Locking and releasing structure driven by shape memory alloy strip

A locking and releasing, memory alloy technology, applied in the direction of the docking device of the spacecraft, can solve the problems of severe shock and vibration, unstable safety, pyrotechnic pollution, etc., achieve good impact resistance, short unlocking time, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

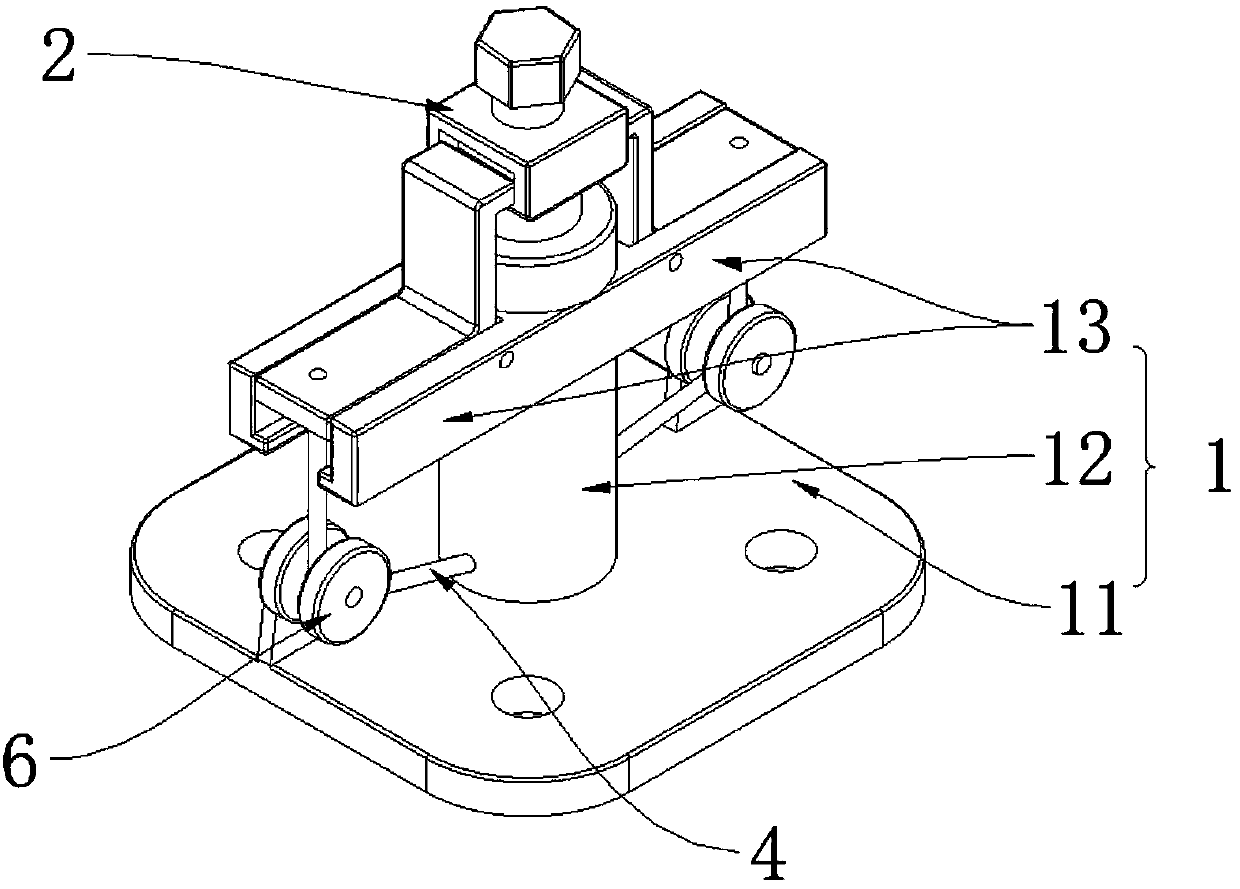

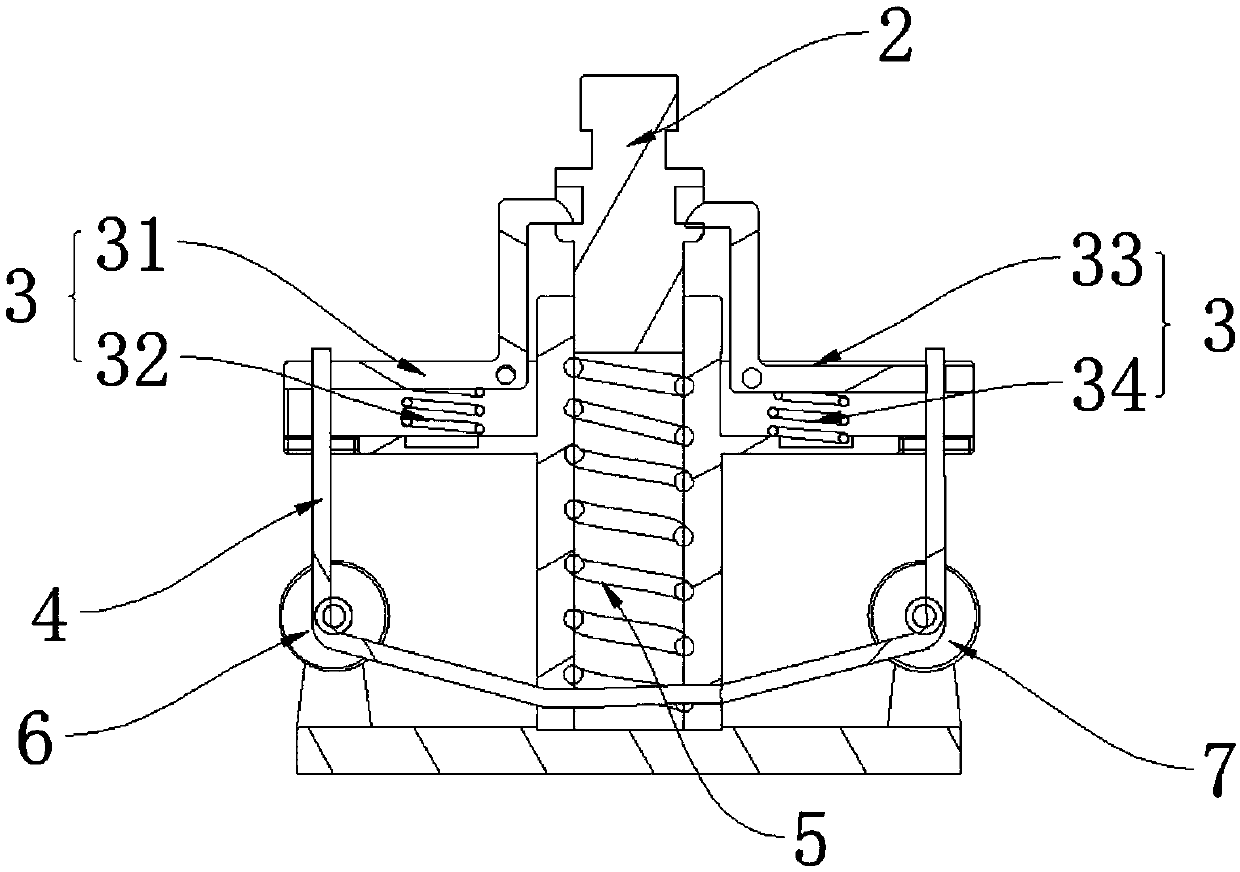

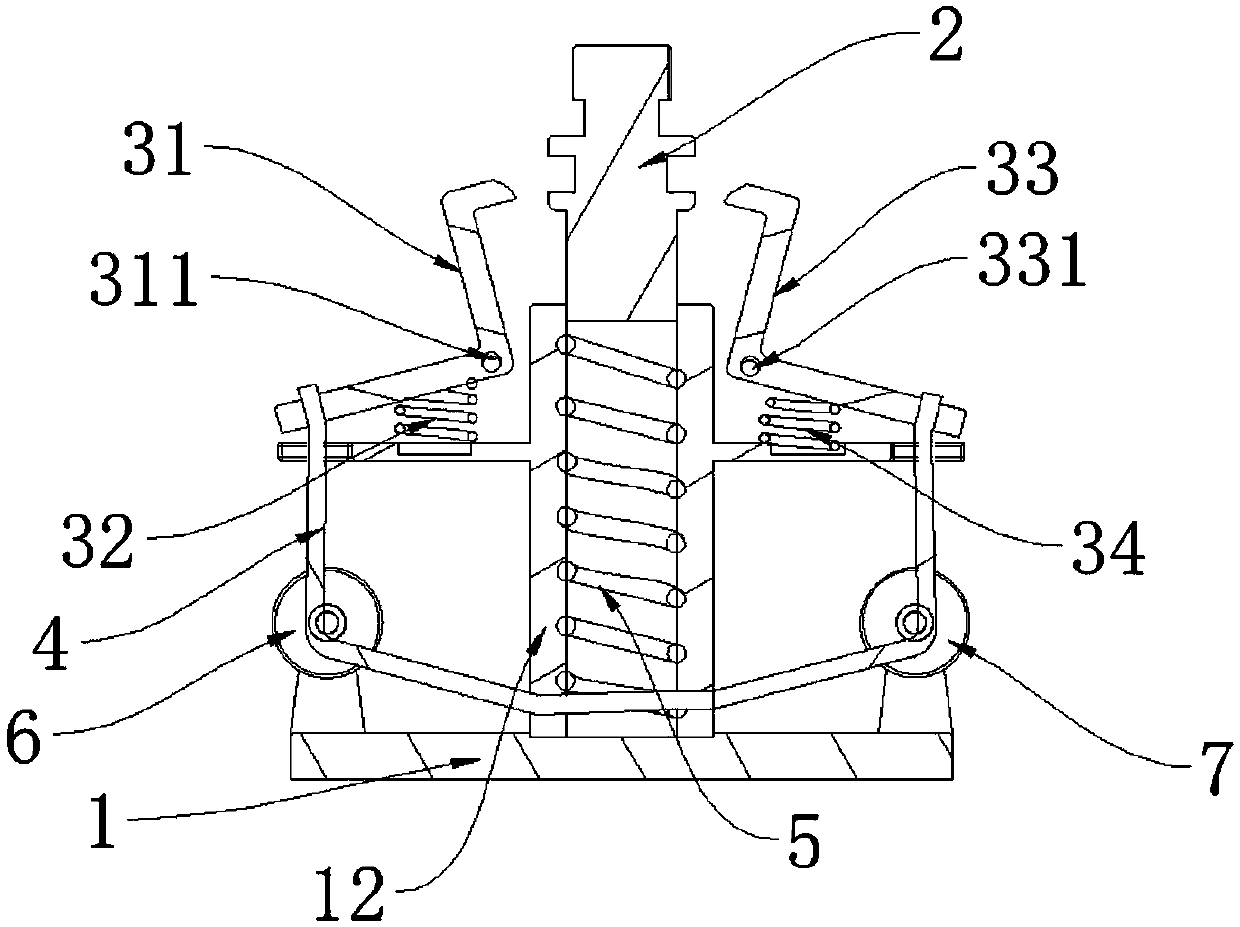

[0037] combine figure 1 , figure 2 and image 3 as shown, figure 1 It is a structural schematic diagram of the locked state of the locking and releasing structure driven by the shape memory alloy strip according to the present invention; figure 2 Yes figure 1 sectional view of image 3 It is a sectional view of the unlocked state of the