Air energy injection enthalpy-increasing ultra-low temperature cascade dryer

A technology of increasing enthalpy by air injection and ultra-low temperature, applied in dryers, drying, refrigerators, etc., can solve the problems of poor color consistency of baked products, affecting compressor power and operating efficiency, and large temperature differences of materials, etc., to achieve Good promotion and application prospects, improved system economic performance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

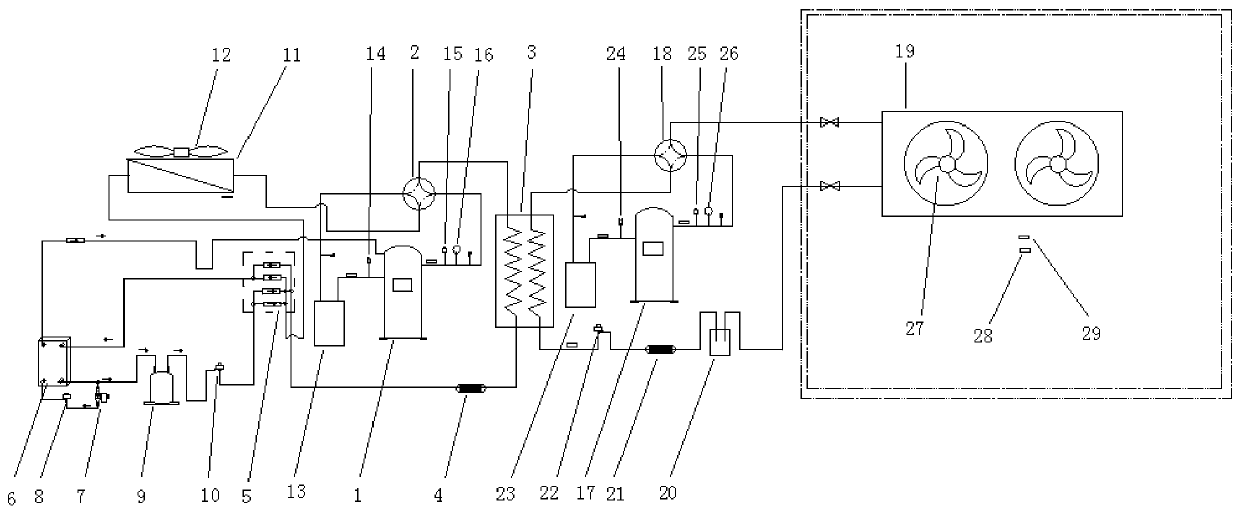

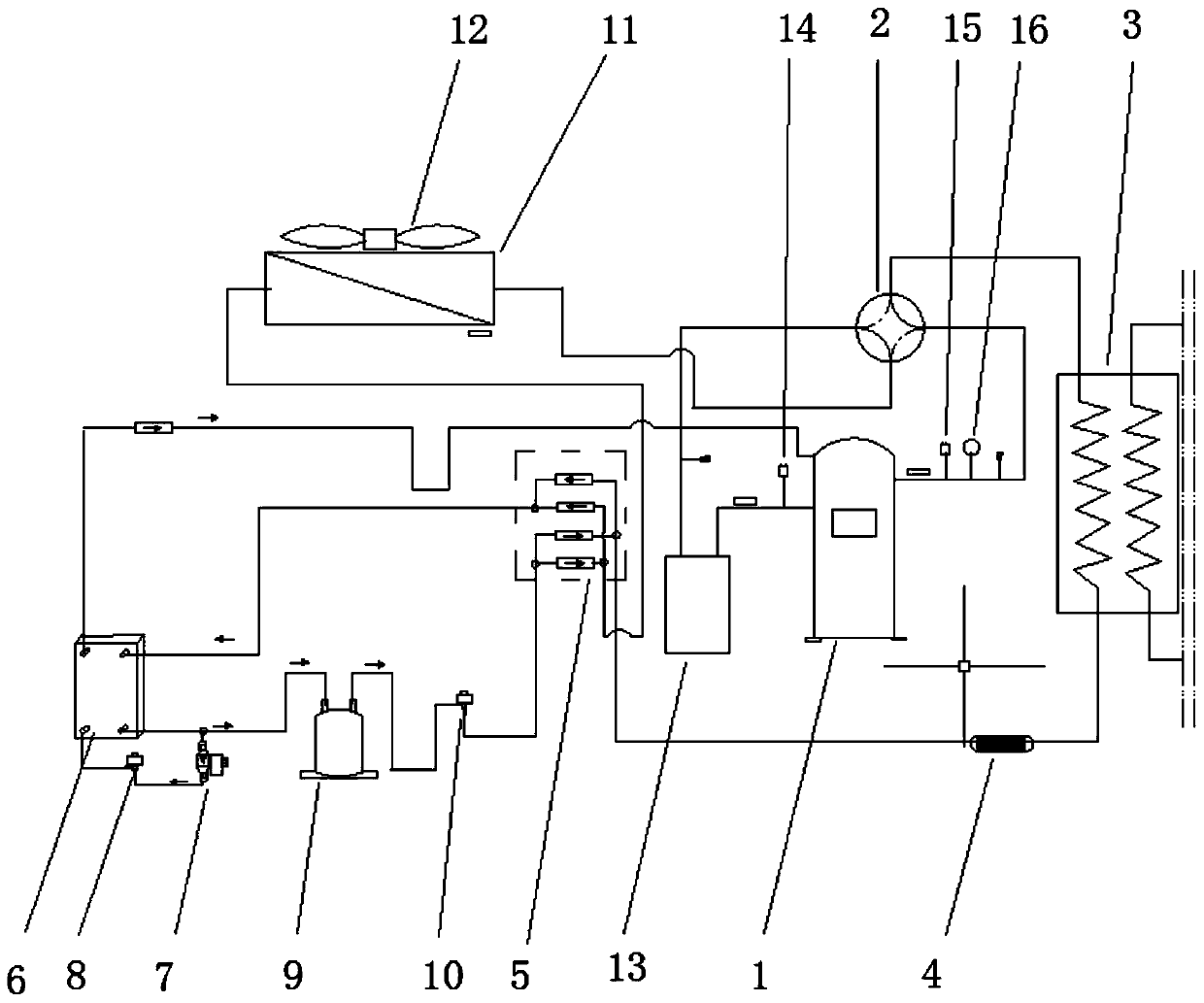

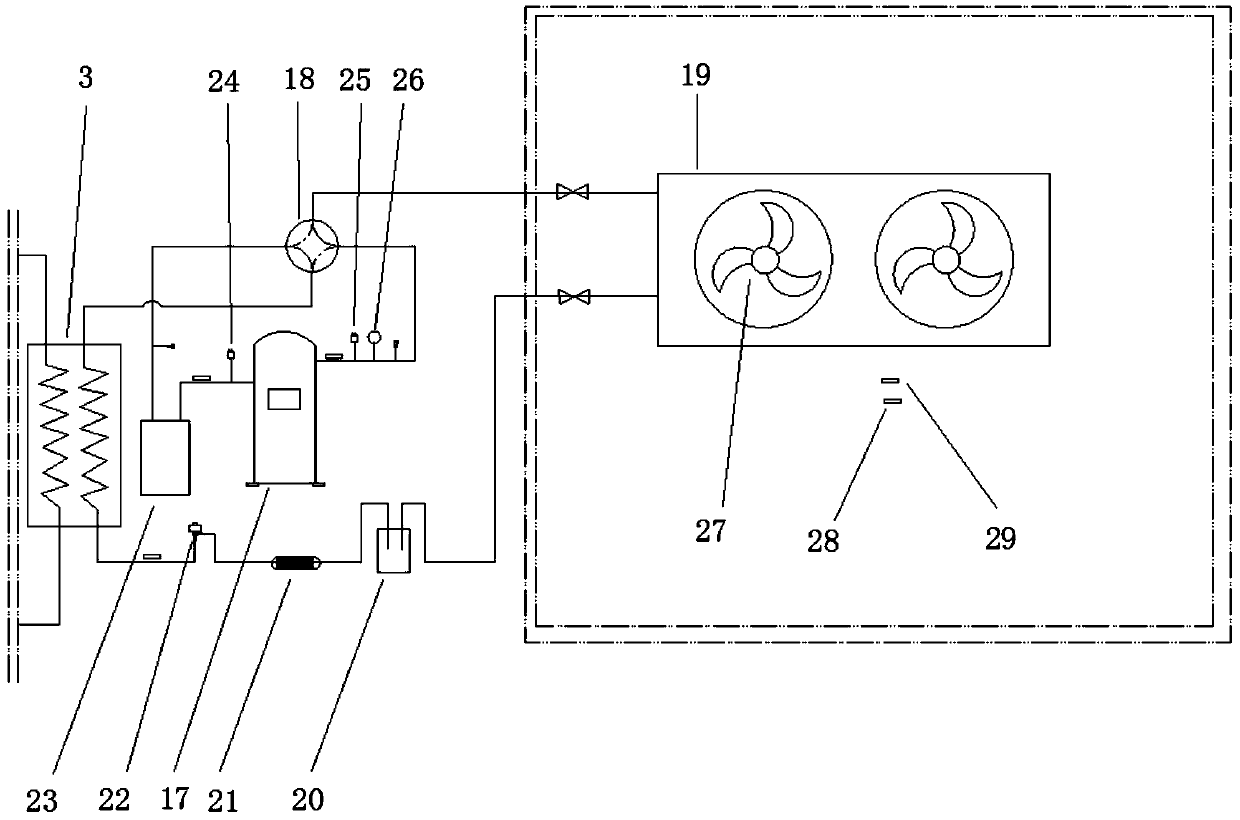

[0022] In the following, the ultra-low temperature cascade dryer of the present invention will be further described in detail in conjunction with specific embodiments and drawings.

[0023] refer to Figure 1 to Figure 3 , an ultra-low temperature cascade dryer that can increase enthalpy by air injection, including a first circulation system and a second circulation system, the first circulation system is a refrigeration system, the second circulation system is a heating system, and the The refrigerant gas evaporated in the first circulation system exchanges heat with the condensed liquid refrigerant in the second circulation system through the intermediate heat exchanger, so that after the heat in the air is evaporated and absorbed in the first circulation system, the refrigerant gas passes through the compressor Provide heat to the second circulation system through the intermediate heat exchanger; the first circulation system is provided with an auxiliary enthalpy increasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com