Foldable fire-fighting pipeline roof mounting lifting device

A technology of fire-fighting pipelines and lifting devices, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of low installation efficiency and high labor intensity, and achieve the effects of improving installation efficiency, reducing labor intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

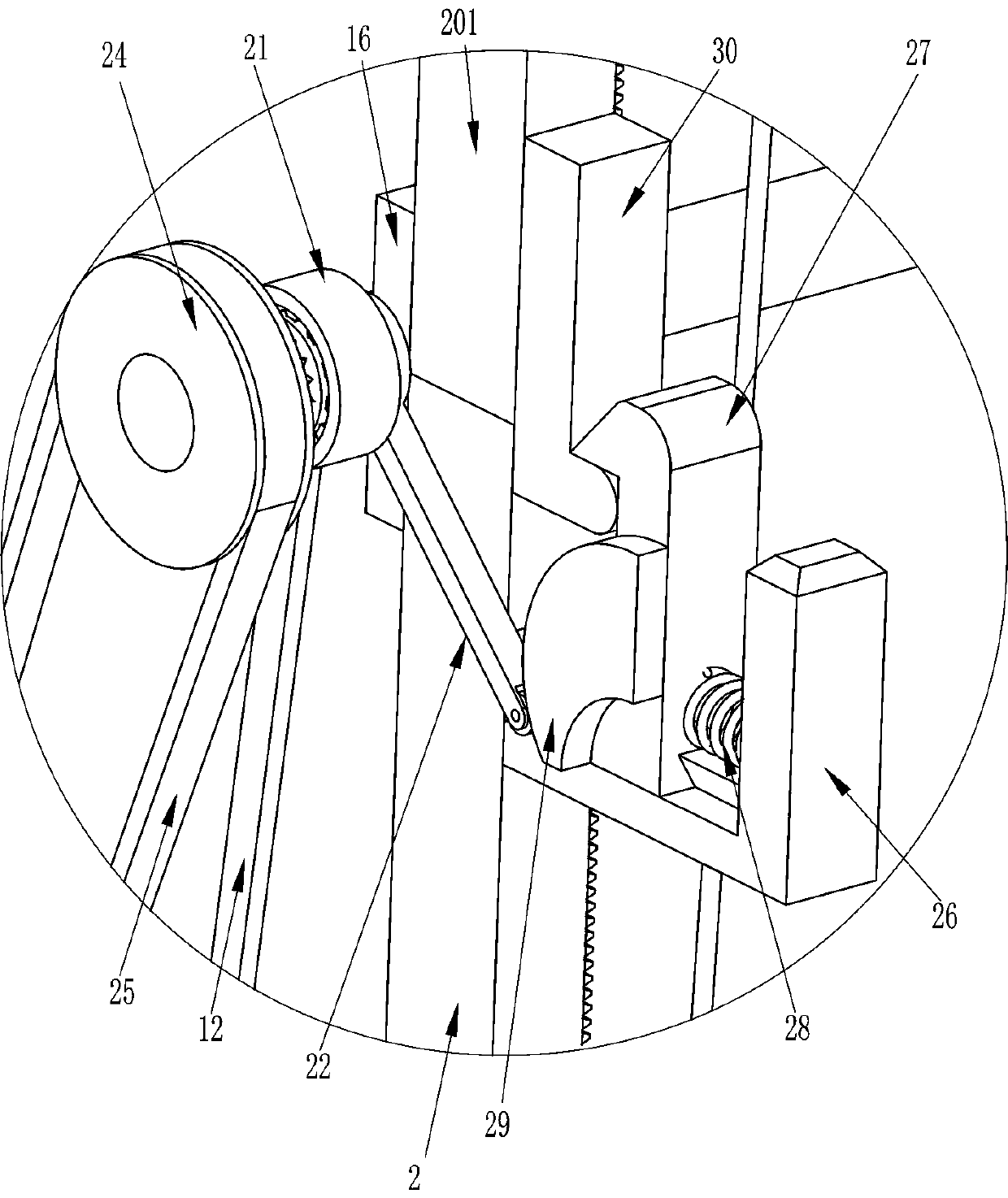

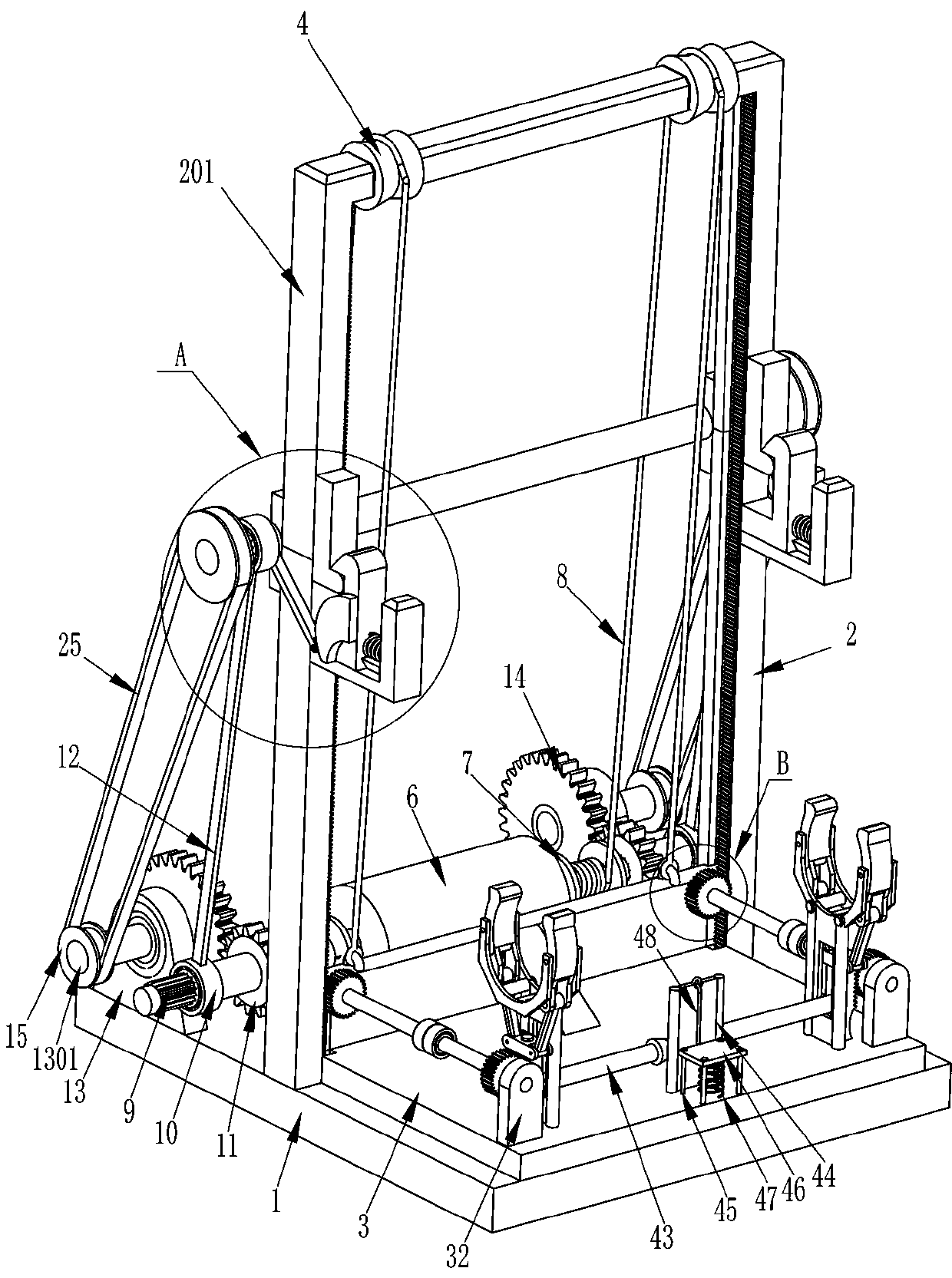

[0023] see Figure 1-Figure 4 , a kind of foldable fire-fighting pipe roof installation lifting device, including base 1, lifting frame 2, swing frame 201, lifting mechanism, biaxial motor 6 and turning mechanism, the left and right sides of the middle of the top of base 1 are fixedly connected with Lifting frame 2, a swinging frame 201 is hinged between the tops of the lifting frame 2 on the left and right sides, a lifting mechanism is provided between the swinging frame 201 and the lifting frame 2, and a flipping mechanism is provided between the lifting frame 2 and the base 1 and the rear side of the swinging frame 201. mechanism, the biaxial motor 6 is installed on the top rear side of the base 1, and the biaxial motor 6 is connected with the turning mechanism and the lifting mechanism.

[0024] The lifting mechanism includes an L-shaped slide plate 3, a scroll wheel 4, a suspension ring 5, a reel 7, a wire rope 8, a support rod 36 and a U-shaped block 37, and the left and...