locking and releasing structure driven by the shape memory alloy strip according to the present invention. In order to solve the technical problem that only a single unlocking and releasing can be realized in the unlocking process of the traditional pyrotechnic separation device, this embodiment discloses a locking and releasing structure driven by a shape memory alloy strip. The lock release structure driven by shape memory alloy strips includes a support frame, and the support frame includes: a support frame 1, which includes a sleeve 12 and at least one support arm 13 connected to the sleeve 12; an ejector 2 , which is movably arrang...

Embodiment 2

[0052] combine figure 1 , figure 2 and image 3 As shown, the locking and releasing structure driven by the shape memory alloy strip described above, the difference between this embodiment and the above embodiment is that the locking and releasing structure driven by the shape memory alloy strip further includes: locking The assembly 3 also includes a second return compression spring 33 and a second hook 34, the support frame 1 includes two support arms 13, and the two support arms 13 are symmetrical about the sleeve 12, and the locking and releasing structure driven by the shape memory alloy strip also Including the first pulley 6 and the second pulley 7; the second hook 34 and the first hook 31 are mirror-symmetrically arranged with respect to the ejector 2; the second return compression spring 34 and the first return compression spring 32 are arranged symmetrically with respect to the ejector 2 In the support arm 13, the second reset compression spring 34 is located belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com