A fox fur carding device based on fur processing

A fox and fur technology, applied in the field of fur processing, can solve problems such as unfavorable processing, low work efficiency, and difficult control, and achieve the effects of cost saving, good cleaning effect, and improved carding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

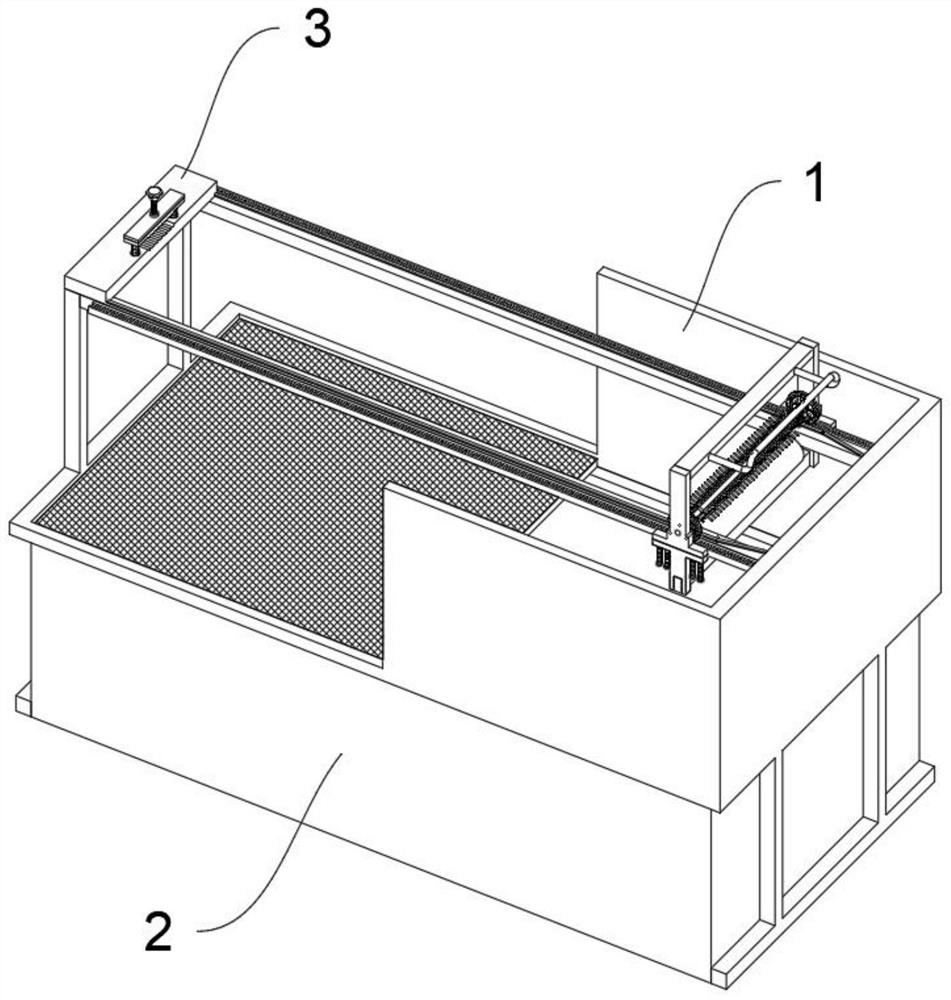

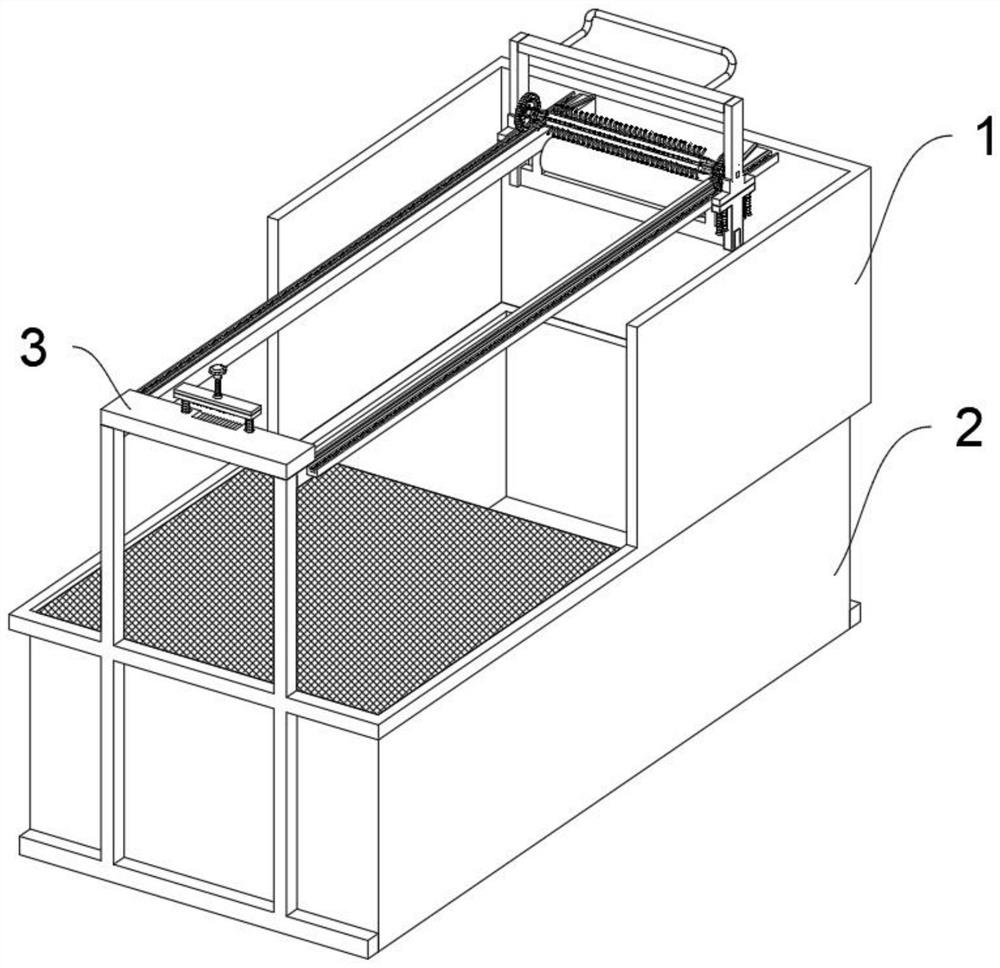

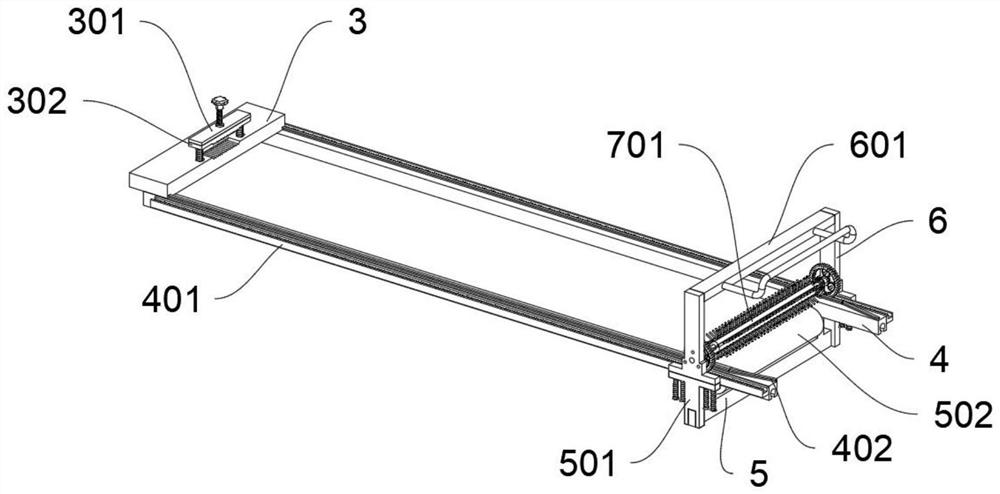

[0031] see Figure 1 to Figure 5 , Figure 7 and Figure 8 , an embodiment provided by the present invention: a fox fur combing device based on fur processing, including a frame body 1; the bottom of the frame body 1 is an empty frame structure, and the bottom of the frame body 1 is placed with a collection box that can be placed in the same length and width. 2; the top of one side of the frame body 1 is a semi-enclosed structure; the middle side of the frame body 1 is fixedly provided with a filter screen; the top of the other end of the frame body 1 is fixed with a fixing device 3 by bolts; wherein, the fixing device 3 also includes: The fixing bar 301 and the pressing bar 302; the top of the fixing device 3 is fixedly provided with a fixing bar 301 through a column, the top of the fixing bar 301 is provided with bolts, and the abutting surface between the fixing bar 301 and the fixing device 3 is set as a matching tooth A compression bar 302 is slidably arranged between t...

Embodiment 2

