Disc-type motor

A disc motor and control circuit technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low operating stability and accuracy of disc motors, and solve the problem of low operating stability and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

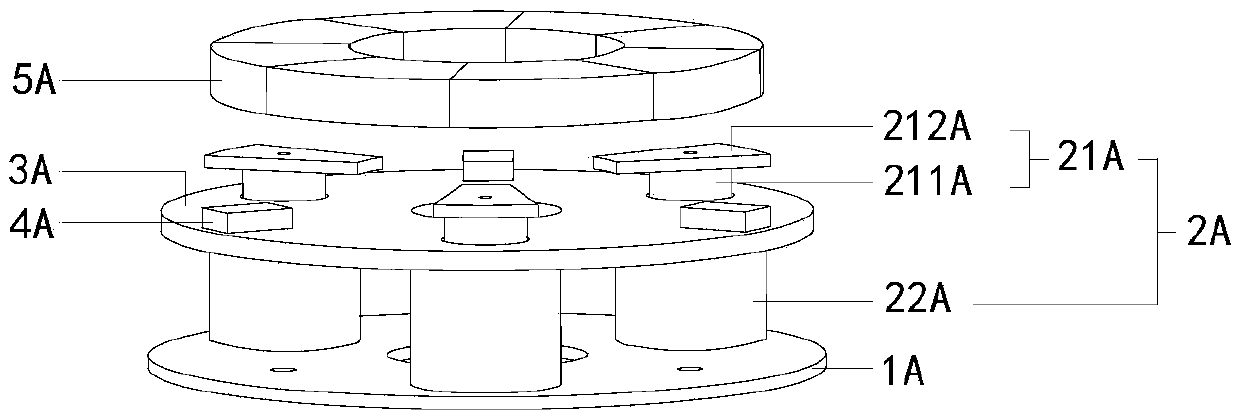

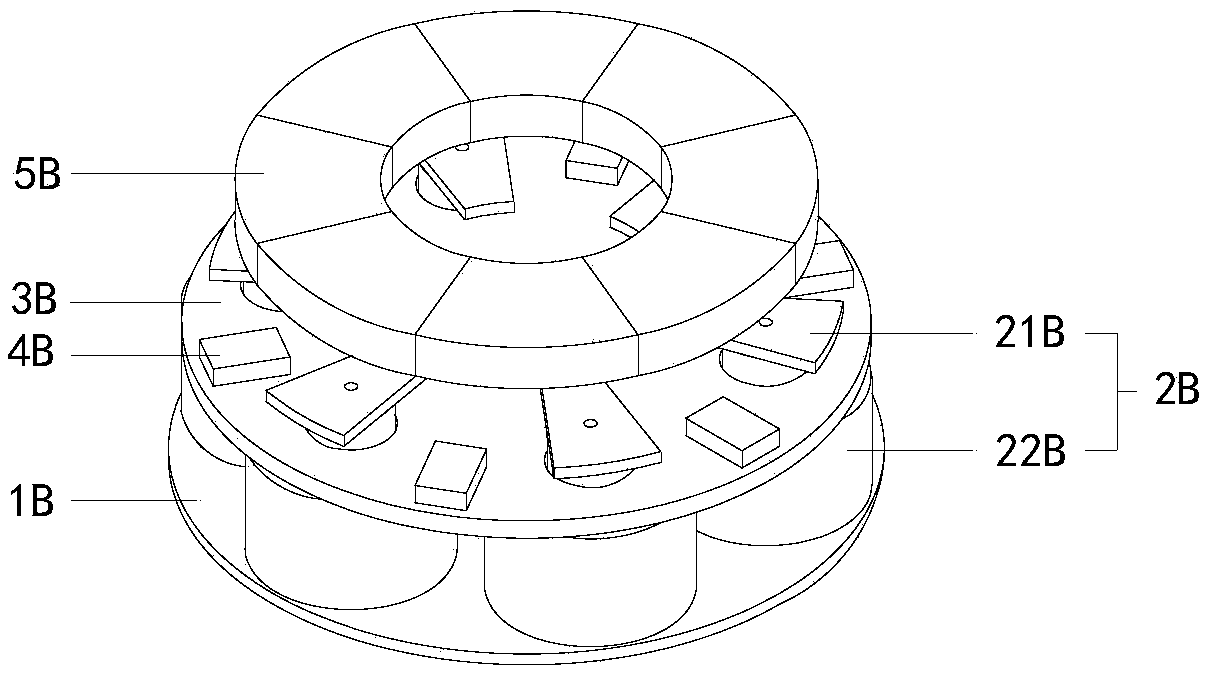

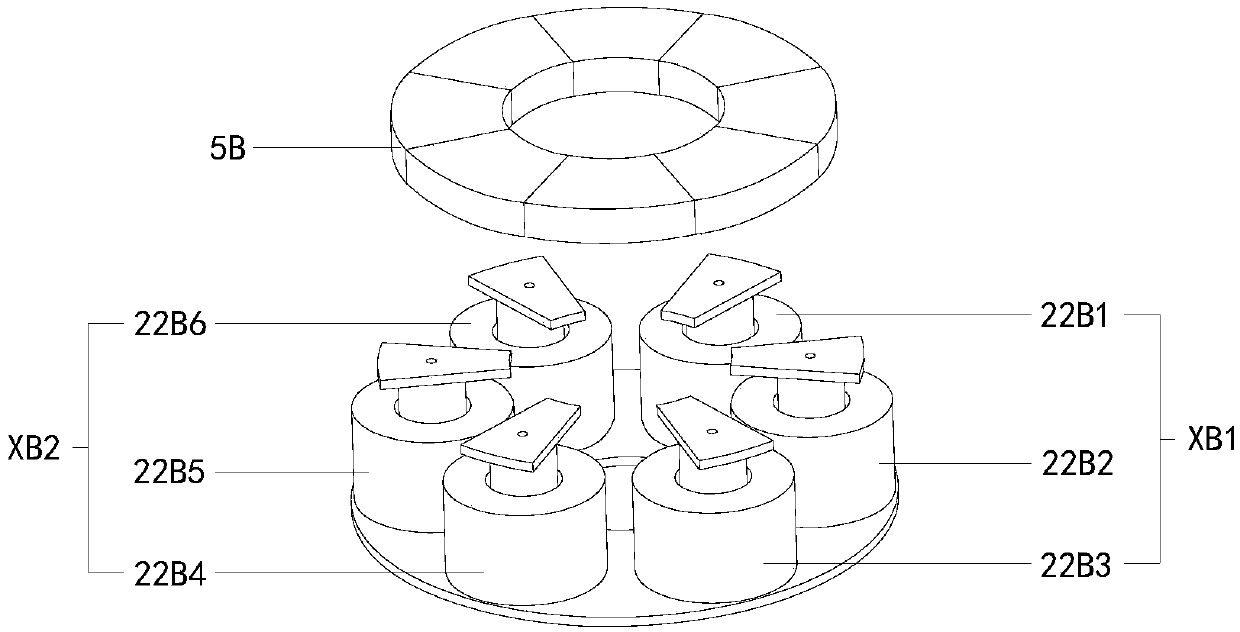

[0036] The disc motor of the present invention includes a stator, a rotor, a position sensor, and a control circuit; the stator includes a winding unit, the winding unit is placed between the stator and the rotor, and the number of winding units is 3N , Every three adjacent winding units form a three-phase winding, and N is a natural number greater than or equal to 1; the position sensor is opposite to the rotor, and the position sensor is used to detect the rotation speed and the floating height of the rotor; The control circuit is electrically connected to the winding unit and the position sensor, and the control circuit is used to receive the detection result of the position sensor, and thereby control the rotation speed and the suspension height of the rotor through the winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com