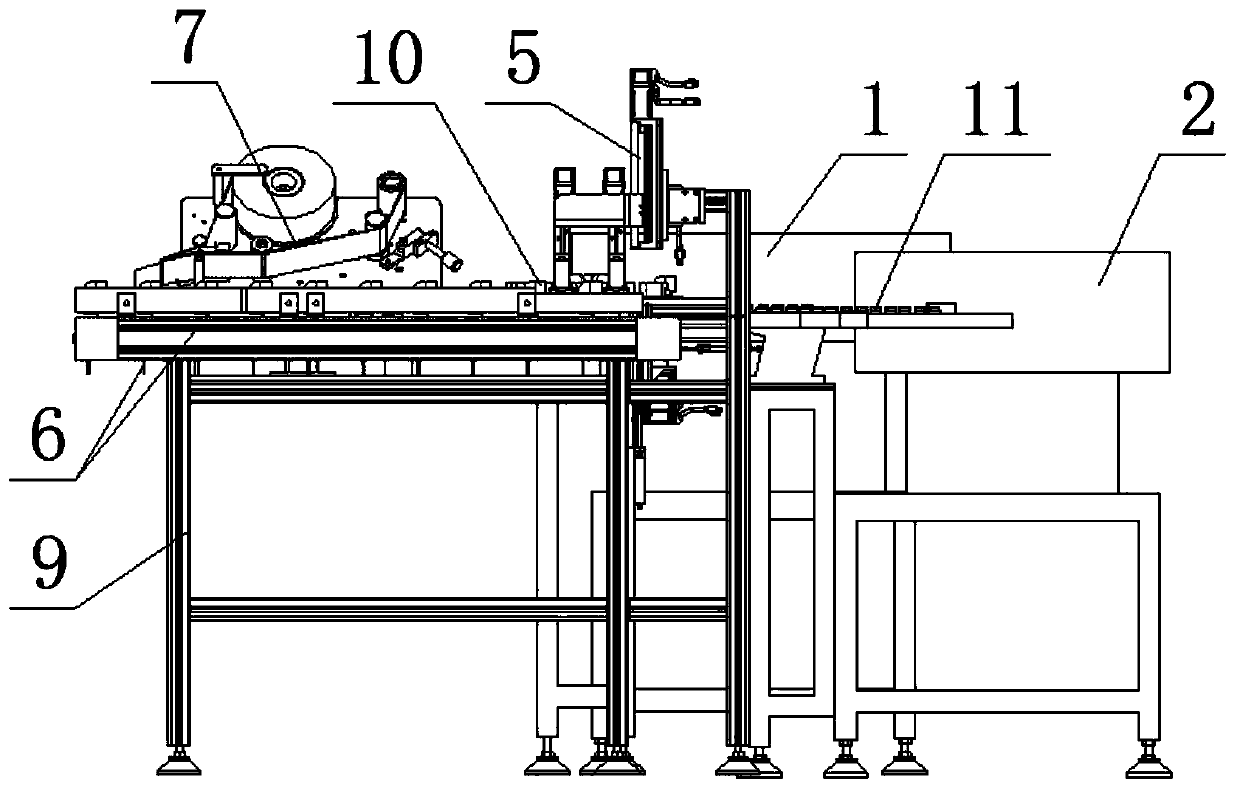

[0032] refer to Figure 1-Figure 9 , the present invention comprises the following steps:

[0033] Step 1: The joint is fed to the turntable: the joint is placed in the vibrating plate of the joint feeding mechanism 1, and the material is vibrated by the vibrating plate and divided into two by the Y-shaped guide rail, and then sent to the pneumatic feeding head 3, and the feeding of the pneumatic feeding head 3 The cylinder 35 sends the joint to the turntable of the turntable mechanism 4;

[0034] Step 2: The turntable is transferred to the next station: the turntable motor of the turntable mechanism 4 drives the turntable to turn 90 degrees, and moves the joint to the left end of the plug feeding mechanism 2;

[0035] Step 3: The plug is fed to the top of the press-fitting mechanism: the plug is placed in the vibrating plate of the plug feeding mechanism 2, and the material is vibrated by the vibrating plate and divided into two by the Y-shaped guide rail, and then sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com