[0033] On the basis of Example 1, see Image 6 , an embodiment provided by the present invention: a fox fur combing device based on fur processing, also includes a cleaning mechanism 8, the outer guide rail 402 is slidably provided with a cleaning mechanism 8; the cleaning mechanism 8 also includes a guide pulley 801, The balance frame 802 and the screw ring 803; the bottom of the cleaning mechanism 8 is movably provided with four sets of guide pulleys 801 through the rotating shaft; the top of the cleaning mechanism 8 is provided with a balance frame 802 through the rotation of the shaft, and the outer side of one end of the balance frame 802 is fixedly arranged through a threaded structure There is a coil 803.

Embodiment 3

[0035] On the basis of Example 1 and Example 2, see Figure 5 , Figure 7 and Figure 8, an embodiment provided by the present invention: a fox fur combing device based on fur processing, the brush shaft 7 also includes a brush roller 701 and a brush 702; roller 701, and a plurality of sets of brushes 702 are fixedly arranged on the outside of the brush roller 701;

[0036] Among them, it also includes a ring-type connecting rod seat 9, the outer end of the cleaning mechanism 8 is fixedly provided with a needle roller bearing through the interference fit of the screw ring 803, and the ring-type connecting rod seat 9 is fixed outside the needle roller bearing. The ring-type connecting rod seat 9 includes a connecting rod 901 and a cleaning bar 902; the outer side of the ring-type connecting rod seat 9 is provided with six sets of connecting rods 901 through the rotation of the shaft, and the cleaning bars are arranged between the connecting rods 901 on both sides through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com