Embodiment 2

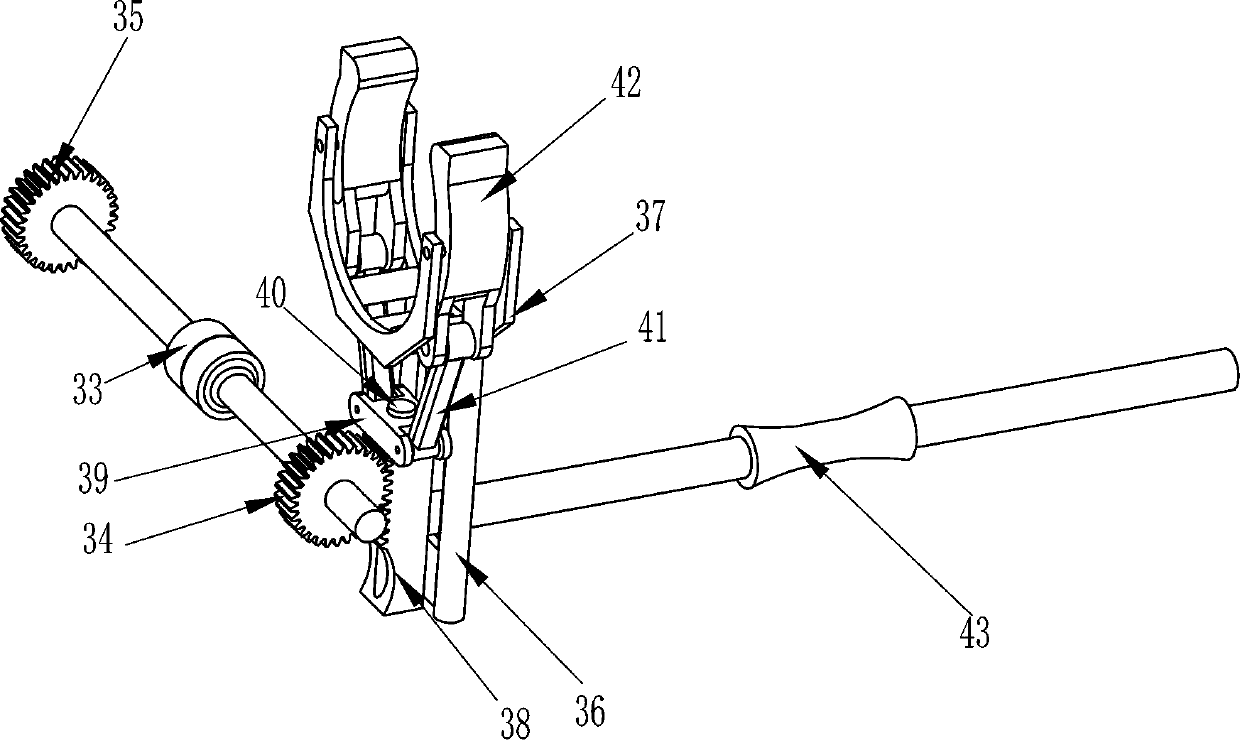

[0030] see figure 1 , figure 2 with Figure 5 Compared with Embodiment 1, the main difference of this embodiment is that this embodiment also includes a first rack 31, a second support plate 32, a one-way shaft 33, a third gear 34, a fourth gear 35, a second Rack 38, connecting block 39, the first slide bar 40, the second push rod 41, clip block 42 and pull bar 43, the left and right sides of the front side of the inner bottom of the L-shaped slide plate 3 are all affixed with the second support plate 32, the second The support plate 32 is located at the outside of the support rod 36, the top of the second support plate 32 is rotatably connected with a one-way shaft 33, the rear end of the one-way shaft 33 is fixedly connected with a fourth gear 35, and the front portion of the one-way shaft 33 is fixedly connected with a third The gear 34, the left and right sides of the inner bottom of the L-shaped skateboard 3 are fixedly connected with the first slide bar 40, the first ...

Embodiment 3

[0033] see figure 1 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that this embodiment also includes a third support plate 44, a second slide bar 45, a pedal 46, a second elastic member 47 and a pull wire 48, L Four second slide bars 45 are fixedly connected to the middle part of the inner bottom of the type skateboard 3, and pedals 46 are slidingly provided between the four second slide bars 45. The second elastic member 47 is connected with a pull wire 48 at the middle part of the rear side of the pedal 46, and the third support plate 44 is fixedly connected with the front middle part of the inner bottom of the L-shaped slide plate 3, and the third support plate 44 is located between the pull bar 43 and the second slide bar 45. The tail end of the pull wire 48 is fixedly connected to the middle of the pull rod 43 around the top of the third support plate 44 .

[0034] When the fire-fighting pipeline is placed between the u-shaped blocks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com